LASER COMPONENTS Germany - Fiber Optics

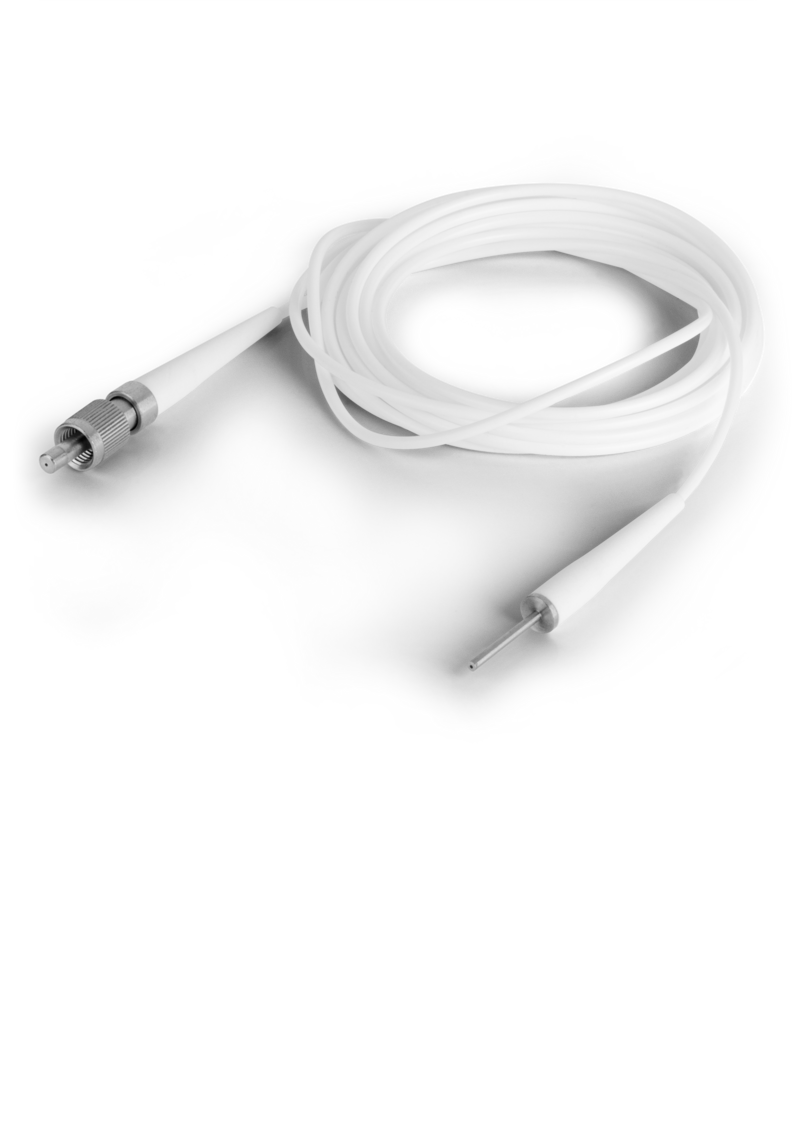

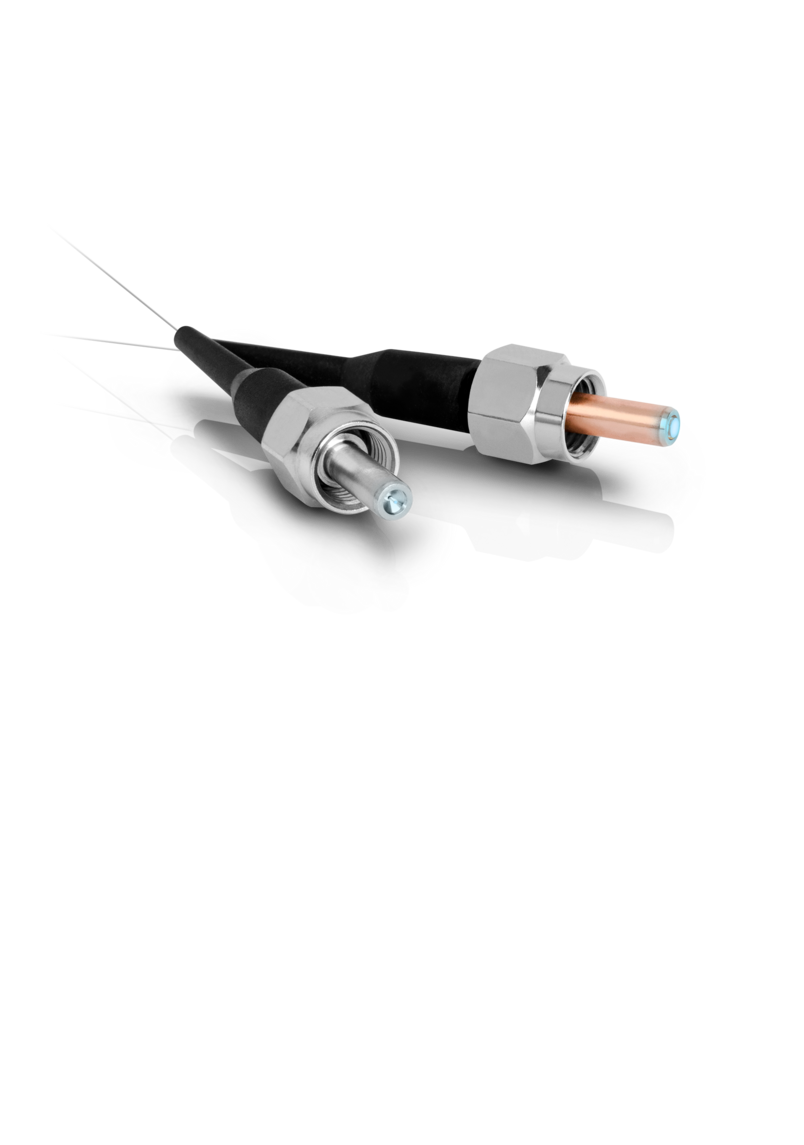

Fiber Connector Assemblies

Assembled Fiber Optics

Based on the needs of our customers for more flexibility and faster availability we began developing and manufacturing assembled fiber optics in 1995.

Since that time, the range of available fiber / connector combinations has grown steadily and a large volume production has ensued. The range of assembled fibers stretches from large core HCS fibers starting at 100 µm to >1500 µm. Graded index fibers that have a core diameter of 50 µm, 62.5 µm, and 100 µm can also be assembled according to customer specifications.

Special products such as sterile patch cords, high power SMA connectors with free-standing fibers, and light bundles made from POFs have stemmed from the developments made in recent years. Specialty customer-specific solutions for use in medicine, laser systems, sensor technology, the automotive industry, and industrial applications are the main focus here. Take the opportunity to talk directly to the manufacturer about your application.

