PbS detectors exhibit a higher sensitivity than PbSe detectors, by more than one order of magnitude; however, the time constant is longer. The IV-VI semiconductor PbS is a photodetector that reacts to incident IR radiation and changes its electrical resistance.

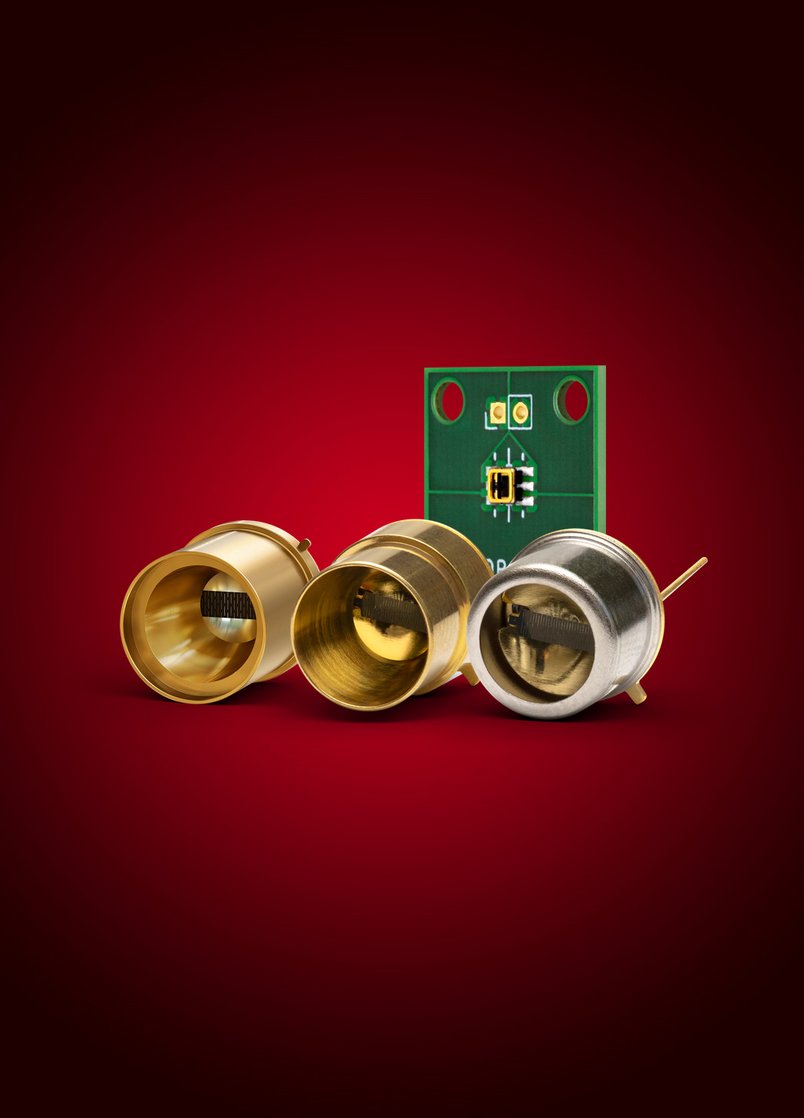

These detectors are used especially when large-area detectors are required because they are significantly less expensive than comparable InGaAs detectors. The typical chip size of LASER COMPONENTS’ standard detectors is 2 mm x 2 mm. Other configurations are also available upon request.

Application Fields:

The fields of application are manifold, examples of which include:

