How to Choose Pyroelectric Detectors?

Materials, Applications, and Working Principle

LASER COMPONENTS – Experts in Pyroelectric Detector Manufacturing

Pyroelectric detectors are thermal detectors: temperature fluctuations produce a change in surface charge on pyroelectric materials, which produces a corresponding electrical signal This temperature gradient is usually triggered by an absorber that converts incident light into heat. There are various pyroelectric materials available, three of which are commonly used in pyroelectric detectors: DLaTGS, LiTaO₃ (LTO), and PZT.

Material Properties

and Pyroelectric Detector Element Construction

The table below provides an overview of the properties of each material. Simply put, the figures mean the following:

- The pyroelectric coefficient determines the ability to produce current from infrared radiation. That is to say: the bigger, the better.

- The dielectric constant (at room temperature) determines the capacitance, thereby affecting the noise. In voltage operation, the following is true:

The larger the capacitance, the lower the noise. The dielectric constant (at room temperature) corresponds in the exact opposite manner. - The specific heat capacity determines the temperature increase in the pyroelectric material depending on the absorbed radiation. A low Cv means a larger temperature increase and thus a better signal.

- The specific AC resistance is coupled with dielectric losses that, in turn, produce a kind of Johnson noise. A pure dielectric would not produce any noise. The lower the AC resistant, the better.

DLaTGS

Pyroelectric coefficient: 4.5 x 10-8

δ [Coul/cm² °K]

Dielectric constant

(at room temperature): 18

ε

Specific heat capacity: 2.5

Cv [J/cm3 °K]

Specific AC resistance: 2.4 x 1010

ρ [Ω -cm]

Figure of merit: 24

δρ/εCv

LiTaO3

Pyroelectric coefficient: 1.7 x 10-8

δ [Coul/cm² °K]

Dielectric constant

(at room temperature): max. 51 (anisotrope)

ε

Specific heat capacity: 3.2

Cv [J/cm3 °K]

Specific AC resistance: 4.2 x 1010

ρ [Ω -cm]

Figure of merit: 4.3

δρ/εCv

PZT

Pyroelectric coefficient: 4.4 x 10-8

δ [Coul/cm² °K]

Dielectric constant

(at room temperature): 180

ε

Specific heat capacity: 2.6

Cv [J/cm3 °K]

Specific AC resistance: 4.2 x 109

ρ [Ω -cm]

Figure of merit: 0.4

δρ/εCv

To compare materials in terms of their fundamental suitability for pyroelectric detectors, it makes sense to analyze them using the following parameters: pyroelectric coefficient, specific AC resistance, dielectric constant, and specific heat capacity. DLaTGS and LiTaO₃ achieve the best results and are therefore particularly well suited.

DLaTGS offers the highest performance detectivity (approx. 2 × 10⁹ Jones @ 10 Hz) and is widely used in IR measurement technology in laboratory settings, especially in routine FTIR applications. Industrial applications are largely the domain of LiTaO₃ due to its favorable thermal behavior (Fig. 1). PZT is primarily used in consumer products.