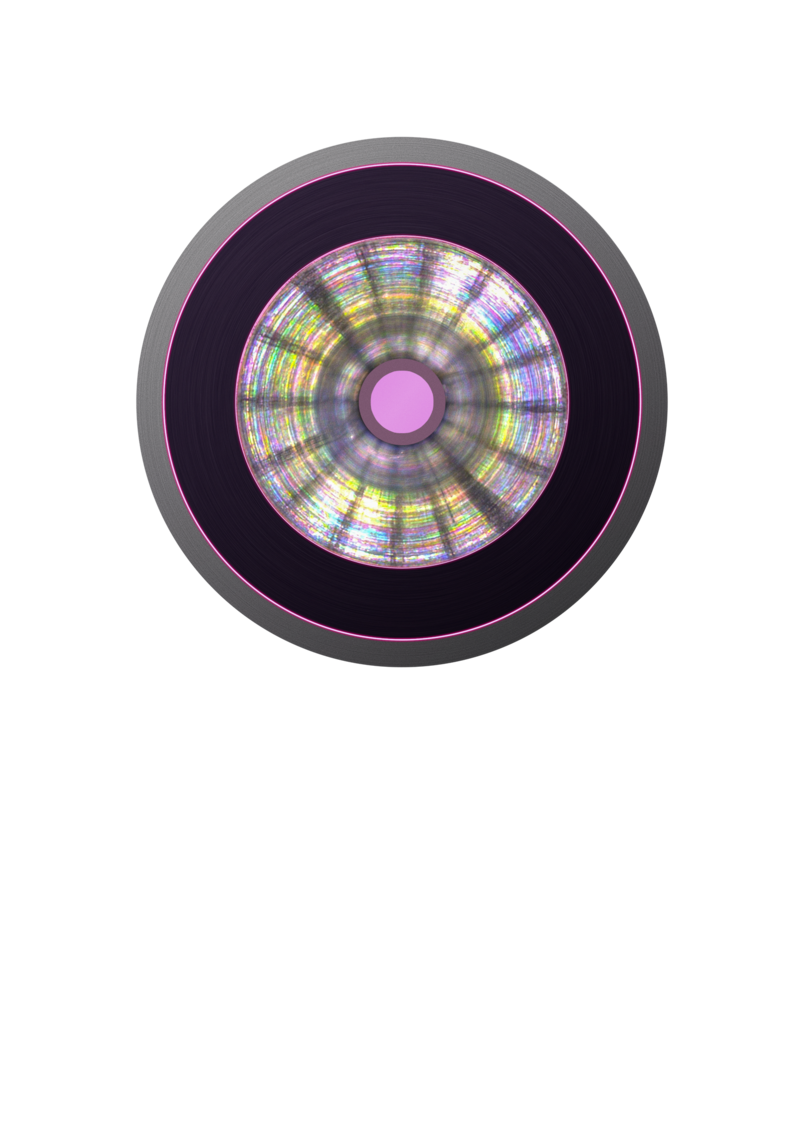

Coated Fibers

Fiber tips with AR coatings reduce coupling losses. At LASER COMPONENTS GmbH different coatings can be applied, such as, for example&%2358;

Single AR coatings for a single wavelength (e.g. 808 nm)

Dual AR coatings for two wavelengths (e.g. 808 nm and 980 nm)

Broadband AR coatings for a wavelength range (e.g. 460-700 nm)

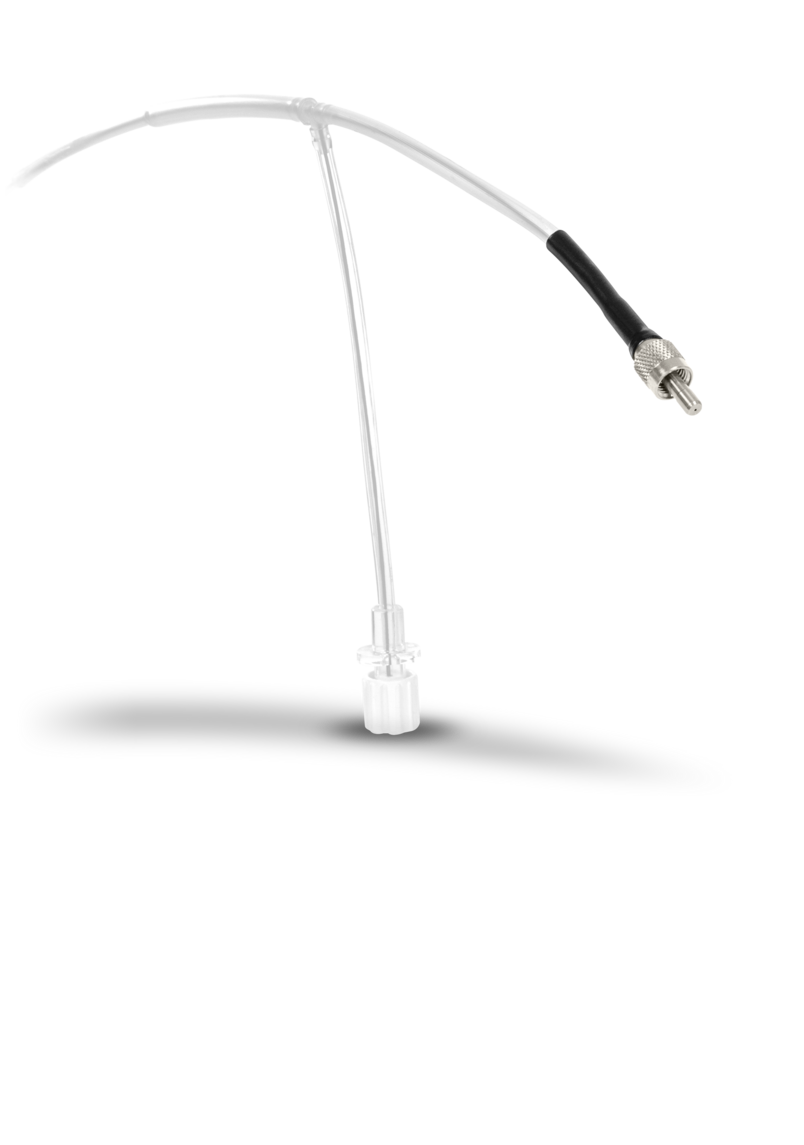

MediStrip – Sterilizable Fiber Stripper

In medical applications that require optical fibers it is becoming more and more common to have to prepare the fiber again during an operation. For this purpose, the MediStrip, a sterilizable fiber stripper, was developed. Methods of cleaning and sterilizing were validated by an independent test laboratory.