- Temperature sensors – pyrometers

- Flame and spark detectors

- Moisture sensors

- Measurement of coatings and oil films

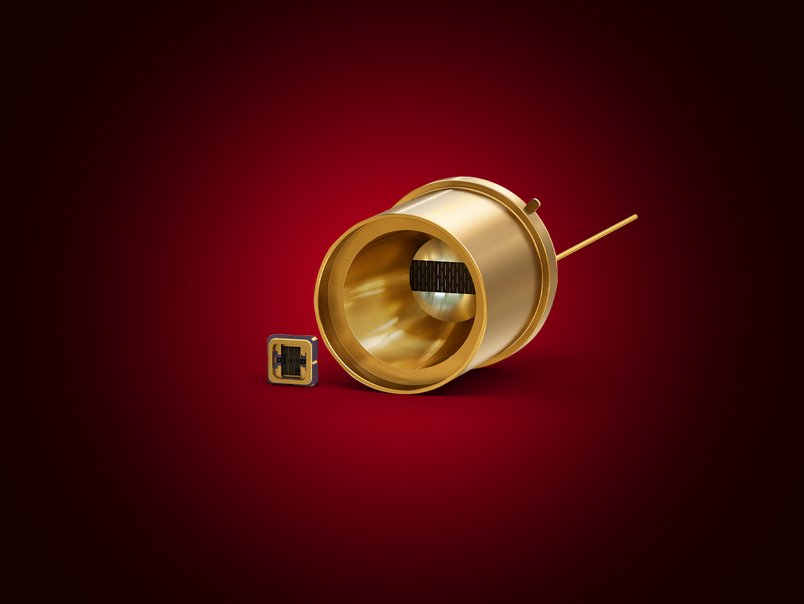

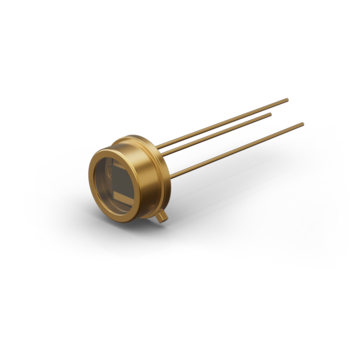

PB25/27/30 – LASER COMPONENTS’ PbS Detectors

The standard size of detector elements in our lead sulfide series is 2 mm x 2 mm. Other sizes, as well as elements with Peltier cooling, are also available upon request.

Compared to InGaAs detectors, PbS elements, especially large-area designs, are available at a lower price and are thus still relevant.

Contact

Detector Search

Find the right detector and the respective data sheet in just a few clicks.

Datasheets

RoHS Information

Our IR Detectors

Panchromatic, photoconductive and thermal detectors

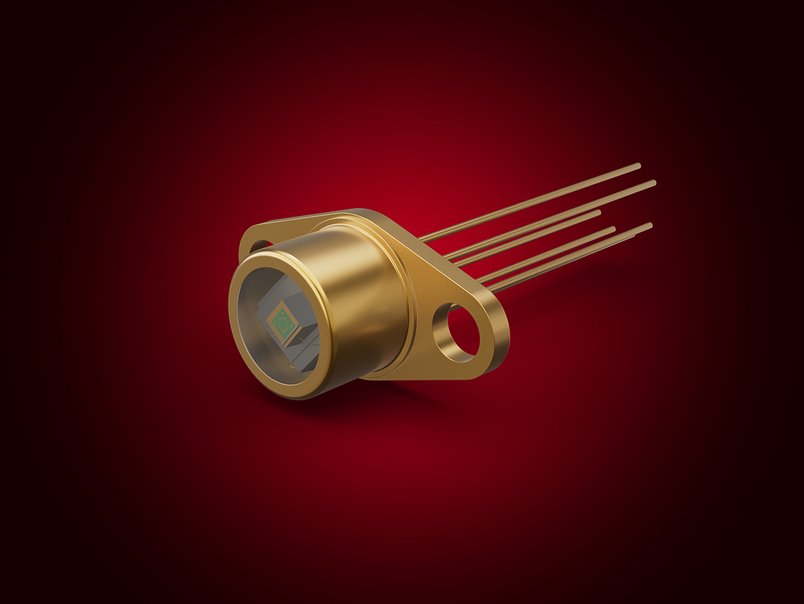

InGaAs PIN Photodiodes

Modern InGaAs PIN photodiodes are panchromatic and convert broadband light to photocurrents in the Visible-NIR range. Concretely speaking, this means a sensitivity range from 500 nm to 1700 nm for regular InGaAs and – in increments – up to 2600 nm for extended InGaAs.

PbS and PbSe Detectors

PbS is a standard Short-Wave Infrared (SWIR) semiconductor detector (1 - 3.3 µm) whereas PbSe is used in the Mid-Wave Infrared (MWIR) range (1 - 4.7 µm when uncooled; up to 5.2 µm when cooled). Our PbS and PbSe detectors are photoconductive; the detector resistance is reduced during illumination. The crystal structure is polycrystalline and is produced via chemical deposition.

