Determining the Exact

Laser Module for

Machine Vision Applications

Selecting a laser module to fit an application should be a fluid process. From identifying key specifications to considering unique variables and requirements to testing and potentially customizing the final laser – it is not a one-size-fits-all solution.

Many off-the-shelf laser modules will suit more common applications; however, three key factors will impact the precision, performance, and durability of the laser module within a system.

We will discuss those key factors, outline the standard specifications of the laser itself and provide guidance on when customizing a laser module could be the best solution.

System Parameters, Process Goals

and their Impact on Precision

/ Technology

Matching the best laser specifications to an application starts by considering the type of technology applied. Each type of technology applied in Machine Vision – displacement, measuring width and length; profile, measuring the outline or 2-D shape of an object; and snapshot, measuring various points on an object to generate a 3-D image – will require a different beam profile to best measure and produce an image rendering.

/ Object size and material

The size and material of the object(s) being measured must be considered to select the optimal combination of wavelength, line width, and depth of focus. The wrong wavelength for the color and material of the object being measured will result in limited visibility or too much refraction of the laser light to generate accurate measurements. Too fine a line width will result in highly inaccurate measurements if a greater depth of focus is required. Line width and depth of focus are generally related by a factor of 1.4.

/ Working Distance

Depth of focus is a physical parameter that measures how quickly a line will go out of focus and become thicker as the object moves out of the focus distance. In some cases, it is not always possible to measure objects directly in the focus position, but it may be necessary to move a few millimeters out of that focus position. If the line gets very thick very quickly outside of that focus position, it will be impossible to get an accurate measurement. A higher depth of focus ensures that while the laser may not be in its ideal focus distance, the line thickness is still acceptable for performing the task at hand.

Operating Environment

and the Impact on Performance

Changing temperatures, exposure to air, and other variables of the operating environment will impact the performance of the laser. As such, operating conditions should be a primary consideration. For example, a highly controlled laboratory environment could allow for the use of a laser outside of the eye-safe classification.

When operating in an outdoor environment subject to varying light levels, wide ranges of temperature, dust or debris, and other variables, selecting the right output power along with the correct housing size and material will also be critical.

Key considerations of an operating environment are:

- Laser exposure to water, moisture, etc.

- Laser exposure to the elements

- Varying temperatures

- Other objects coming into contact with the laser

- People in proximity to the laser when in operation

Laser Module Location

and available Space for optimal Durability

The space available for the laser module within the machine vision system is another component critical to the successful operation of the laser. The durability of the laser, precise measurements and optimal performance all rely on how securely the housing sits within a system and how durable the housing material is in regard to the operating environment. A laser module’s housing can easily be customized, and there are several variables to consider when determining the material, size, and form factor of a laser module housing.

Key considerations include:

- Standalone module

- Integrated module

- Exposure of housing to extreme conditions

- Size of available space for the module

- Additional connections to the module

In a standalone system, the size of the laser module is likely not limited by fitting into an existing system, and there is much greater flexibility regarding the size of the housing. Very often, an off-the-shelf module will suit the application with no risk to durability, precision, or performance.

For systems that integrate a laser module, requiring a fixed size, the accurate integration of the laser module within a specific system will ensure stability of the module - protecting it from vibrations and preventing movement of the module.

Another housing factor is the environment in which the laser will be used, and certain housing materials will ensure greater durability and longevity of the module over time vs. a standard housing. Will the device be exposed to harsh environmental conditions such as extreme temperatures, moisture, or more? For these applications, the housing will need to be IP54 or IP67 protection class rating.

