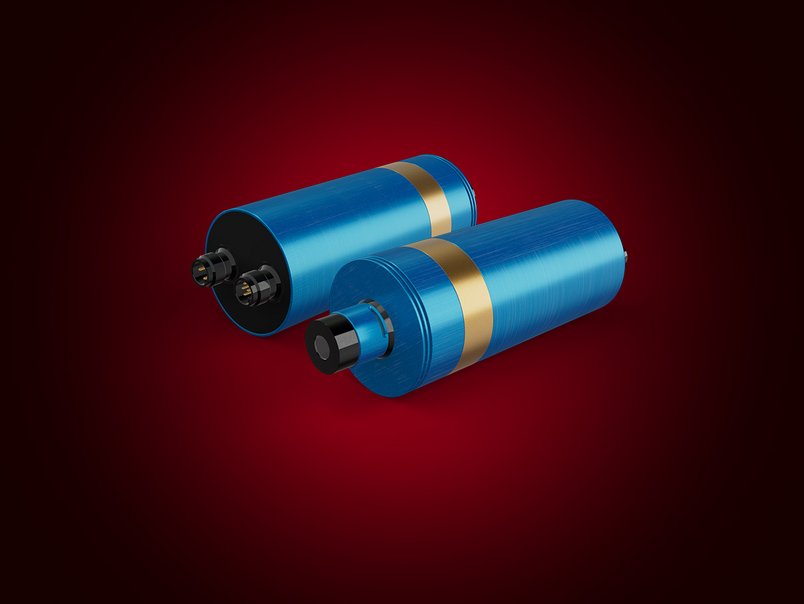

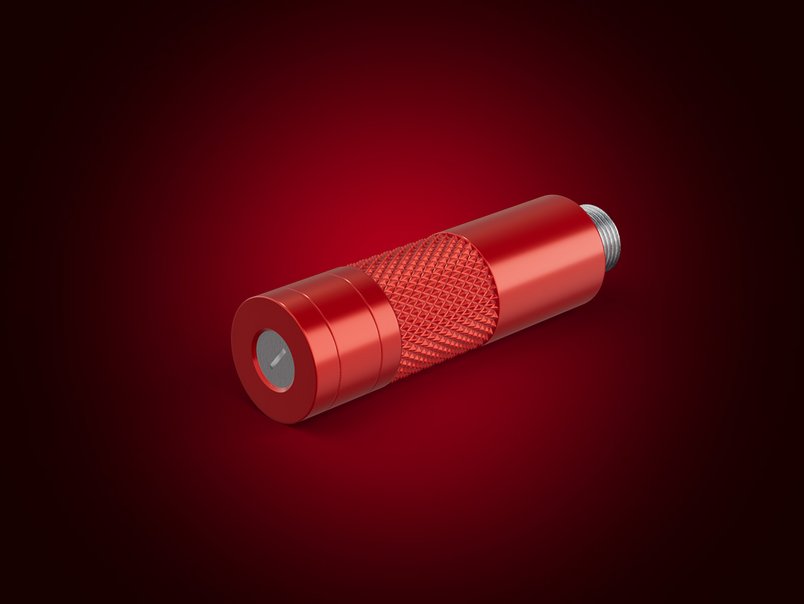

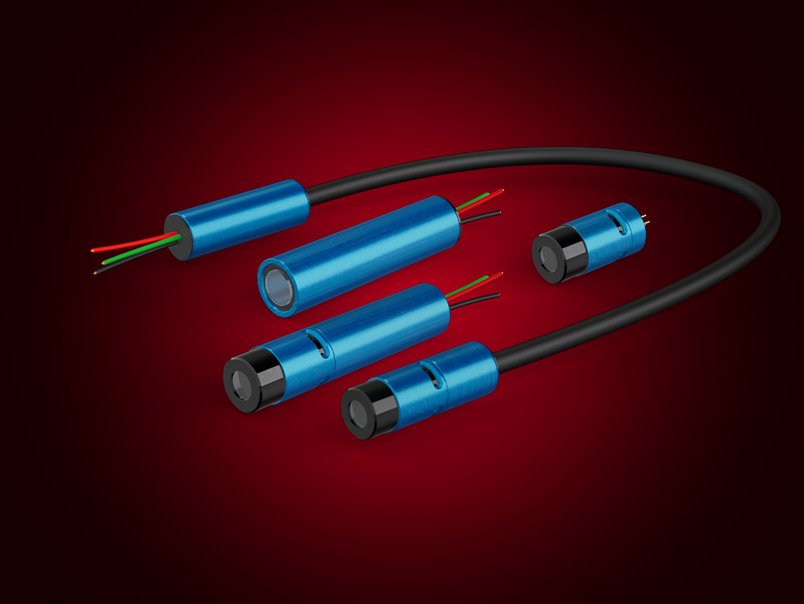

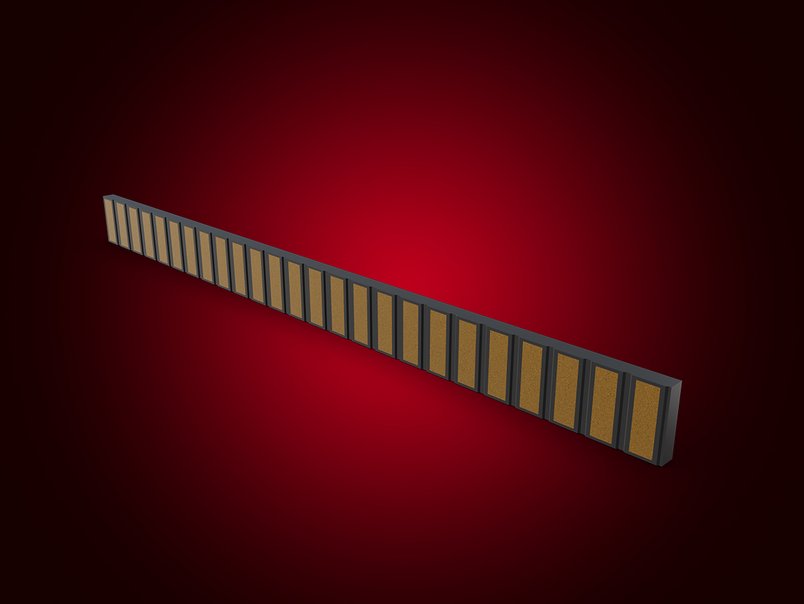

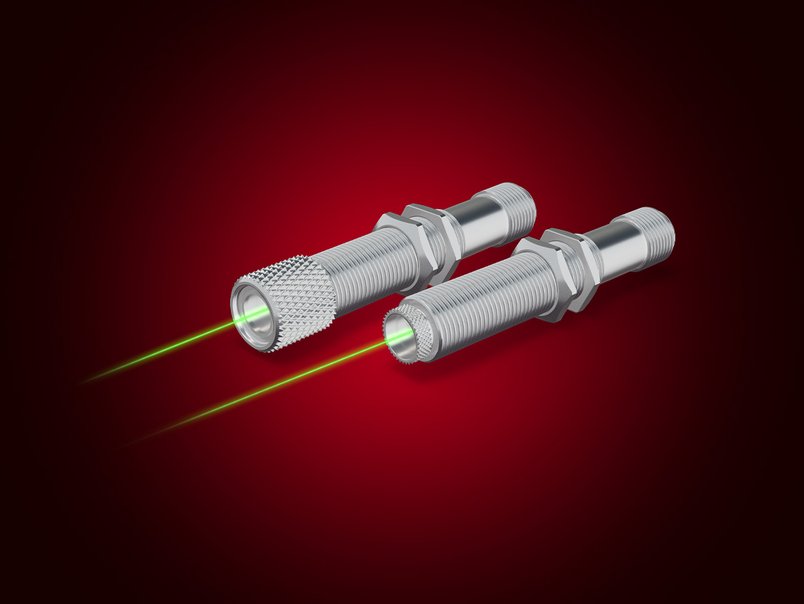

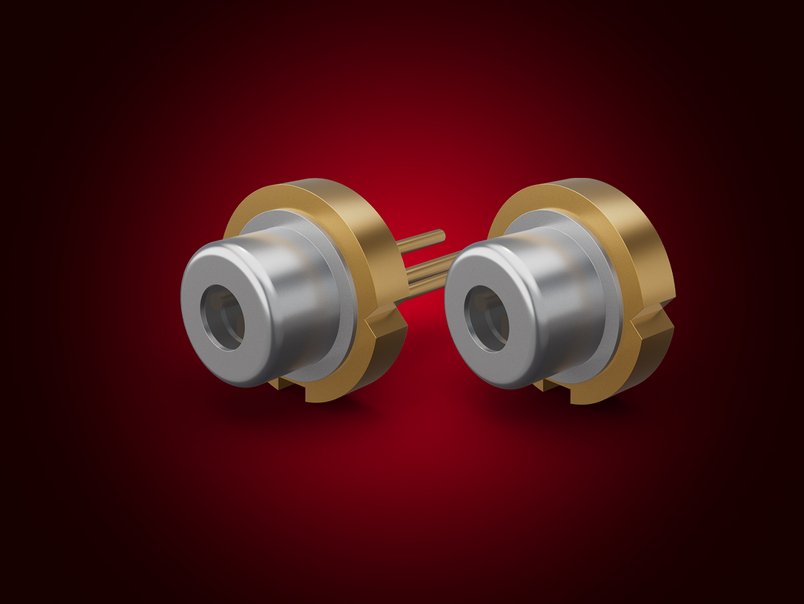

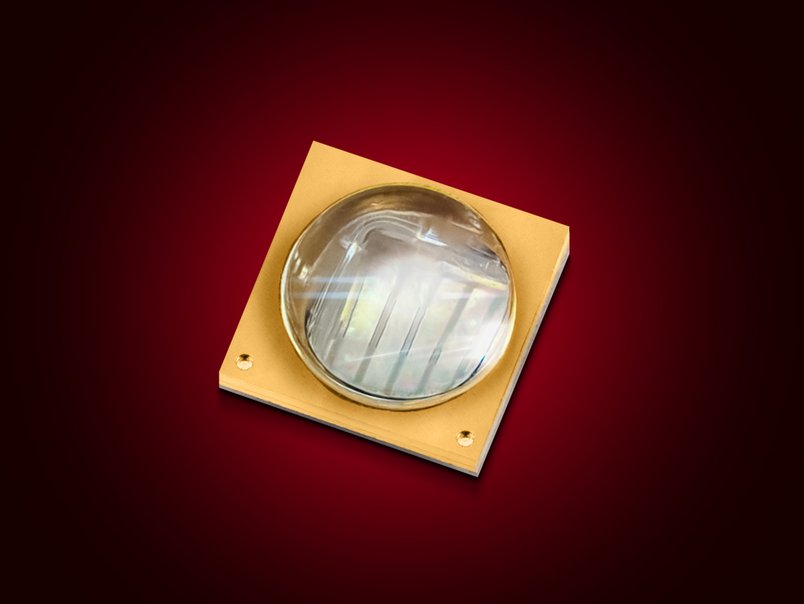

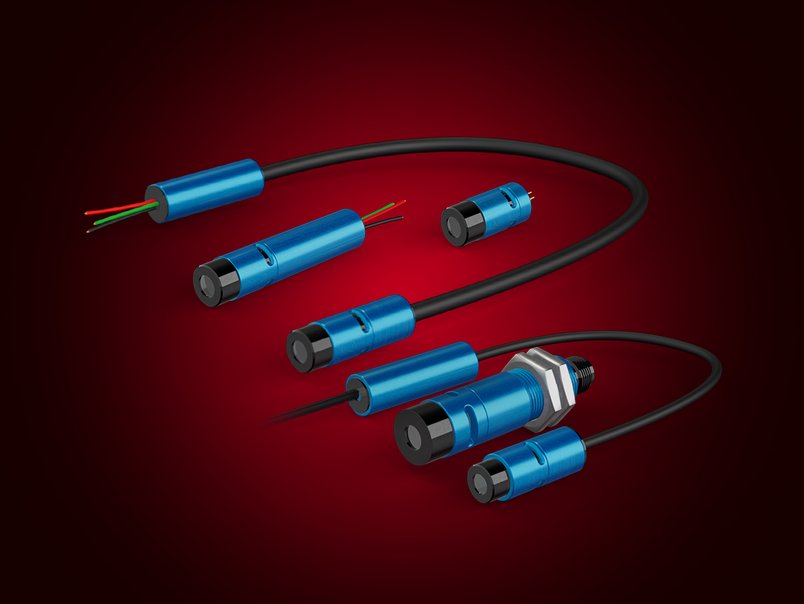

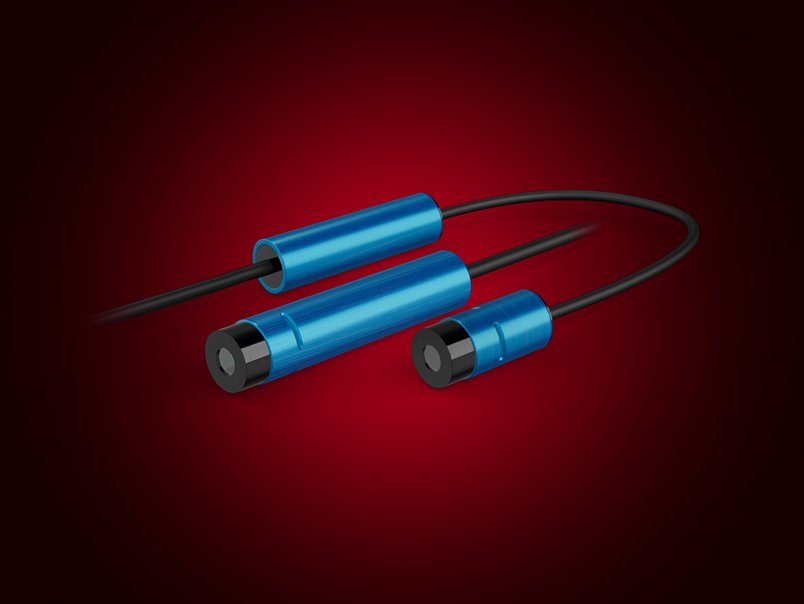

LASER COMPONENTS has taken a decisive step towards more efficient production processes by acquiring a new robot. For almost a year now, the "mechanical colleague" has been carrying out a crucial first step in the production of laser modules: It ensures that the laser diodes, which later generate the light for the FLEXPOINT® modules, are firmly attached to their heat sinks. This allows the manufacturer to completely eliminate any use of glue during this production step. Since September 2023, the robot has pressed and installed some 2,800 laser diodes.

"Our robot allows us to kill several birds with one stone," says Felix Berres, the technologist in FLEXPOINT® production who takes care of everything related to the new "worker". "The automated pressing process makes our FLEXPOINT® modules more robust. By replacing the glued connection with a pressed connection, we can also optimize heat dissipation, which in turn has a positive effect on the service life of our modules."

The robot also reduces the workload for employees in production, as it relieves them of a tedious part of their work so that they can concentrate more on their most important task: configuring the FLEXPOINT® modules so that they precisely meet the customer's requirements. "At LASER COMPONENTS, we focus on our customers and their wishes and requirements," emphasizes Dr. Lars Mechold, Technical Director at LASER COMPONENTS Germany. "By transferring monotonous routine tasks to the robot, we can put more focus on this important part of our work. No two customer orders are the same for us. The technical experience and skill of our employees ensures that every customer gets exactly what they need for their application."