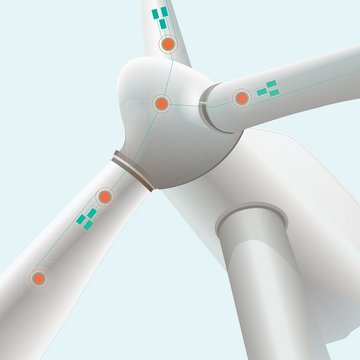

Fiber Technology Makes Intelligent Wind Turbines Possible

From Where the Wind Blows

Every year, approximately 25,000 new wind turbines are built worldwide – and the demand for this renewable energy source continues to increase.

The answer from manufacturers and wind farm operators has always been the same: they built larger and therefore more powerful turbines. On the other hand, the control technology for limiting and optimizing output has remained largely identical. At 170 m, the rotor diameters in offshore wind farms are now larger than the tower of the Ulm cathedral and thus at the limit of what is technically feasible. On average, even these huge wind turbines only achieve an efficiency of around 45 percent and run at reduced capacity far too often – for example, when the wind load is too high and could damage the wind turbine.

The Munich-based company fos4X GmbH optimizes the turbines using a combination of fiber measurement technology and artificial intelligence, thus increasing their efficiency. As a result, either considerably more power could be achieved even with smaller rotors or large but lighter rotors could be operated more load-efficiently and with less damage to the turbine.

Sensors in the Rotor Blade

Beyond Borders

The most important components in increasing the performance of a wind turbine are, besides the generator, the rotor blades. Their direction of inflow determines how efficiently the energy of the wind can be converted into electrical power.

Not only the general wind direction should be taken into account, which is the case in conventional turbines, but the orientation (i.e., the so-called pitch angle of the rotor blades) should also be adjusted to allow the wind energy to be used optimally as well.

Fiber-optic sensors inside the blades provide round-the-clock information about the physical properties of the rotor blade and the wind forces that strike it.

The Wavelength Shows the Force

Beyond Borders

For its measurements, fos4X uses industrialized edge filter systems in combination with fiber Bragg gratings (FBG). If broadband light is fed into the fiber, a certain wavelength is reflected by the grating.

This wavelength depends on the effective refractive index of the fiber core and the grating constant. If one of these factors changes due to external influences such as temperature fluctuations or expansion of the fiber, the Bragg wavelength also changes. This principle can be used in various sensors, for example, to measure the acceleration or elongation of the rotor blades in order to deduce the shear and torsional forces acting on the turbine at a given point in time.

With little cost and effort, these sensors can also be installed in existing turbines. In contrast to conventional electrical sensors, these sensors are insensitive to electromagnetic fields. This makes it possible to use these sensors at crucial measuring points in rotor blades despite the danger of lightning strikes. Furthermore, FBG application is considerably more robust than electrical sensor components that cannot cope with the enormous dynamic loads.

Intelligent Control Technology

Beyond Borders

Real added value is only created from the data recorded by the sensors through complex, self-learning algorithms. This digital technology transforms the wind turbine into an intelligent power generator based on the measured data.

For this purpose, an industrial PC – a so-called thin-edge client – is located in each turbine. In terms of Industry 4.0, the individual computers are linked with each other via the industrial internet of things (IIoT). This means that the wind farm operator always has an overview of the output and operating status of each individual turbine. At the same time, he can keep an eye on the values of the entire wind farm.

The collected data is continuously recorded and evaluated using artificial intelligence. The self-learning analysis software is increasingly capable of aligning the rotors of the individual wind turbines in such a way that the entire wind farm always delivers optimum performance. fos4X believes that this is the way to significantly increase efficiency in the wind energy industry.

At LASER COMPONENTS you can select the right fiber for your FBG-supported application in sensors, lasers, and spectrometers. In addition to fibers, in which one or more FBGs are already permanently inscribed, we also offer photosensitive fibers with various dopants. Customers with UV and femtosecond lasers can inscribe their own gratings.

Click here

LASER COMPONENTS France - Your competent partner for optical and optoelectronic components in France.

Welcome to LASER COMPONENTS S.A.S., your expert for photonics components. Each product in our wide range of detectors, laser diodes, laser modules, optics, fiber optics, and more is worth every Euro (€/EUR). Our customized solutions cover all conceivable areas of application: from sensor technology to medical technology. You can reach us here:

45 Bis Route des Gardes

92190 Meudon

France

Phone: +33 (0) 139 595 225

Email: serviceclient(at)