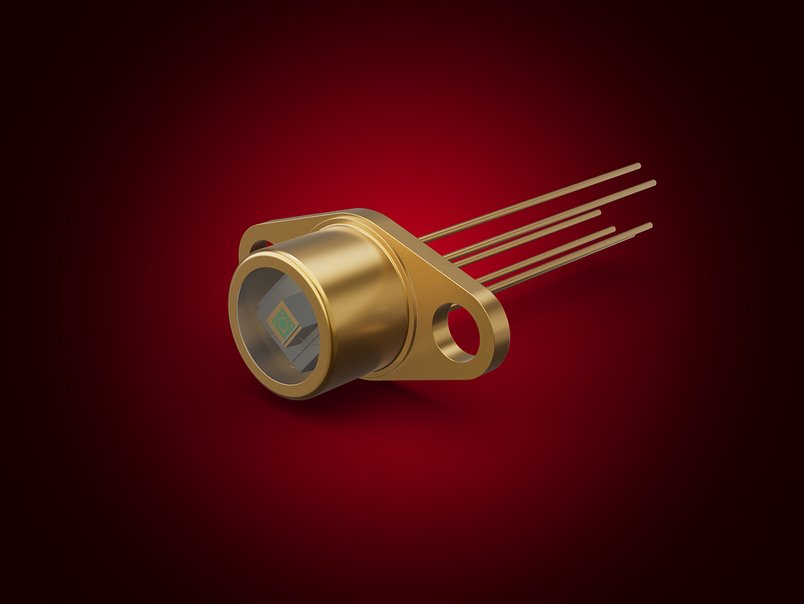

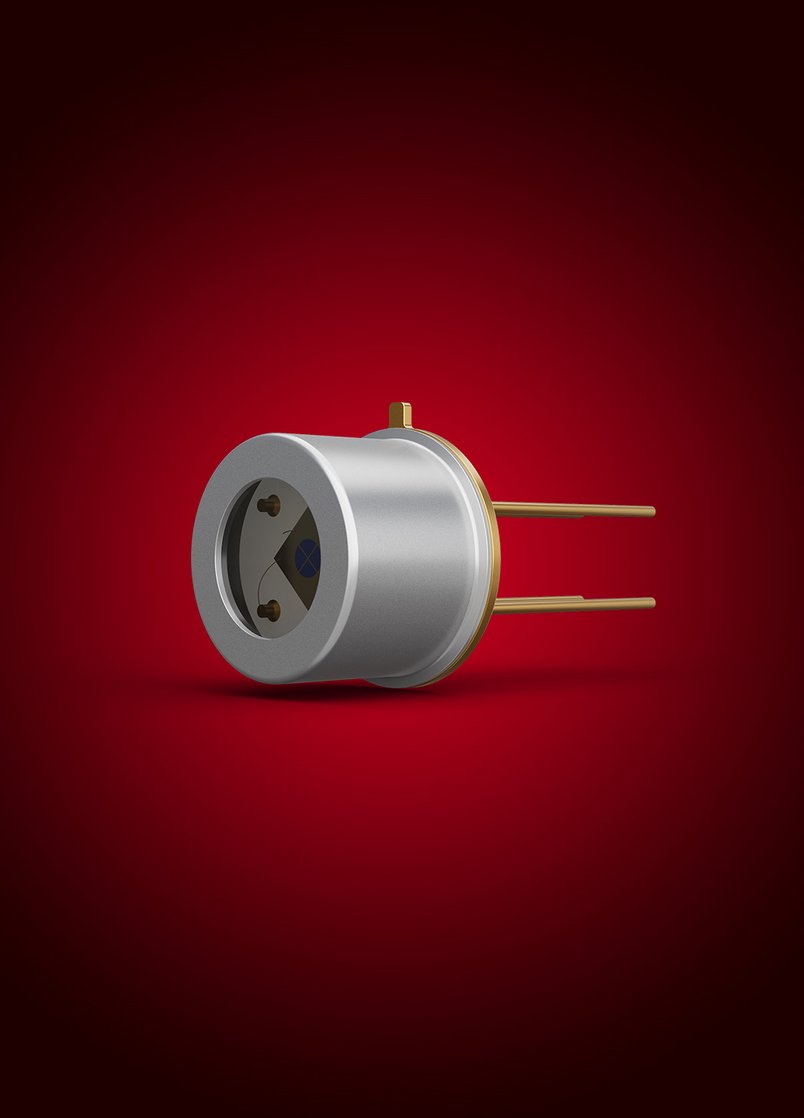

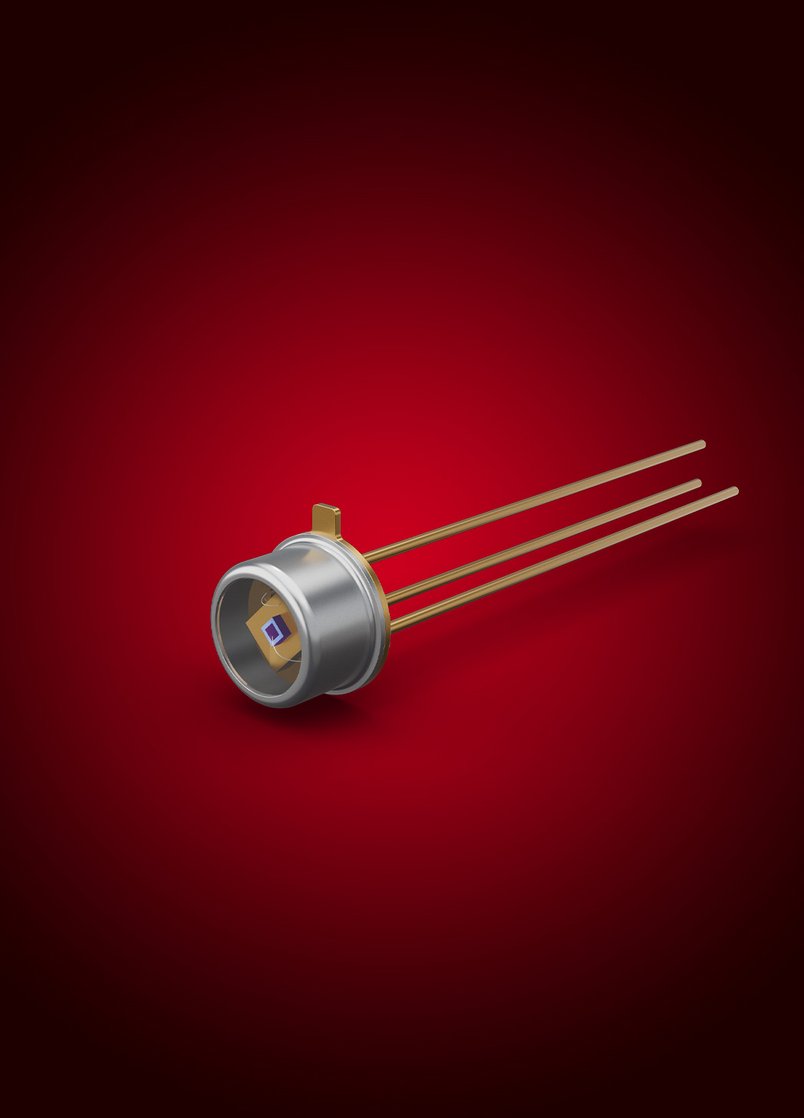

With a fully automated measuring station from Swabian Instruments, LASER COMPONENTS has the ability to test up to twelve COUNT photon counters simultaneously for all crucial values. The new technology and continuous process optimization has not only succeeded in accelerating the quality control of COUNT modules, but measurement accuracy has been improved as well. Customers can be assured that the photon counters operate with the highest precision and lowest possible error tolerance.

