New Coating Techniques for Optics in High-Power Laser Systems

Optical Coatings for High-power Lasers

Author: Dr.-Ing. Hansjörg Rohde, Product Manager LASER COMPONENTS Germany

Published: LP.PRO 06/2025

Download PDF (German version only)

With the trend towards higher laser power in material processing, the demands placed on optical components are also increasing. Optical components must have a high reflectivity and laser damage threshold (LIDT) with minimal thermal drift.

Optical coatings play a key role in achieving these results: they have a strong influence on the performance, stability, and efficiency of the entire laser process.

Versatile Optics

for Laser Material Processing

Optics guide the laser beam from the source to the workpiece, for which the following requirements are crucial: maintaining beam quality, minimizing power losses, and safeguarding high thermal stability. Modern manufacturing processes also integrate high-precision diagnostic optics for online process monitoring, which analyze the interactions between the laser beam and the material.

A typical laser processing head (Fig. 1) contains various optics with specific requirements:

- The (aspherical) collimator lens focuses the divergent laser beam and guides it to the processing lens with the least possible loss. It must offer high wavefront quality (≤ λ/10), high transmission, low self-absorption, and thermal stability with minimal focus drift.

- The beam splitter ensures a defined splitting ratio and a high wavefront fidelity, often independent of the polarization. It is used to constantly monitor the laser beam. The coating is adapted to the laser and diagnostic wavelengths.

- Dichroic mirrors separate processing and diagnostic wavelengths spectrally with high transmission for the process wavelength and defined reflection for the diagnostic area.

- The processing lens focuses the laser beam towards the workpiece, with the highest demands being placed on optical precision and thermal stability. Cutting optics are also characterized by particularly low absorption in order to minimize thermal lens effects and focus drift.

- The protective window protects internal optics from contamination. A suitable anti-reflective coating minimizes absorption and prevents thermally induced deformation.

As optical systems with dielectric layers become more and more complex, optical interference coatings (OICs) are becoming increasingly important for these optics. OICs consist of alternating transparent layers with a high and low refractive index and are deposited precisely in the nanometer to micrometer range.

Transmission and reflection can be precisely controlled for specific wavelengths by constructive and destructive interference. The optical properties depend directly on the layer sequence, the material constants, and the precision of the coating thickness.

In high-power laser systems, OICs enable anti-reflective (AR) coatings, highly reflective (HR) mirrors, bandpass filters, and dichroic beam splitters. They ensure low-loss beam guidance, high thermal load capacity, and enable spectrally selective process monitoring (e.g., using optical coherence tomography (OCT)).

Manufacturing Optical Coatings

Comparison of Different Technologies

Even the choice of substrate has a major influence on the subsequent performance of the optics. Materials with low self-absorption minimize thermal lensing effects. LASER COMPONENTS uses three established processes to produce optical interference layers: plasma ion-assisted deposition (PIAD), ion beam sputtering (IBS) and electron beam evaporation (e-beam/PVD).

The choice of method depends on the requirements for absorption, layer density, environmental stability, and the cost effectiveness of the respective application. The list shows the advantages and disadvantages of the techniques.

Comparison of coating technologies

Electron beam physical vapor deposition (e-beam/PVD)

- Principle: Vaporization of the material by an electron beam in a vacuum

- Advantage: Cost efficient, high throughput

- Disadvantage: Higher roughness, lower layer density, limited thermal stability, higher optical losses

- Application: Standard optics, base coatings

Plasma-assisted ion deposition (PIAD)

- Principle: Combination of e-beam evaporation with additional plasma for layer concentration

- Advantage: Ultra-dense, moisture-resistant layers, robust against environmental influences, low drift

- Disadvantage: Surfaces with high roughness and possible defects, higher absorption, medium to high throughput

- Application: Protective windows, AR coatings

Ion beam sputtering (IBS)

- Principle: Material is detached from the medium by ion bombardment and placed on the substrate

- Advantage: Precise layer control, low roughness, very low absorption, highest stability

- Disadvantage: High costs, slow to medium throughput, high layer tension

- Application: Precision filters, diagnostic mirrors, high-performance optics

Process Parameters

for Improving Optical Characteristics

Specifically controlling the process parameters such as gas flow, coating rate, and bias significantly influences the absorption, coating structure, and resilience of the coatings produced.

One specific example of this is the regulation of the oxygen flow during the separation of hafnium-based coatings using PIAD: A reduction in the oxygen content during the coating process leads to significantly lower absorption (Fig. 2). Protective windows coated in this way for high-performance cutting processes or additive manufacturing significantly reduce thermal lens effects during the process.

This result is just a first step towards optimizing the entire coating and underlines the potential of systematic process parameter adjustments.

The optical properties can also be further improved by subsequent processes. Systematic annealing of the coatings significantly increases transmission and the laser damage threshold: An AR coating designed at 2940 nm shows an increase in transmission from 96% to over 99% after several hours (four hours) of annealing at 700°C, which means 3% less loss (Fig. 3).