Click here

How to Choose Pyroelectric Detectors

Current vs Voltage Mode

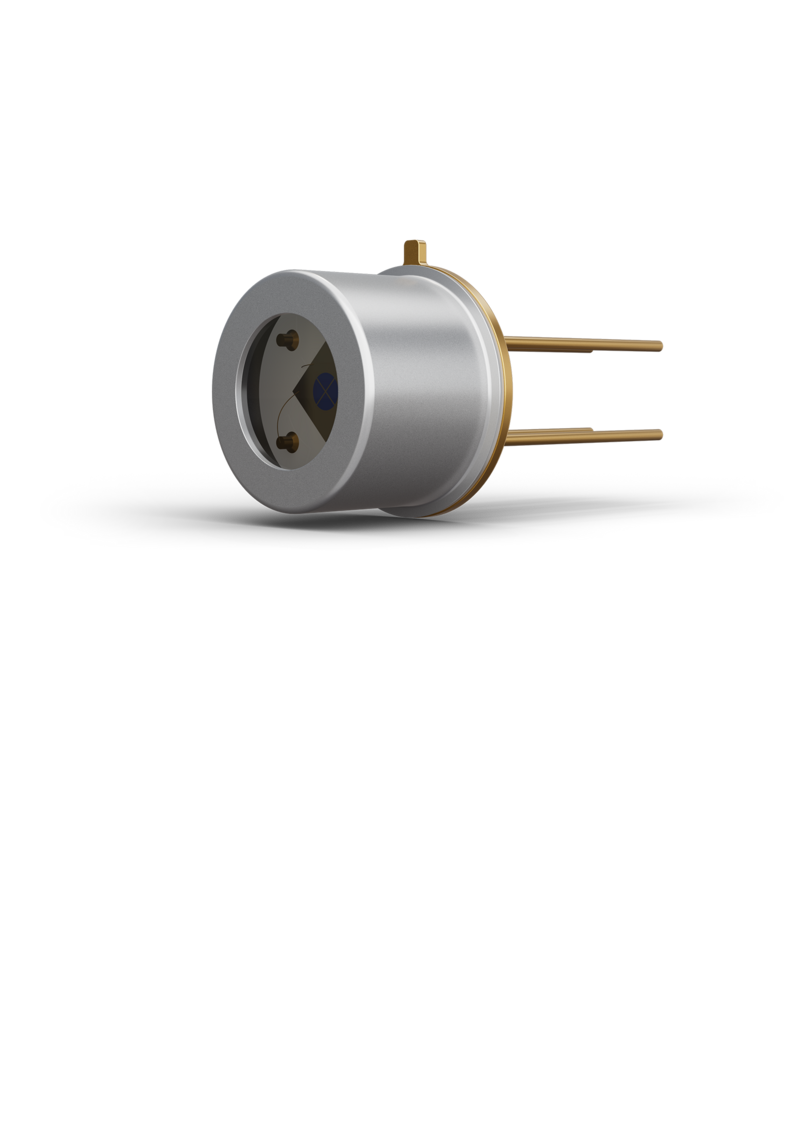

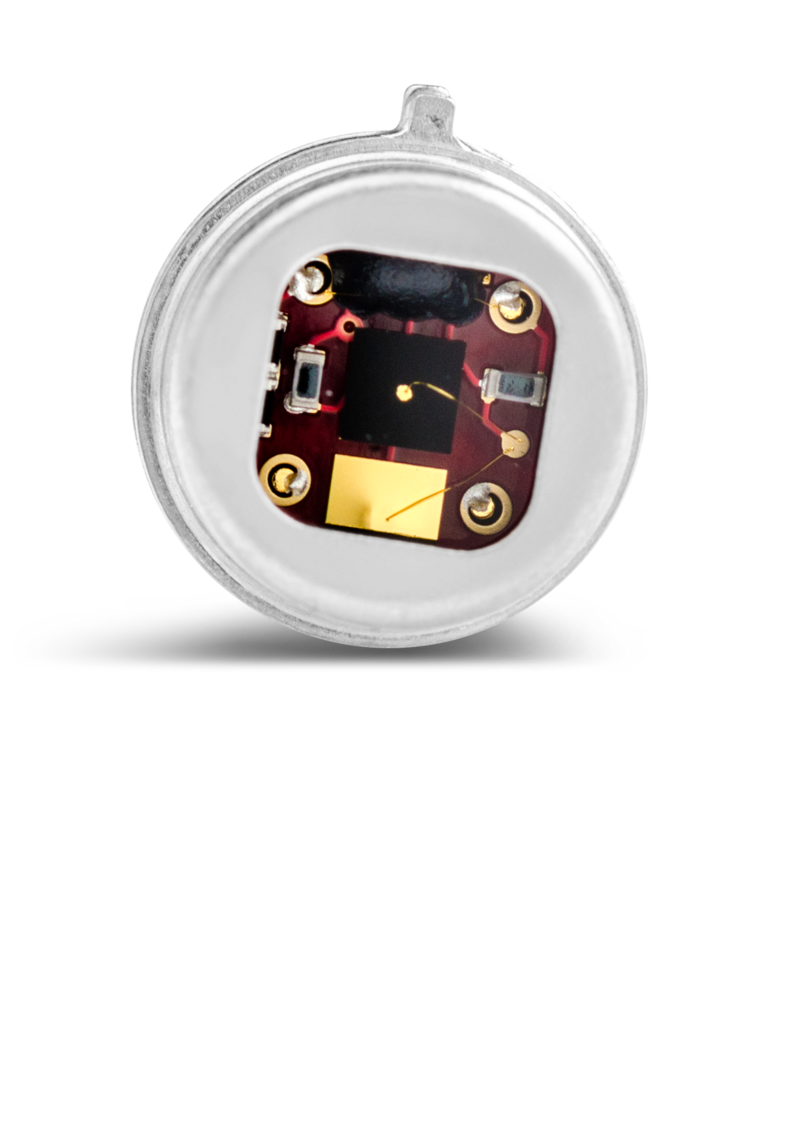

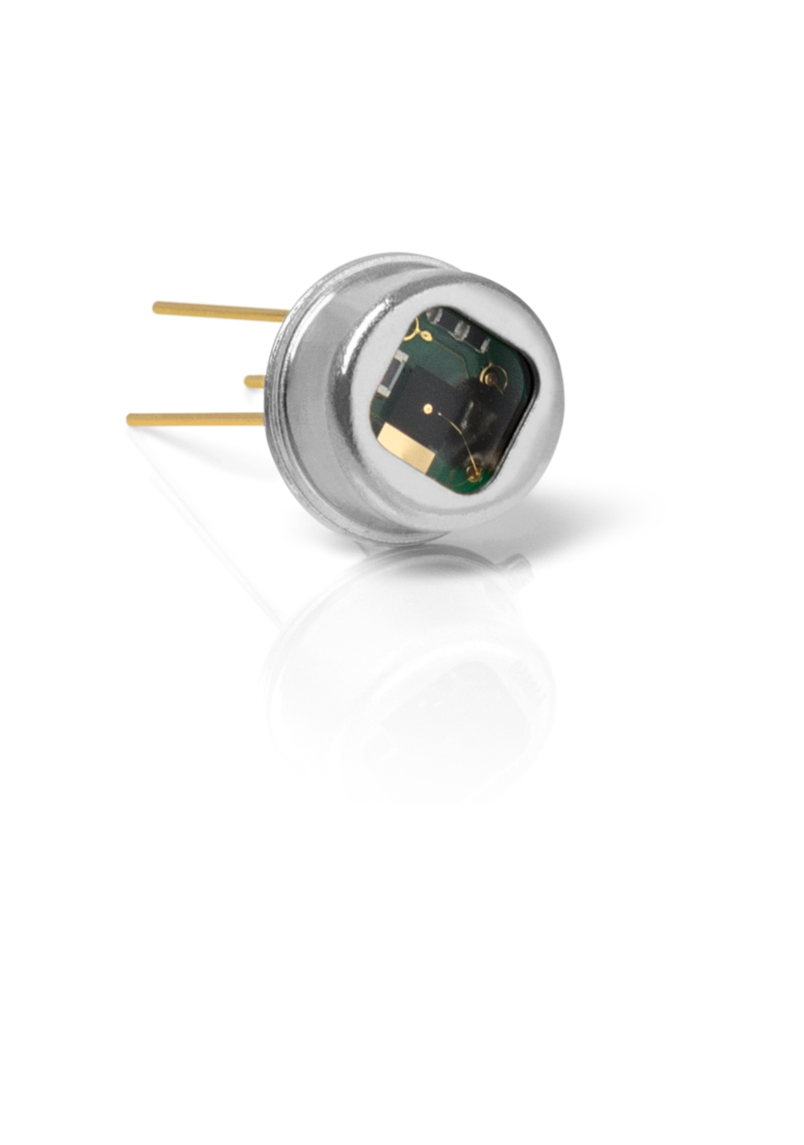

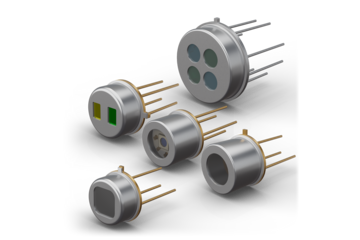

The IR crystal is modulated as a power source with a parallel capacitance and housed in a TO can with additional electronic components. There are two basic modes of operation of pyro detectors: voltage mode (VM) (Fig. 2) and current mode (CM) (Fig. 3).

Voltage Mode: Pros and Cons:

JFET-based voltage mode has been widely used in pyroelectric detector applications for many years. However, integration comes with significant challenges and is best suited for experienced users.

Main Voltage Mode Challenges:

- A relatively low output signal

- A strongly temperature-dependent offset

Advantages of Voltage Mode:

- It provides flexible amplification options

- It enables the highest possible D* value with a simple design (approx. 0.5 × 10⁹ Jones @ 10 Hz)

Why Current Mode (CM) Detectors?

Current mode (CM) offers several advantages like high responsivity for pyroelectric detector applications.

Key Benefits of Current Mode:

- Produces high signal on a low offset, with minimal temperature dependence

- Requires low-power operational amplifiers (OpAmps)

- Easy to implement, making it ideal for beginner-level product development

- Features low output impedance, which improves EMC performance

D Performance and Design Considerations

- High D* (detectivity) values in current mode are comparable to those in voltage mode.