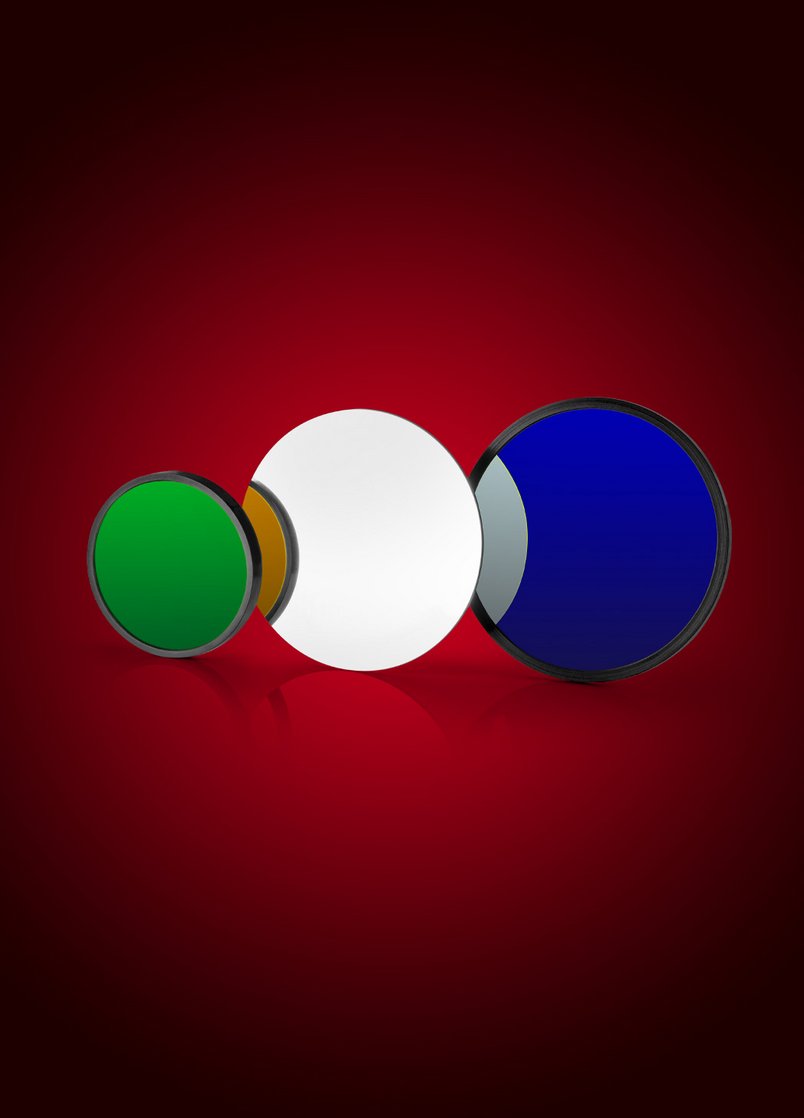

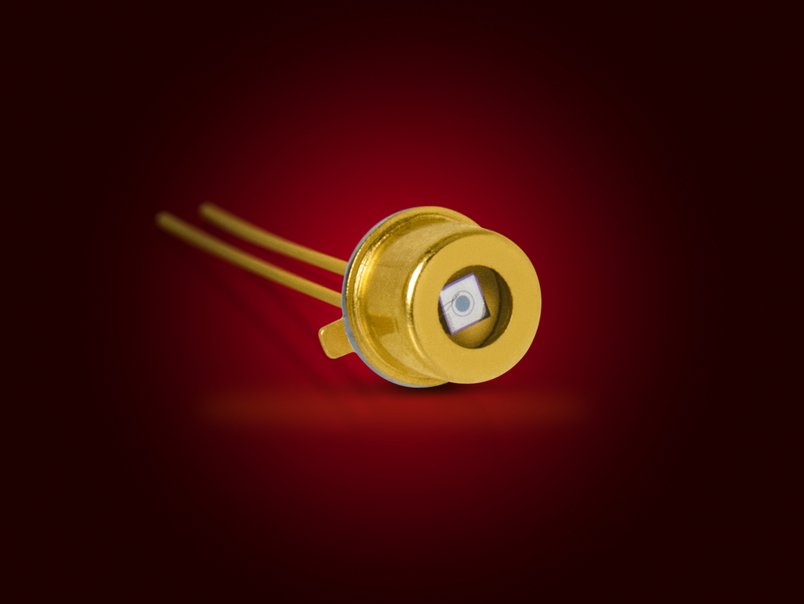

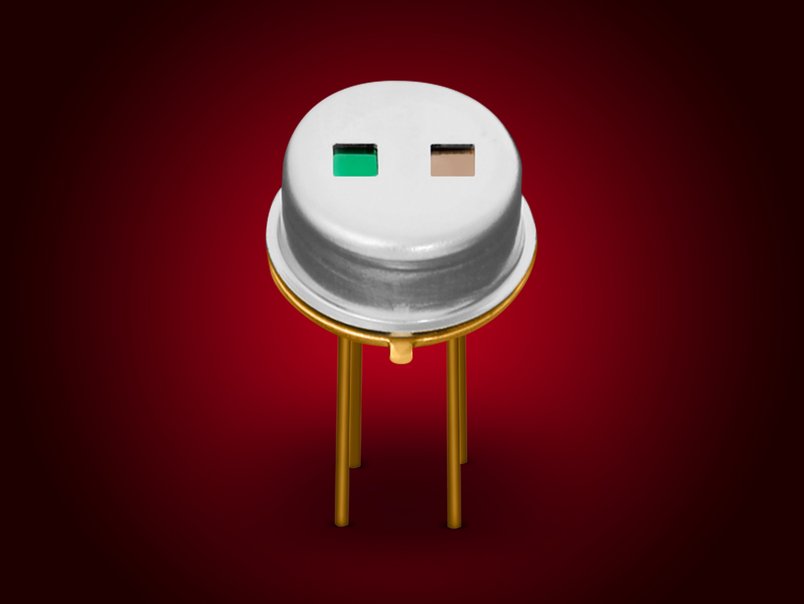

The measuring station is tailored precisely to the requirements of the Olching-based company. At its core is a Time Tagger Ultra from Swabian Instruments. A proprietary data processing architecture makes this technology particularly well suited for time-correlated single photon counting (TCSPC), time interval counting, and coincidence counting. LASER COMPONENTS uses it in conjunction with ultra-short-pulsed diode lasers, high-precision reference power meters, and computer-controlled moving tables. At four wavelengths (405 nm, 505 nm, 670 nm, and 804 nm), performance parameters such as jitter, dark count rate, afterpulsing, dead time, and detection efficiency are determined. COUNT modules can be tested with or without fiber coupling. The results are digitally logged for later access as part of trend analysis.

“Through the cooperation with Swabian Instruments, we obtained a measuring station that is optimally adapted to our processes,” explains Dr. Lars Mechold, technical director at LASER COMPONENTS. “This not allowed us to further improve the quality control of our products. The optimized manufacturing process means shorter delivery times and better availability for our customers.”