Customized Layer Design

for Diagnostic Optics

A precise spectral separation of processing and diagnostic wavelengths is essential for modern quality assurance systems in industrial laser material processing. Diagnostic mirrors have two central tasks: They ensure low-loss transmission or reflection of the process wavelength and at the same time enable the selective detection of diagnostic information. Their development requires the highest precision in coating design, as reflection and transmission ranges must be precisely matched to the specific process and diagnostic signals.

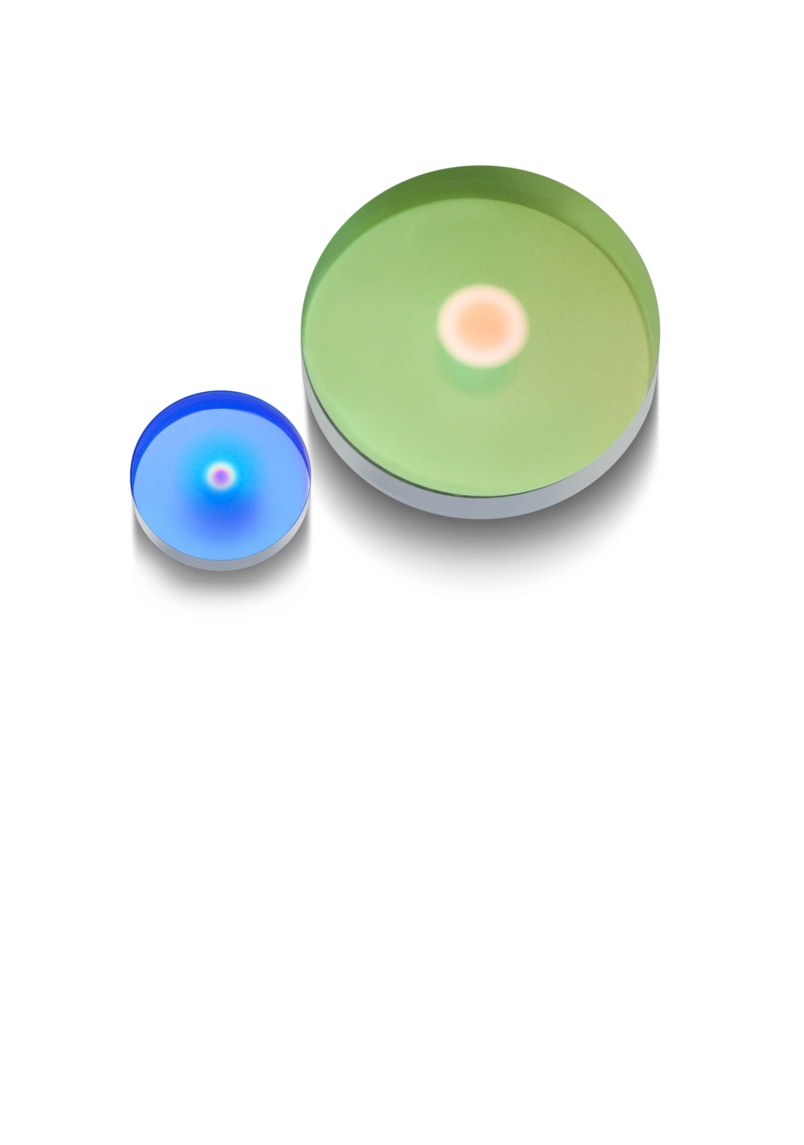

Fig. 4a and 4b show an example of a customized layering system. The mirror shown reflects the processing laser at 1 µm with over 99% efficiency, while at the same time transmitting more than 80% of the IR radiation and visible wavelengths for process monitoring. This is ideal for pyrometry, visual camera observation, and OCT systems.

By fine tuning the coating design, transmission and reflection can be optimally adapted to the desired application areas: High reflection minimizes energy losses in the processing beam, while high transmission in the diagnostic area enables precise temperature measurement and visual process control.

Quantum Nanolaminates

Future Trend

The development of optical coatings for high-performance material processing with lasers is a dynamic field. By combining advanced coating technologies, optimized process parameters, and innovative coating designs, optics can be produced that meet the increasing demands of the industry.

Quantum nanolaminates (QNLs), which are currently under development at LASER COMPONENTS, offer a promising approach to further increase performance. QNLs consist of a layer of very thin, highly-refractive and low-refractive alternating materials, with each layer being less than three nanometers thick. Due to this extremely low thickness compared to the wavelength of the light, the entire layer arrangement behaves optically like a single layer.

QNLs allow precise adaptation of optical properties to control the laser induced damaging threshold (LIDT). Initial investigations show that both the laser damage threshold and the spectral selectivity can be significantly improved with these systems, which could represent a decisive advance for compact or multifunctional laser optics in particular.

Product Overview

LASER COMPONENTS USA - Your competent partner for optical and optoelectronic components in the United States.

Welcome to LASER COMPONENTS USA, Inc., your expert for photonics components. Each product in our wide range of detectors, laser diodes, laser modules, optics, and more is worth every Dollar ($/USD). Our customized solutions cover all conceivable areas of application: from sensor technology to medical technology. You can reach us here:

116 South River Road

Building C

Bedford, NH 03110

USA

Phone: +1 603 821 7040

Email: info(at)