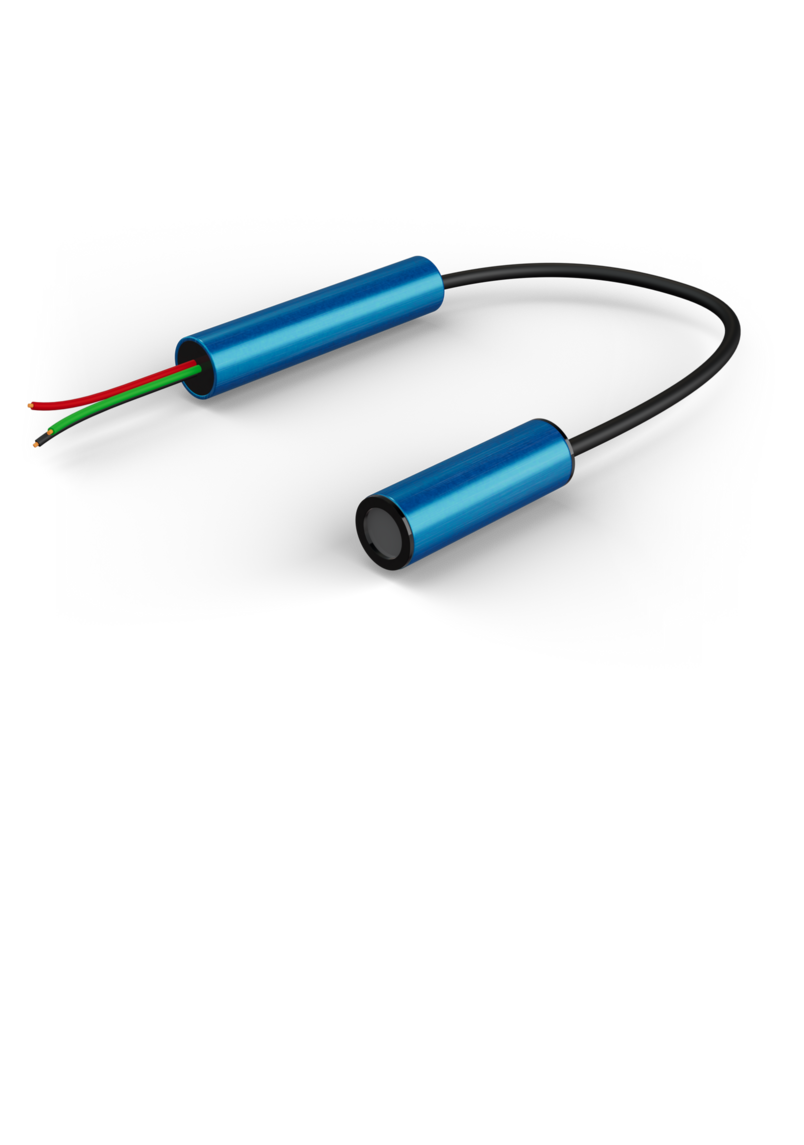

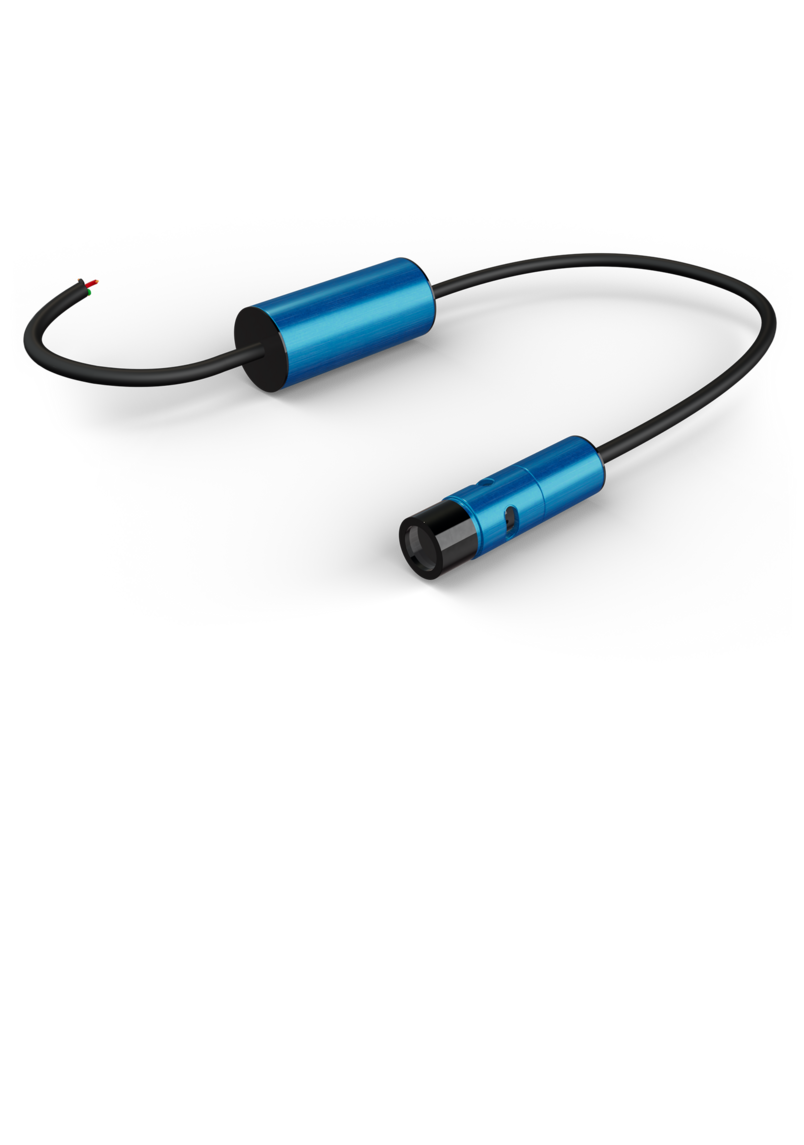

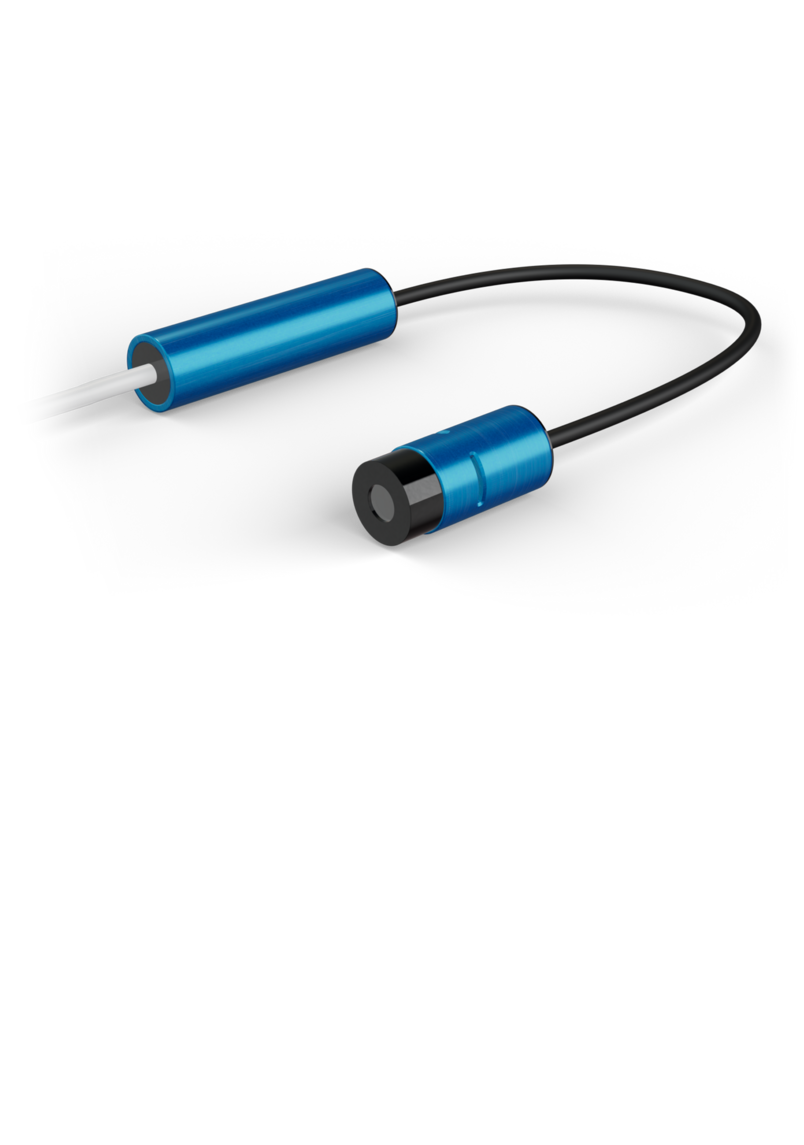

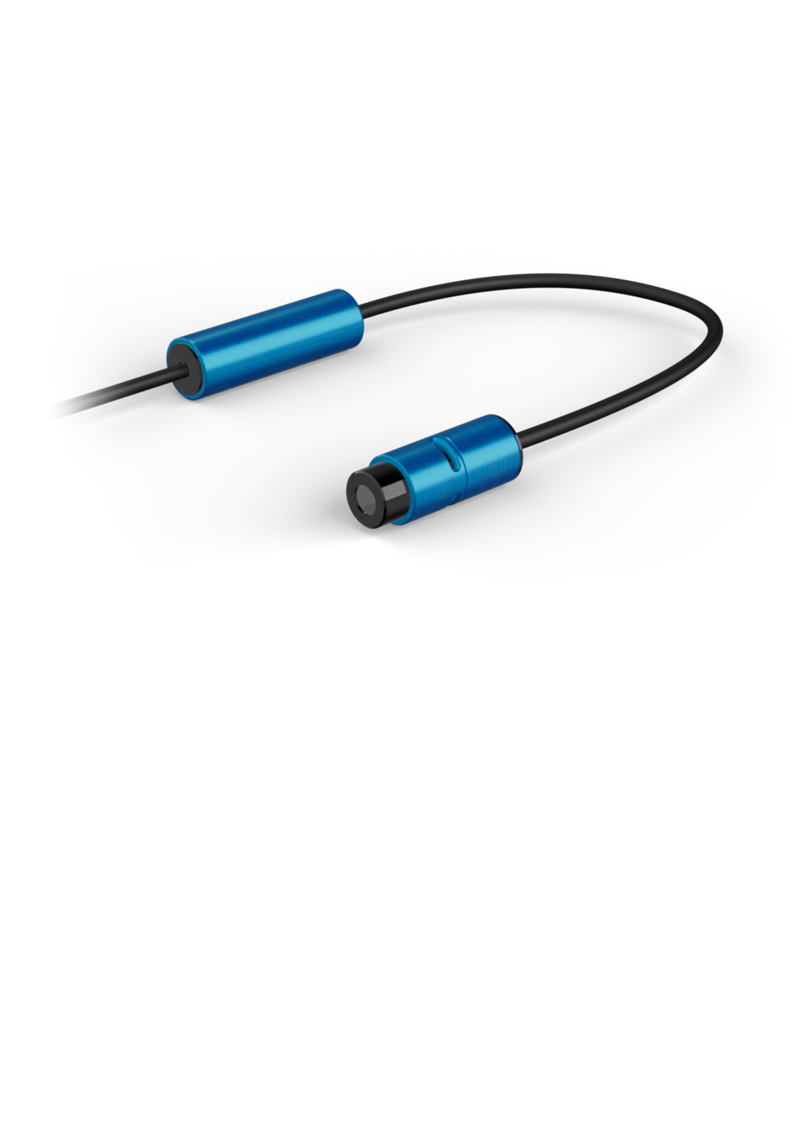

Certain types of integrated laser module applications may require a two-housing configuration by which the optics are installed in one housing and the drive electronics are installed in the second. This offers greater flexibility and can deliver advantages in situations where heat and wavelength drift may be issues.

Click here

Laser Module Specifications and Available Ranges

from LASER COMPONENTS

/ Line Width

Standard, thin and enhanced lines are available. Use our custom line width simulator to determine the optimal line width, power, and wavelength combination based on the required working distance. Line widths as fine as 10 microns are available up to several 100 microns.

/ Wavelength

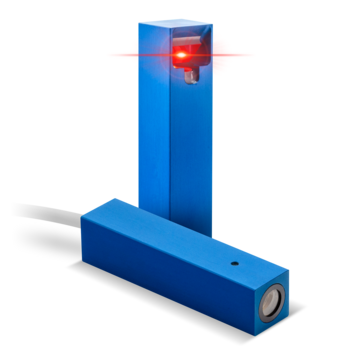

Ranging from 405–850 nm, choosing the right wavelength is dependent on the color and type of material the laser is projected onto, as well as the sensitivity of the camera.

/ Power Output

10–100 mW. Often, a pulsed laser can accomplish the same process requirements of a higher powered laser while operating at class 2 eye safety.

