Production of High-Power Fibers

The transmission of high optical power via fiber optics always poses a challenge. One of the main dangers is cladding modes. Especially in high-power systems, they can quickly lead to overheating in the adhesive, connector system, or fiber, and subsequently destroy the fiber. LASER COMPONENTS’ ModeStrip process provides a remedy.

Burning Cladding Modes

Beyond Borders

In many industrial applications, companies are increasingly relying on fiber-coupled diode laser systems. The welding of sheet metal and plastics, the soldering of electronic components, and the hardening of steel are just a few examples. These devices deliver the desired quality at high power and require very little space. In addition, the laser beam can be flexibly directed to any location with the fiber. The central wavelengths are usually 808 nm or 980 nm. Depending on the fiber cross-section, LASER COMPONENTS supports cw laser power in a range from 35 W to 400 W.

As always, in addition to the advantages mentioned, there are also risks that must be taken into consideration. The most critical area is the interface between the laser and the fiber. The highest precision is required when coupling light. As a rule of thumb, the beam diameter should not be larger than 80% of the fiber core during coupling: The thinner the fiber, the more complex coupling becomes. At the same time, the divergence angle of the beam must be smaller than the numerical aperture of the fiber. This is especially important when the laser is operated at the upper limits of its power capabilities because then the divergence increases and there is a risk of over-radiating the fiber core.

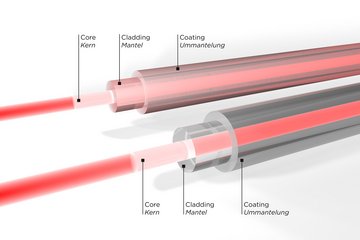

Light that has not been coupled into the core but rather into the surrounding cladding is transmitted as so-called cladding modes. This not only means a loss in performance but also involves great risk. The cladding modes are not dissipated at the end of transmission like the rest of the transmitted light. They remain “trapped” in the fiber cladding (see figure 3). Their power is released as heat and can cause considerable damage. For example, it is possible for the adhesive of the connector system to heat up or for the fiber to literally burn off, making it unusable afterwards.

Picture: ModeStrip with an SMA connector

Protection through Precision and Technology

Beyond Borders

To ensure that cladding modes do not cause any damage, several measures are taken when the fibers are assembled. Care is initially taken to ensure that the fiber is positioned as centrally as possible in the connector at both ends to optimally couple the laser beam and prevent cladding modes from occurring. This is particularly important if the beam is not manually adjusted during coupling, as is often the case with larger systems. Although manual alignment is time-consuming, it is usually performed with the highest precision. Assemblies from LASER COMPONENTS are optimally aligned so that they can be easily exchanged according to the plug-and-play principle.Specialized companies such as LASER COMPONENTS achieve centricity values for the alignment of fiber assemblies where the deviation of the fiber center to the ferrule is less than 5 µm. Nevertheless, something can always “go wrong” – especially with unfavorable beam profiles.

The resulting cladding modes can be removed using cladding mode strippers such as LASER COMPONENTS’ ModeStrip. In this process, the fibers are processed to allow the light to escape from the cladding shortly after it is transmitted. It is dissipated into a heat sink integrated in the connector and can no longer cause any damage during decoupling.In addition to laser coupling, mechanical design plays a crucial role in fiber assemblies for industrial applications. In daily operation, the cables are subjected to heavy stress, and mechanical damage to the fiber, such as bending too tightly, can also lead to the development of cladding modes. In movable systems, for example, both a robust connector design and the use of steel reinforcements in the protective sheathing ensure the desired drag chain suitability.

Picture: Overshot fiber core (rear), optimal beam coupling (front)

Individual Fiber Solutions

Beyond Borders

When assembling fiber optic cables, LASER COMPONENTS specializes in custom solutions. For quality assurance, the production area has extensive testing facilities. Upon request, transmission properties, end face quality, centricity, and numerical aperture can be documented. For special requirements, our in-house R&D team develops innovative solutions such as individual coatings for fiber end faces and end caps.

Downloads

Beyond Borders

LASER COMPONENTS UK - Your competent partner for optical and optoelectronic components in the United Kingdom.

Welcome to LASER COMPONENTS UK Ltd., your expert for photonics components. Each product in our wide range of detectors, laser diodes, laser modules, optics, fiber optics, and more is worth every Pound (£/GBP). Our customized solutions cover all conceivable areas of application: from sensor technology to medical technology. You can reach us here:

Goldlay House, 114 Parkway

Chelmsford Essex CM2 7PR

United Kingdom

Phone: +44 1245 491 499

Email: info(at)