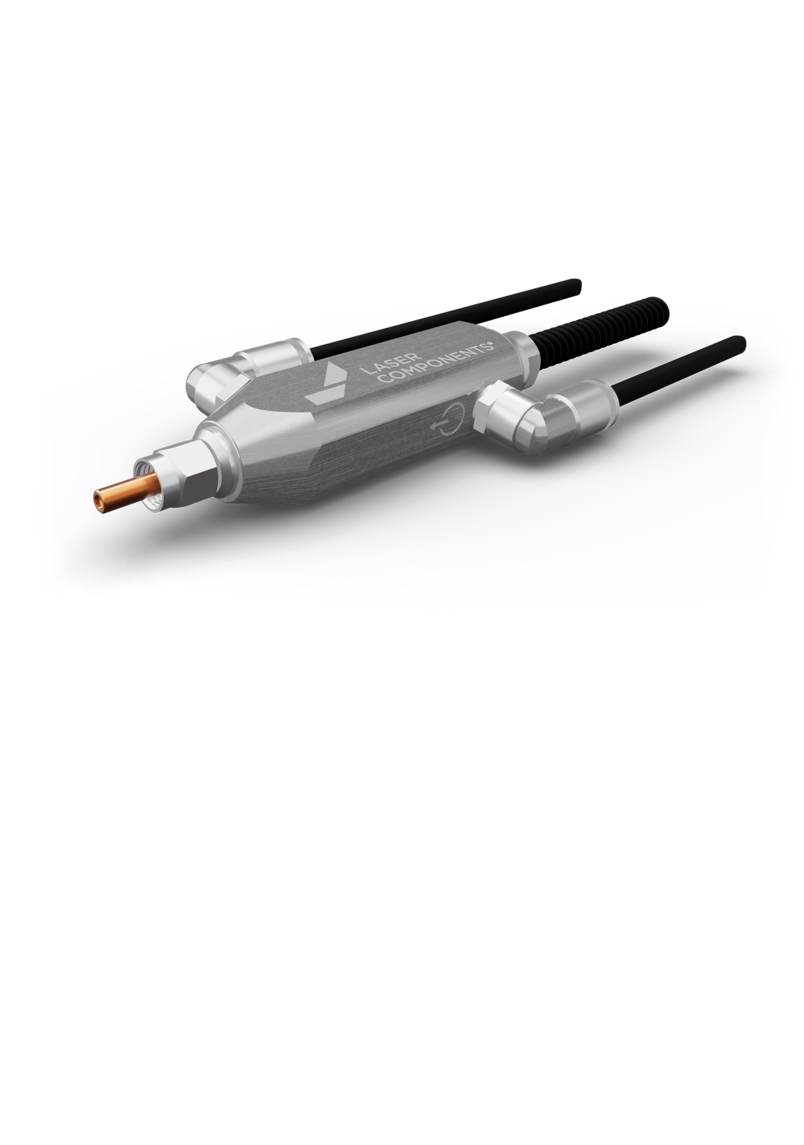

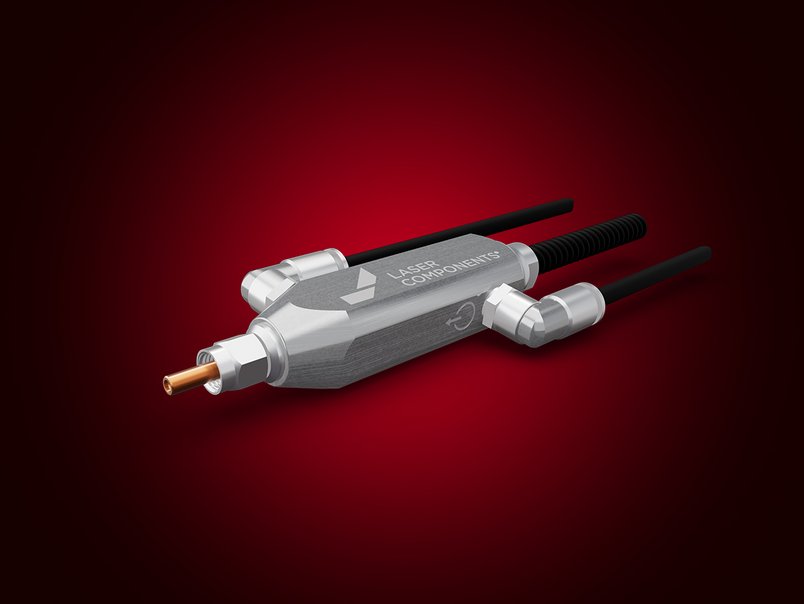

Crimp & Cleave

Our fiber group performs all repair and calibration tasks related to the tools used in crimp & cleave technology.