/ Beam Profile

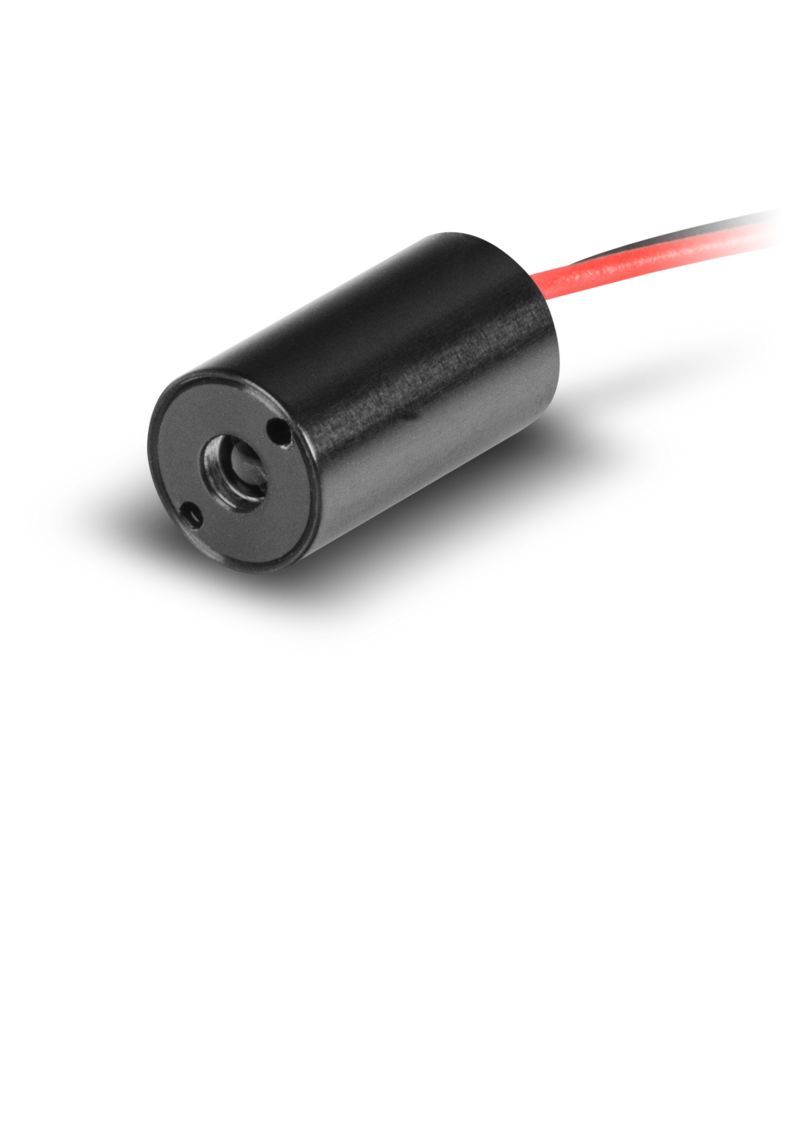

Dot, line or pattern. With 30+ patterns available and able to be installed as fixed within the module or as a removable cap.

/ Housing

Standard housings are available as small as 8 mm in diameter and 16 mm in length. Select laser modules housings will meet protection class IP67 requirements. Because LASER COMPONENTS manufactures every FLEXPOINT® laser module in-house, there are a variety of options to customize the size and material of the housing, as well as offer dual housing modules.

/ Modulation Frequency

If the laser is required to turn off and on in accordance with the system, the modulation frequency can be specifically programmed.

When a Custom Laser is the Best Fit

Many readily available laser modules will suit the majority of applications. When considering the specific requirements of a single, unique application - if the thought of compromising durability for performance, or risking precision for lack of proper housing arises - it is time to search for a supplier able to offer more options. It can be difficult to identify each of the parameters listed above on paper, and this is where a trusted partner comes in vs. purchasing an out-of-the-box solution.

The variety of offerings combined with full ownership of the manufacturing process allows LASER COMPONENTS to combine a wide array of variables into a custom-built laser for each specific application.

At LASER COMPONENTS we offer a wide range of specifications, manufacture 100 percent of our FLEXPOINT® Laser Modules in-house and every sales member has direct experience in technical and design engineering to consult on any project.

LASER COMPONENTS Germany GmbH