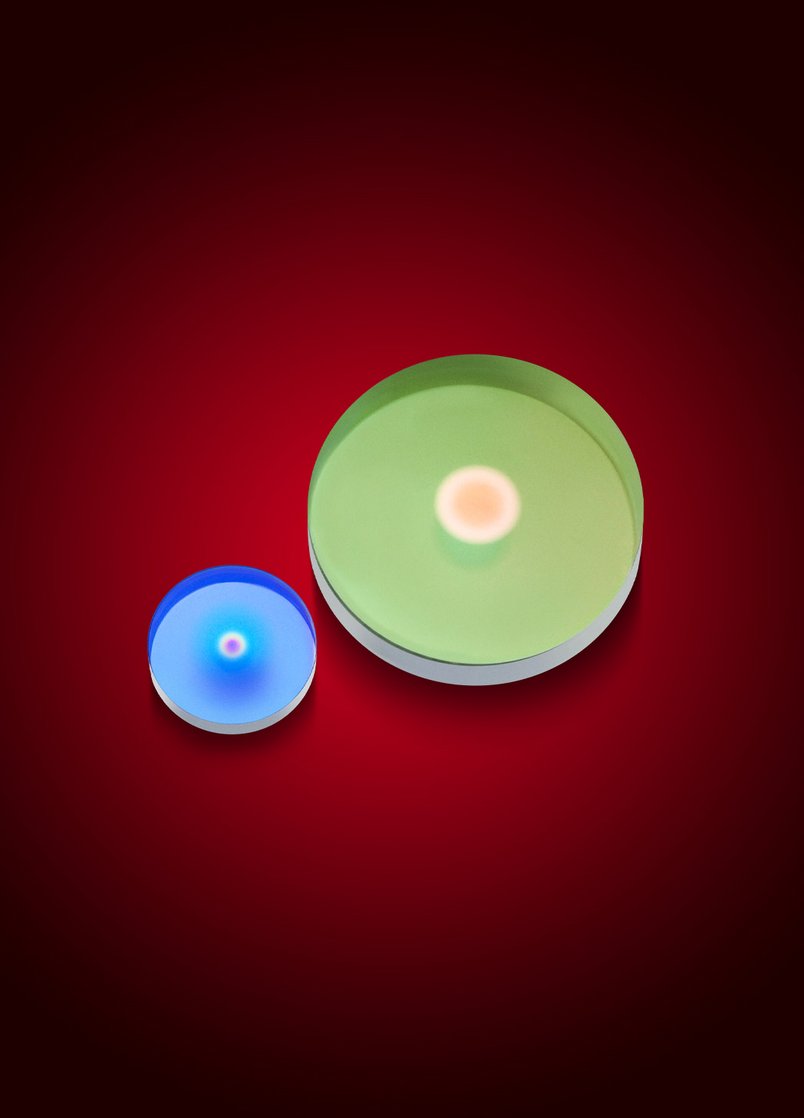

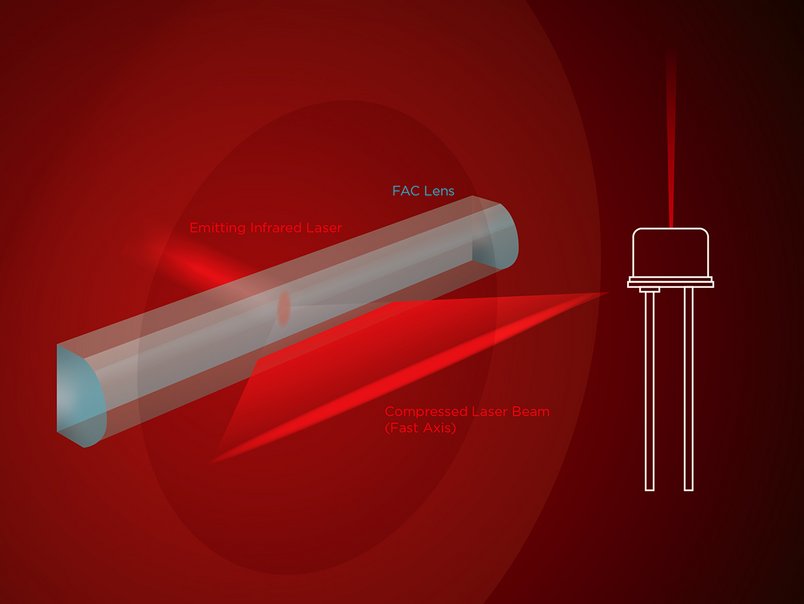

LASER COMPONENTS optics were subjected to an intensive stress test at a laser power of 40 kW by a well-known manufacturer of laser cutting processes. Specifically, aspheres with an anti-reflective coating (brief: AR aspheres) proved their functionality in various configurations when tested with a continuous wave laser.

The stress test was scheduled because the manufacturer is aiming to double the laser power (from 20 kW to 40 kW). The question therefore arose as to whether the aspheres with anti-reflective coating from LASER COMPONENTS, which had been specially optimized for laser cutting, would be able to withstand the increased power density.

LASER COMPONENTS looked forward to the test with confidence because a previously conducted LiDT measurement - a measurement in which the laser power is continuously increased until the optics are destroyed (irreversible change in the material structure) - had shown that the anti-reflective aspheres can even withstand a power density of at least 38 MW/cm².

The maximum destruction threshold could not be determined during this measurement, as the test house commissioned was not in possession of a laser that could generate power densities of more than the said 38 MW/cm².

If the power density of the LiDT test house is transferred to the 40 kW cutting laser, the result is that the beam of the cutting laser would have to be collimated to an industrially unrealistic diameter of 366 µm in order for the new power density (> 38 MW/cm²) to cause an irreversible change in the material structure of the asphere and its coating.

Optics coated by Laser Components pass endurance stress tests

AR aspheres show LiDT test house limits and 40kW cutting laser the cold shoulder

05.12.2023

Contacts

Head of Business Unit Laser Optics

Barbara Herdt

LASER COMPONENTS Germany GmbH

82140 Olching