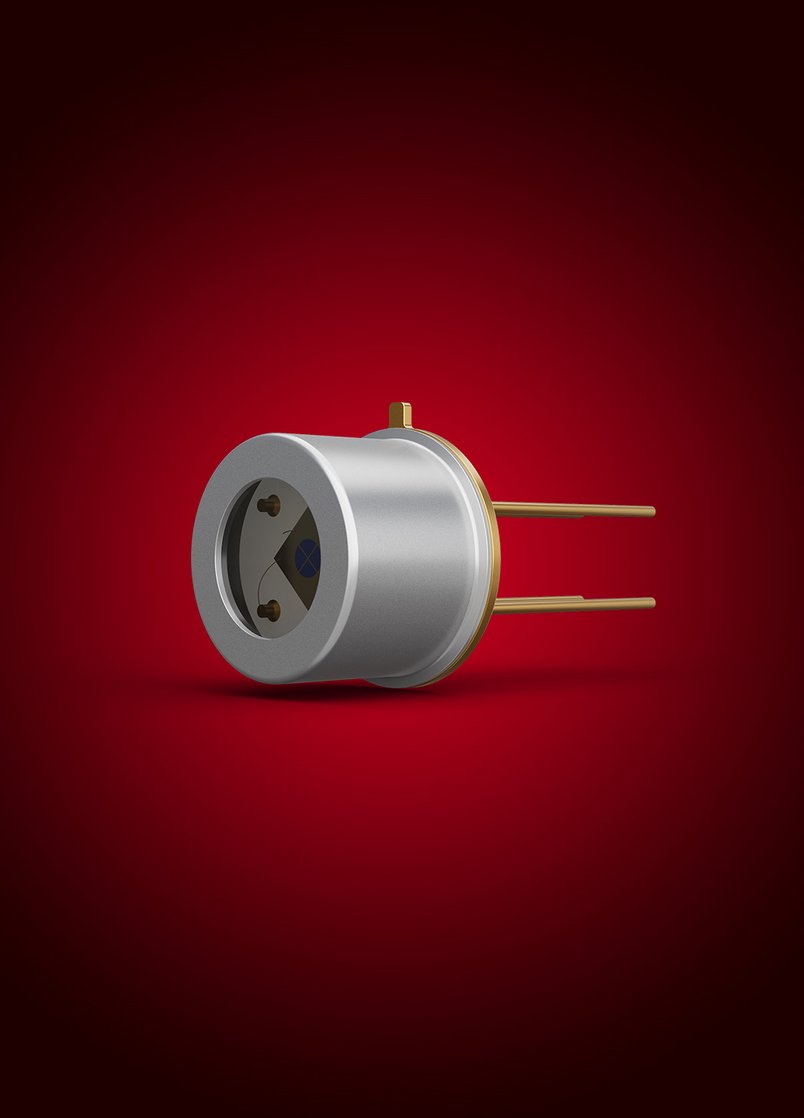

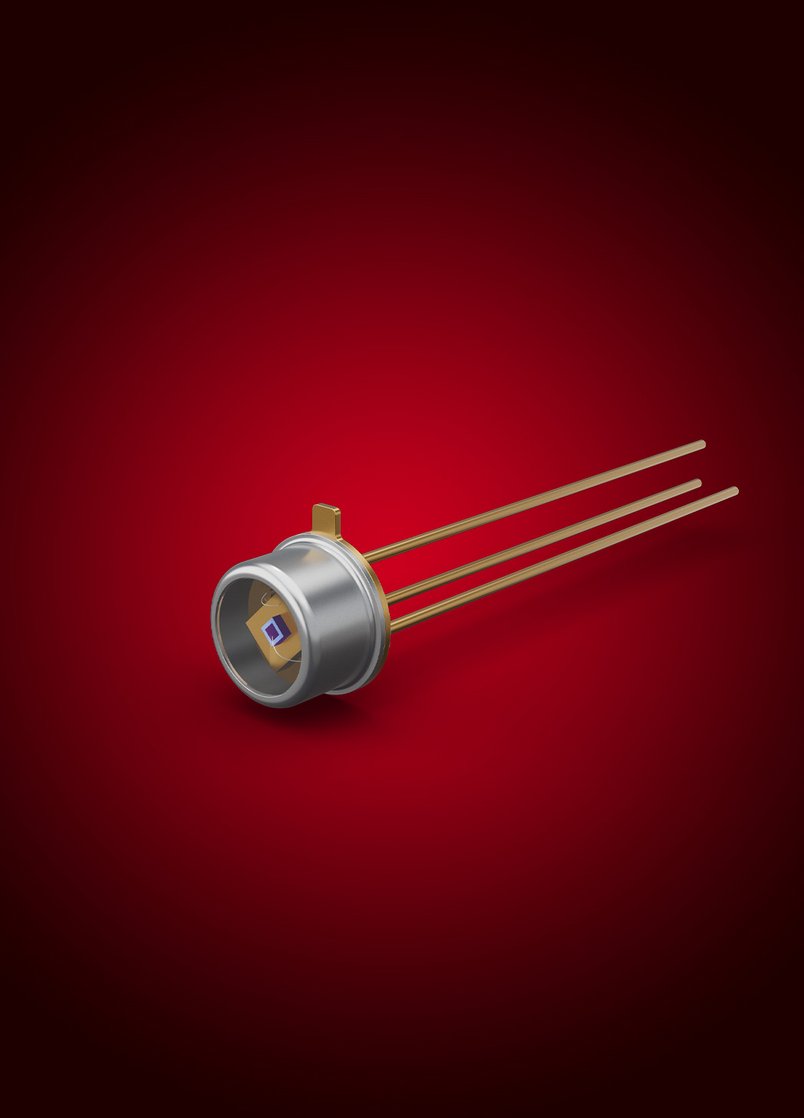

Pyroelectric IR Detectors

A pyroelectric IR detector is a thermal detector in that it responds to the change in heat (IR) absorbed on its surface. Thermal detectors are polychromatic with a very wide spectral bandwidth.

The nature of the pyroelectric effect is that in a highly-ordered crystal (or ceramic), a temperature change in the element causes its atoms to move slightly out of position. This rearranges its electrical charge, which is measured in the electrodes on its surface.

The pyroelectric effect is found in many materials. The most commonly-used materials are deuterated lanthanum α alanine-doped triglycine sulfate (DLaTGS) and lithium tantalate (LTO).

Detector Selector

Find the right Detector with just a few clicks

What is Your Challenge?

Beyond Borders

LASER COMPONENTS Germany GmbH

News & Events

from the infrared world