Every object radiates heat in the form of electromagnetic waves with the wavelength of the light emitted depending on temperature. Radiation generated at longer wavelengths is associated with colder objects. Measuring the energy emitted into space allows the temperature of the target to be established without ever having to touch it. Thermopile detectors are ideal for this application with high temperature stability, excellent signal to noise and low cost. LASER COMPONENTS has been working with Dexter Research Centre, a world leading manufacturer of thermopile detectors.

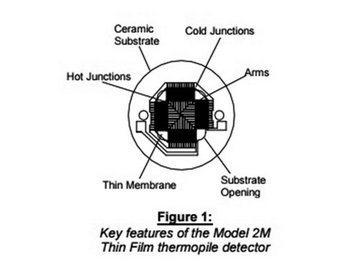

Figure (1) illustrates the layout of a typical thermopile detector manufactured by Dexter. The sensor consists of a series of hot and cold junctions forming a thermocouple array mounted on a ceramic substrate which contains an aperture. Alternating n- type and p-type material connect the junctions together. The cold junctions are in thermal contact with the detector housing and are distributed around the perimeter of the substrate opening. The hot junctions define the active area of the sensor and are coated with an energy absorber. They are located in the centre of the detector and are supported on a thin membrane, thermally isolating them from the rest of the package.

The voltage generated is proportional to the temperature gradient between junctions and, unlike pyroelectric detectors, thermopiles are inherently low noise producing no 1/f or microphonic noise. In addition, thermopile detectors provide a stable output for DC radiation up to a frequency limited by the time constant of the sensor.