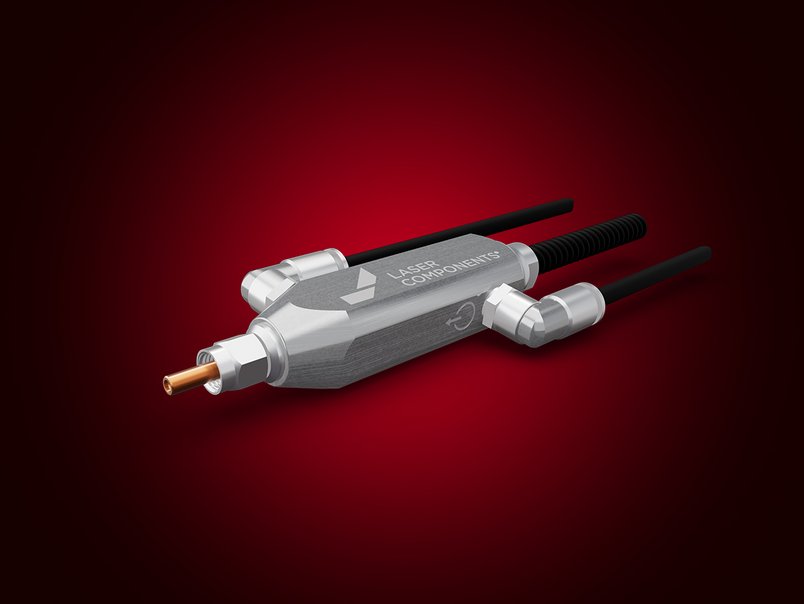

LASER COMPONENTS can now provide custom ball lens profiles on the end faces of silica fibers. The plasma-based CMS process with ring-of-fire technology supports fiber diameters of 200, 365, 400, 550 and 600 μm, including other diameters within the limits of the equipment. For fibers used in medical applications, end-face processing can be carried out in a clean room in accordance with ISO 13485. The entire process is also compliant to ISO 13485 hygiene requirements.

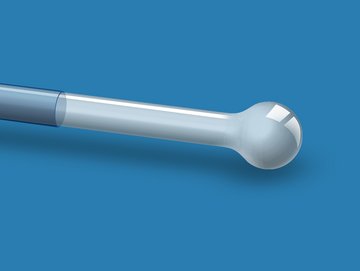

High sterile standards are important since these fibers with spherical lenses are often used in medical technology applications to optimize radiation characteristics in endoscopes for example. The rounded surface of the ball lens reduces the risk of injury during the operation whilst at the same time controlling the beam characteristics of the laser. The same type of fiber tips is also used in other applications for coupling light sources with the fiber.

LASER COMPONENTS can meet all customer demands from single fibers to small series and, upon request, we can also conduct research projects. Ball lens fibers can also be integrated into OEM products. Other fiber tip modifications are also available upon request.