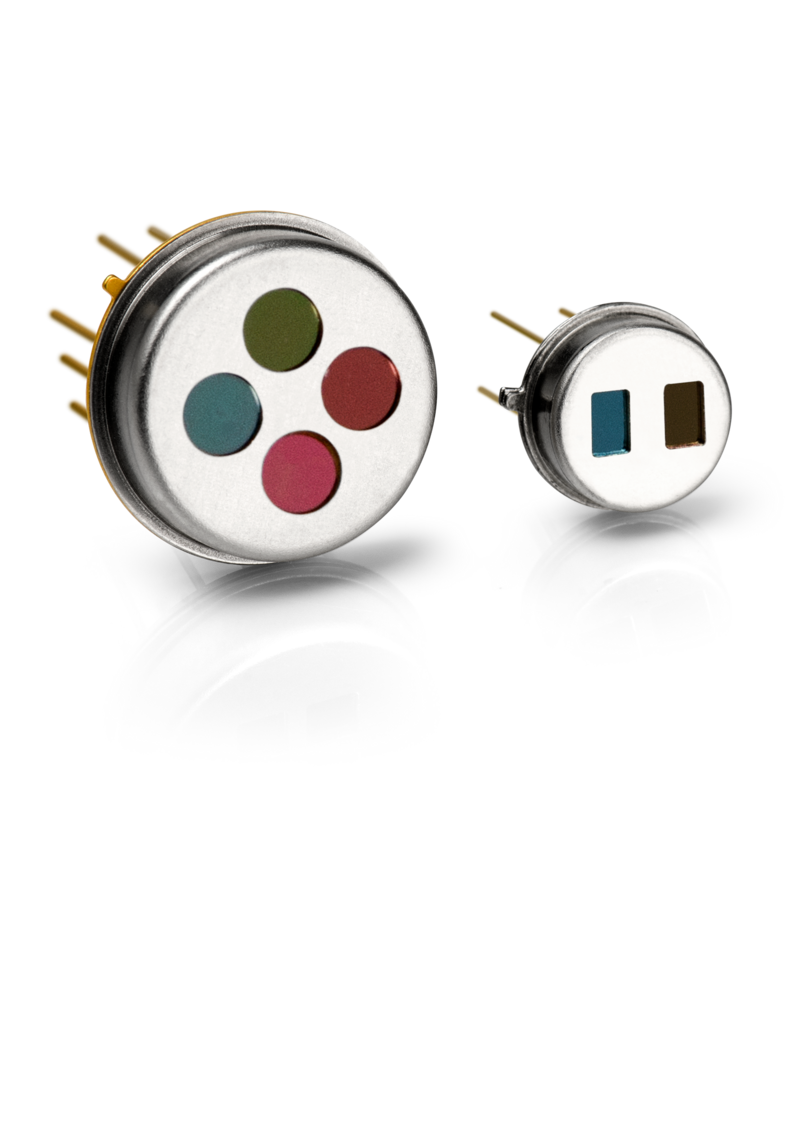

- The design is slightly more complex than voltage mode because to reach this impressive D* the detector can be connected to a second blind detector element in antiparallel.

- This design—even though it is not the best term—is commonly referred to as "temperature compensation" (TC).

What Temperature Compensation Really Does

- The blind detector element reduces unwanted signals caused by fluctuations in ambient temperature.

- However, it does not compensate for inherent temperature dependencies of the detector material (see Fig. 1).

- A more accurate term would be "temperature fluctuation compensation" (TFC) or signal stabilization.

Effect of TFC on Performance

- In current mode, TFC improves performance by attenuating toward natural oscillations, enabling greater signal amplification.

- In voltage mode, however, TFC can reduce performance by approximately 50%.

Good to Know

What is D*?

Detectivity D*

“D* represents the signal-to-noise ratio (SNR) for a certain electrical frequency and bandwidth if 1 watt of radiation power reaches a detector surface of 1 cm2. The higher the D* value, the better the detector.”

Original from October 2018

Last revision September 2025

Components Ranging from Standard to OEM

Find the Right Part or We Make It

The LASER COMPONENTS Detector Group manufactures pyroelectric detectors based on both DLaTGS and LiTaO3. Our portfolio ranges from all commercially available options, from multicolor and miniaturized versions to detectors with a low-microphonic effect, and continues to expand so that LASER COMPONENTS can be your one source for detection solutions.

For detailed information about the products listed below, or to discuss custom components tailored for specific applications, our product engineers are ready to help. Just fill out the form below to get in contact.

LASER COMPONENTS (UK) Ltd.

Downloads

Beyond Borders

LASER COMPONENTS UK - Your competent partner for optical and optoelectronic components in the United Kingdom.

Welcome to LASER COMPONENTS UK Ltd., your expert for photonics components. Each product in our wide range of detectors, laser diodes, laser modules, optics, fiber optics, and more is worth every Pound (£/GBP). Our customized solutions cover all conceivable areas of application: from sensor technology to medical technology. You can reach us here:

4 William House, Old St Michaels Drive

Braintree CM7 2AA

United Kingdom

Phone: +44 1245 491 499

Email: info(at)