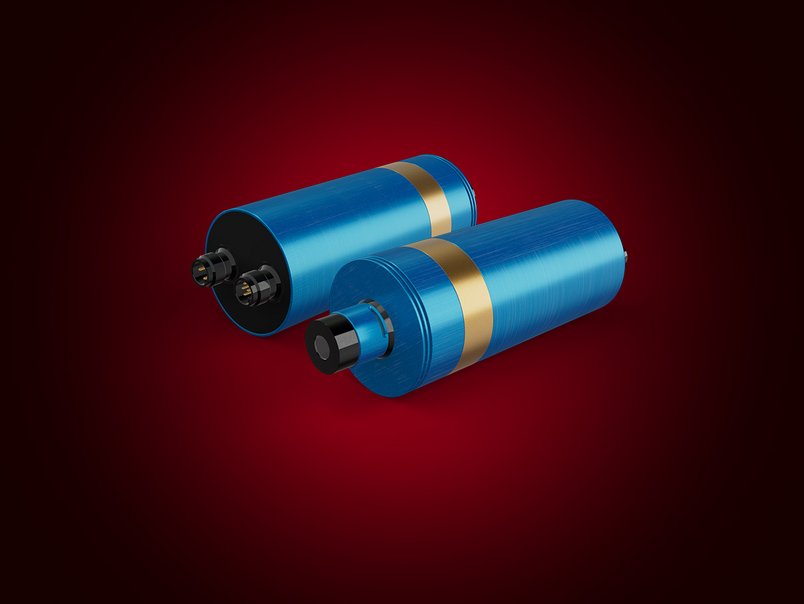

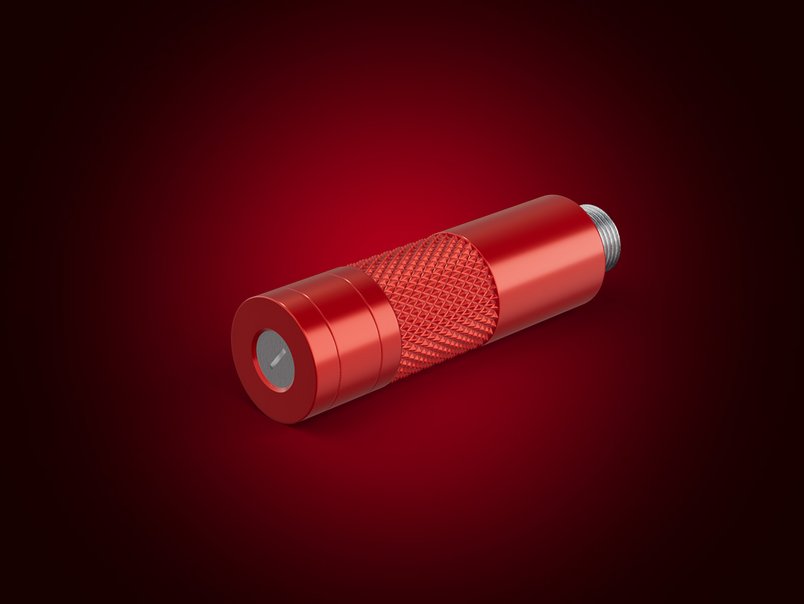

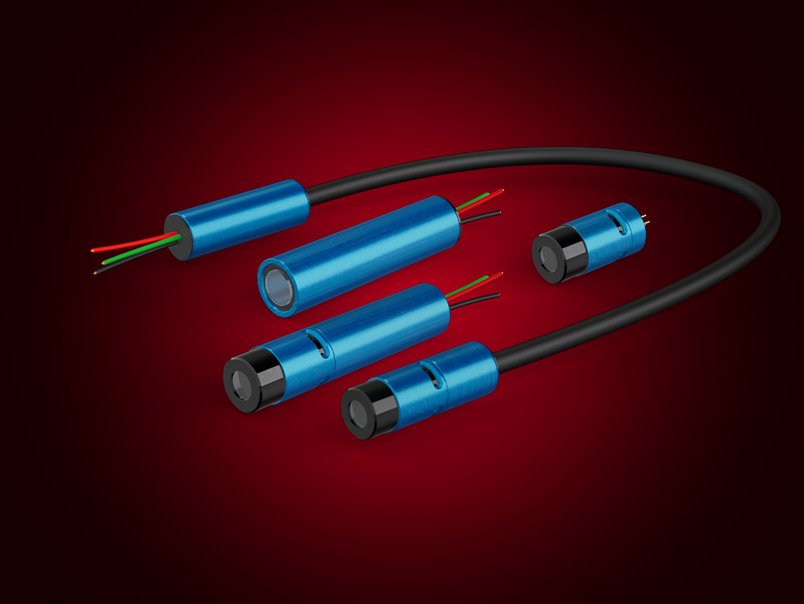

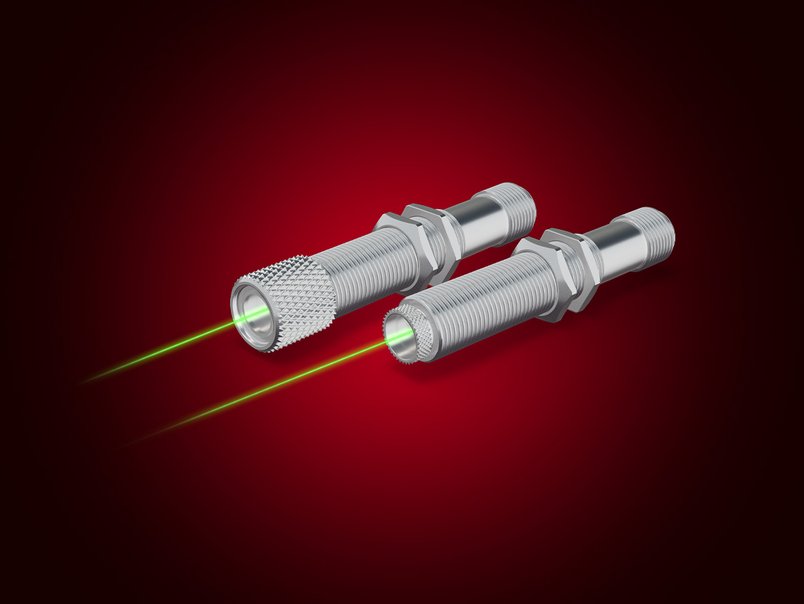

LASER COMPONENTS will be presenting the FLEXPOINT® MVpulseHP at VISION 2024. This laser module has a laser power of up to 1000 mW. Despite its high power, the laser module does not require active cooling and therefore retains a standard diameter of 19 mm. This makes it ideal for open-air inspection tasks, such as the inspection of roads and rails.

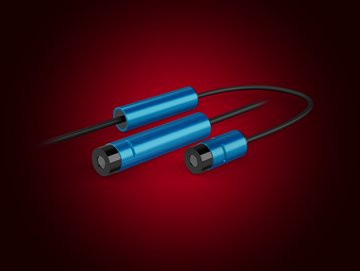

The laser beam of the MVpulseHP is emitted in pulses that are controlled by an integrated microcontroller. The maximum pulse length and duty cycle are preset at the factory so that the laser diode cannot overheat. This makes it possible to guarantee the high output power permanently without additional cooling while maintaining the compact design for which the FLEXPOINT® modules are known. The entire module is 90 mm long in the standard housing. The output signal of the MVpulseHP can be connected to the modulation signal of a camera or controller. The manufacturer is happy to customize the factory setting of the duty cycle to the specifications of each application.

The FLEXPOINT® MVpulseHP is available in the wavelengths 445 nm (500-1000 mW), 520 nm, 660 nm, and 808 nm (300-500 mW each). The operating temperature ranges from -10°C to +30°C. At a wavelength of 445 nm, the module can even be used at up to +50°C. The pulse length can be adapted to the application in the range between 20 µs and 20 ms.

The combination of high light intensity and compact design improves efficiency, resolution, and precision in image processing. It enables shorter exposure times and increases throughput. The MVpulseHP is ideal for outdoor applications such as the detection of defects and the inspection of weld seams on railroad tracks or the monitoring of train wheels.