Laser Modules

Our module production facility saves as both a site for design and development as well as a reliable site for small and large series production. Thousands of laser modules of our FLEXPOINT® trademark are being produced in various designs annually.

FLEXPOINT® laser modules consist of a cw laser diode (405-905 nm) or a DPSS (diode pumped solid state) module (532 nm), application-specific optics (dot, line, crosshair, or DOE optics), electronics, and a potential-free housing. Different wavelengths and power levels as well as different drivers with digital or analog modulation increase the flexibility of the miniature laser system. Only electronics that have been developed by us are used in the modules. All FLEXPOINT® laser modules are CE certified and conform to RoHS standards. The laser class of each module is specified according to DIN EN 60825-1.

In addition to the latest developmental tools for optical design and beam profiling, we use a 3D CAD system is being used that can simulate an entire laser module in the preliminary stages of development, which saves time and money on expensive and time-consuming “trial-and-error” phases. Small mechanical tasks can be performed directly at the attached workshop. LASER COMPONENTS offers its customers the option of developing a custom laser module that is suited directly to their application and then produce it in series. We will accompany you every step of the way – from the idea to series production – never losing sight of our premise to always offer the customer the module that is best suited for the application at hand.

Photon Counter

In 2010, LASER COMPONENTS introduced yet another innovative product into the market&%2358; complete single photon counting modules. Laser Components successfully met the demands of its customers for a high quantum efficiency and very low dark count rates with these modules.At the heart of the COUNT modules is a Geiger-mode silicon avalanche photodiode, which was specifically developed by the LASER COMPONENTS Detector Group. This APD is one of the lowest-noise photodiodes on the market and features an excellent quantum efficiency in the blue and red spectral regions.

Both the production facility and testing laboratories for inspection, measurement, and qualification of the COUNT modules are located in Olching (Germany).

Optics

Since 1986, the name LASER COMPONENTS has stood for top quality optics for laser technologies. Well-known laser manufacturers count on our optics, which cover the complete spectral range from 193 nm (UV) to 3.2 µm (MIR).Technologies

Inside our specially-developed, high-vacuum chambers containing an electron beam gun, we coat both our own as well as substrates supplied by customers with diameters ranging from 4 mm up to 390 mm.

Rush jobs can be done within 24 hours upon request.

The optics manufacturing department has six coaters. Two of these coaters uses sputter technology which allows us to manufacture even better optics for the next generation of lasers.

Our specialties include the manufacture of glass parabolic mirrors for thin disk lasers, adaptive optics, and Gaussian mirrors.

LC Electronics

To meet customer specifications quickly and flexibly, LASER COMPONENTS opened its own electronics production facility. At this facility, circuit boards are designed to drive PLDs and APDs. We also manufacture prototypes before they go into series production. Another major field is the individual production of customer-specific products!

Production Steps

Our customers state their electronics requirements, and our R&D engineers create an appropriate CAD design. This software directly controls the circuit board milling machine for the production of prototypes. Electronic components are applied manually during this developmental stage. The results of a comprehensive inspection of these prototypes determine whether they proceed to series production.

PLD Modules

One example of a series product is our PLD modules. With these modules pulsed laser diodes can be operated safely, resulting in an optimal and thus reliable driver. The PLD is already integrated into the module. One unique product is our adjustable modules, which allow the continuous adjustment of both the output power and pulse length. They are particularly well suited for product R&D to test the ideal settings.

High Voltage Modules for the Operation of APDs

Temperature-stabilized high voltage modules are particularly well suited for the operation of Avalanche photodiodes (APDs). Output voltage and temperature compensation can both be matched exactly to the APD being used. Connecting the module and the APD is simple, and can be done with the help of the supplied diagram.

APD Modules

The APD modules are based on low-noise avalanche photodiodes made of either silicon or InGaAs with a built-in pre-amplifier and high voltage supply. A temperature compensation function allows the APD to be operated at constant gain across a wide operating temperature range.

Click here

Products

News

LASER COMPONENTS USA - Your competent partner for optical and optoelectronic components in the United States.

Welcome to LASER COMPONENTS USA, Inc., your expert for photonics components. Each product in our wide range of detectors, laser diodes, laser modules, optics, and more is worth every Dollar ($/USD). Our customized solutions cover all conceivable areas of application: from sensor technology to medical technology. You can reach us here:

116 South River Road

Building C

Bedford, NH 03110

USA

Phone: +1 603 821 7040

Email: info(at)