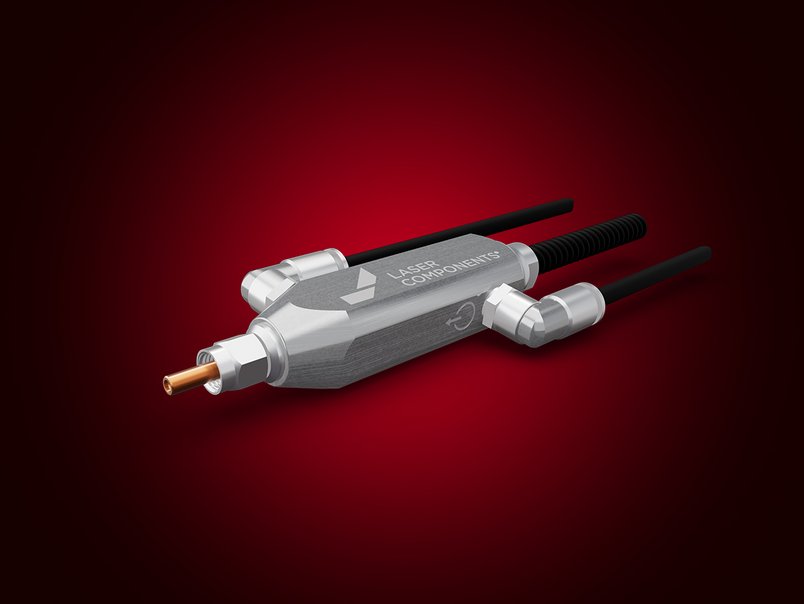

When fulfilling customer requests in fiber optics, LASER COMPONENTS’ production department works closely with the company’s cross-disciplinary R&D team. This has the advantage that the fiber engineers also benefit from the experience gained by other departments such as thin-film technology and electrical engineering.

Thanks to this exchange of experience at the Olching site and investments in modern production equipment, LASER COMPONENTS is in a position to provide fiber ends with different, customized “fiber tips.” In this way, the properties of the transmitted light can be optimized or modified according to customer requirements.

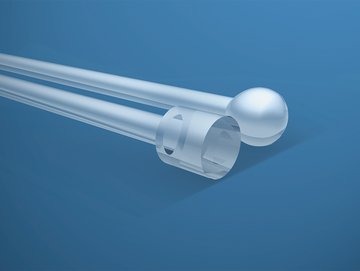

Shaped fibers include spherical lenses for medical applications. The fiber end, which is shaped into a sphere, collimates the outgoing beam and at the same time significantly reduces the risk of injury inside the body.

End caps increase the damage threshold of the fiber when coupling high optical power. They prevent the fiber from being destroyed under the high-power density. The beam properties remain unchanged.

Tapers are fiber ends in which the diameter is tapered by drawing the fiber. The size ratio between the core and cladding diameter remains unchanged. This results in the beam leaving the fiber with a larger beam angle.

“Our fiber tips are individually manufactured according to customer specifications and can also be equipped with anti-reflective coatings upon request,” explains Dr. Stefan Hanf, fiber optics production manager at LASER COMPONENTS. “Of course, we are also always ready to find innovative solutions for extraordinary requirements together with our R&D team.”