Optics | How to Clean Laser Optics

At high laser powers, even the smallest contamination can cause the laser beam to destroy the coating and thus the optics. At LASER COMPONENTS we therefore follow strict rules when cleaning. This is the only way we can ensure the high quality of our optics.

6 Steps to Clean Laser optics

Cleanliness is essential

1. Wear Gloves

Always wear gloves when handling laser optics!

Fingerprint residue cannot be completely removed even after just a short amount of time. If a fingerprint does get on the optics, it must be removed immediately as described below.

2. Blow it Off!

Never wipe off larger particles or impurities with a cloth. Depending on the particles, scratches may appear on the optics. Use a bellows or nitrogen instead.

3. Assessment

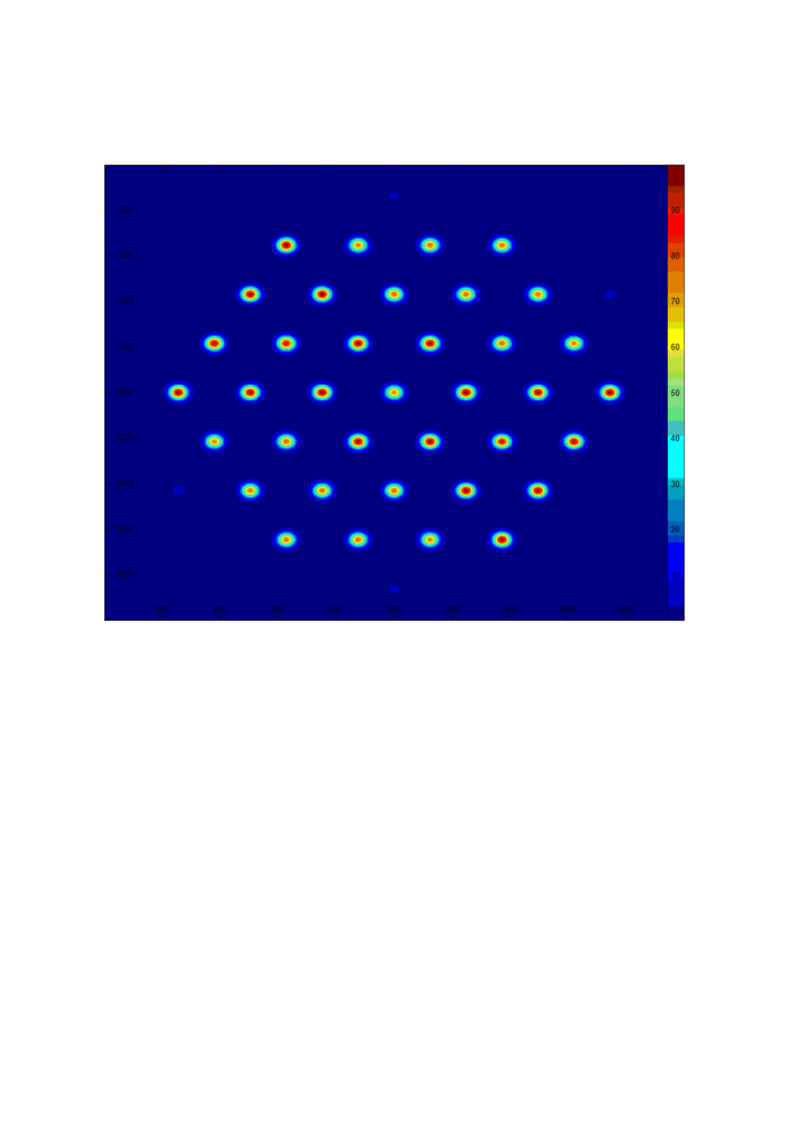

How to Check Your Optics. Check your optics carefully - if possible, in a darkened room. Inspection in transmitted light is best carried out using a clold light source. Errors and defects can also be easily detected in incident light at an angle.

Classify Size of Defects. During inspection, make sure that the environment is low in dust; this is the case, for example, with a laminar flow box. A measuring magnifier or a comparison template according to DIN-ISO 10110/7 will help you classify the size of defects.

4. Never Clean Metal Coatings

Metal coatings are incredibly soft. Even if the optics are easily wiped, you can damage the coating. So: Hands off!

5. Laser Optics Are Not Glasses

Eyeglass cleaning cloths often contain anti-fogging substances that are desposited on the optics and damage the coating. This lowers the laser damage threshold.

Only use pure actetone or isopropanol as a cleaning agent.

6. Observe Safety Instructions

Observe the standard safety regulations regarding cleaning agents. Read the safety datasheets carefully. Use solvent-resistant gloves and ensure that your working area is well ventilated.

+33 179858604

See Now How it Works

Use acetone- or isopropano-resistant cleaning cloths such as, for expample, Whatman paper.

As soon as the cleaning cloth begins to fuzz, it should be replaced with a new one.

Fold a cloth so that the surface is as flat as possible, and the cloth can be held in a self-clamping tweezer. Please make sure that no parts of the tweezers protrude over the cloths; otherwise you will scratch your optics.

Now slightly moisten the cloth with acetone or isopropanol. You must experiment a little bit to find the optimal amount. Too much solvent will leave streaks; too little will cause the cloth to fuzz faster.

It is best to clean the optics in circular movements. Start in the middle and work your way to the angle. Make sure that you exert constant presssure that is not too little on the surface using the cloth.

Contact us for further Information

Laser Optics

manufactured by LASER COMPONENTS

Explore Our Product Portfolio

We will be there for you

LASER COMPONENTS France - Your competent partner for optical and optoelectronic components in France.

Welcome to LASER COMPONENTS S.A.S., your expert for photonics components. Each product in our wide range of detectors, laser diodes, laser modules, optics, fiber optics, and more is worth every Euro (€/EUR). Our customized solutions cover all conceivable areas of application: from sensor technology to medical technology. You can reach us here:

45 Bis Route des Gardes

92190 Meudon

France

Phone: +33 (0) 139 595 225

Email: serviceclient(at)