Technologies

AT LASER COMPONENTS

The central R&D department is an independent division at LASER COMPONENTS. We have access to vastly different technologies, the combination of which can lead to novel products and even trigger new business fields.

We can take over an entire R&D project for our customers with our team. Inquire with us about it!

Semiconductor Technologies

Beyond Borders

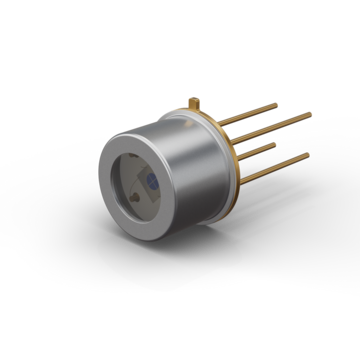

Assembly technology is one of our core competencies. To produce different detectors in the wavelength range between 210 nm and 100 µm, we primarily use the following materials:

- Si

- InGaAs + extended InGaAs

- InAs

- PbS

- PbSe

- DLaTGS

- LiTaO3

For the emitters, however, the following is used:

- AlGaAs

- InGaAsP

- GaA

Dielectrical Coatings

Beyond Borders

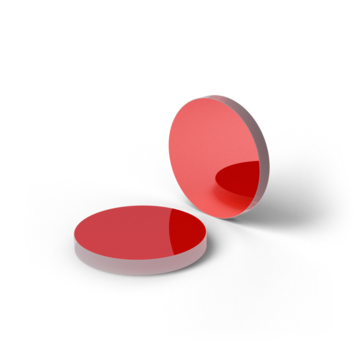

High-Power Laser Optics

Mirrors, retardation plates, and polarizers: These products often have identical substrates – the difference lies in the coatings. Thin layers of solid substances are applied to the glass body; these layers often change the characteristics of the final product – mostly due to the interference effects. Depending on the coatings, sometimes two and sometimes more than one hundred layers are applied on top of each other. Depending on the material, the layer thicknesses are between 31 nm and 400 nm.

The art of creating optimal laser optics lies in the combination of different layer thicknesses and materials with different refraction indices. Calculations that are more or less easy to carry out in theory sometimes lead to unforeseen challenges in practice because there is one thing that a coating is definitely not allowed to do: it is not allowed to chip when the laser beam hits at the predetermined power.

We make this aspect easy for our customers to deal with: We simply have to know the intended use of the laser optics and the desired size, and then we decide on the coating composition and process. All standard technologies are available for this purpose.

Optical Coatings on Other Materials

Even though high-power laser optics constitute a large majority of our coatings, we also coat other products. This includes:

- Coatings for heat-sensitive materials

such as plastic optics or grin lenses - Facet coatings

These are applied, in particular, to optical fibers - Coatings for semiconductors

We also process semiconductors

Optoelectronical Technologies

Beyond Borders

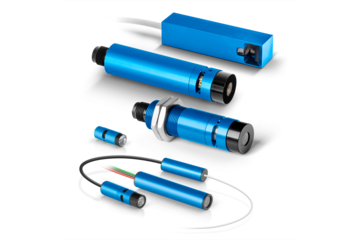

The development of optoelectronic technologies requires cross-disciplinary knowledge: we are competent and bundle knowledge from the areas of mechanics, optics, and electronics to complete complex tasks in a short amount of time.

Opto-electronic components such as laser diodes or photodiodes demand a lot out of control electronics. Small deviations in opto-electronics result in the need for an adjustment when choosing an electronic component to be a deciding component in the success or failure of the entire system. Experience and expertise in this area are necessary to coordinate both components optimally with each other. Important factors such as the noise of a detector or the life expectancy of a laser depend significantly on the quality of the electronic circuit.

In the past few years, we have made a number of electronic developments that have either been accepted into the program as component accessories or produced exclusively for customers as an OEM component. We have made these developments both of our own initiative and together with customers. Do not hesitate to let us know what you have in mind and what your needs are, and our specialists will be more than happy to advise you as to the particulars.

Fiber optical Technologies

Beyond Borders

SM, PM, and MM assemblies: We combine different materials and connectors and manufacture at the highest level of quality. To produce fiber optics for use in medical technology, we have a cleanroom that meets the ISO requirements for class 7 at our disposal.

Directors of R&D

Dr. Richard Kim

+ LASER COMPONENTS Detector Group Dr. Richard Kim joined the LASER COMPONENTS Detector Group in 2023 from California, where he was responsible for leading innovations in Silicon UV detectors, Lead Salts, III-V InAsSb, InAs/GaSb T2SL MWIR detectors and MWIR ICLEDs.

Earlier in his career, he focused on path finding research efforts in the areas of photonic integrated waveguide circuits based on Si and III-V materials, LiNbO3 electro-optic modulators/switches, solar cells etc. He holds tens of US/Korea patents and has published over 60 papers in various conferences and journals.

Dr. Sina Malobabic

+ LASER COMPONENTS Germany. After studying physics and mathematics, Sina specialized in optical technologies as a doctoral scholar at the Laser Zentrum Hannover e.V. and started as a development engineer at LASER COMPONENTS GmbH in 2016.

In 2021, she took over responsibility for technology-oriented tasks, which not only includes the development of coatings and substrate handling, but also the entire measurement technology for optical and optoelectronic components.

Since July 2022, she has also been in charge of product development and manages projects from fiber technology as well as new developments and optimization of optoelectronic components such as laser modules or detectors.

Dr. Saïd Rouifed

+ LASER COMPONENTS Canada Saïd has expertise in III-V and IV semiconductors for optoelectronic and photonic devices, and profits from his significant industrial and academic experience as scientific researcher at University Paris-Saclay (France), Nanyang Technological University (Singapore), and University of Southampton (UK).

He joined LASER COMPONENTS Canada in March 2020 as a senior optoelectronic scientist, focusing epitaxy and microfabrication methods to enhance laser-based products. In 2022, he led the “chip-group”, managing two doctoral candidates and introducing new technologies for pulsed laser diodes. Since 2023, he has overseen the R&D department, focusing on the design, fabrication, testing, and packaging of laser chips.

LASER COMPONENTS Germany - Your competent partner for optical and optoelectronic components in Germany.

Welcome to LASER COMPONENTS Germany GmbH, your expert for photonics components. Each product in our wide range of detectors, laser diodes, laser modules, optics, fiber optics, and more is worth every Euro (€/EUR). Our customized solutions cover all conceivable areas of application: from sensor technology to medical technology. You can reach us here:

Werner-von-Siemens-Str. 15

82140 Olching

Deutschland

Phone: +49 8142 2864-0

Email: info(at)