Diffractive Optics: compare Stable Top Elements and Top-Hat Designs

In many industries, there is a need to focus a laser beam to a well-defined size and shape with uniform intensity and sharp transition regions, enabling consistent laser treatment and creating a clear boundary between treated and untreated zones. For over a decade, Holo-Or has supplied both custom and standard Top-Hat Elements that accept a well-defined Gaussian beam and transform it into a uniform-intensity spot in the target work plane. Over time, customers requested a design that is less sensitive to the input beam’s position, orientation, and quality, leading to the introduction of the Stable-Top design family. This technical note helps users understand the functionality and design considerations of Top-Hat elements and highlights the differences between the traditional Top-Hat concept and the new Stable-Top approach.

Click here

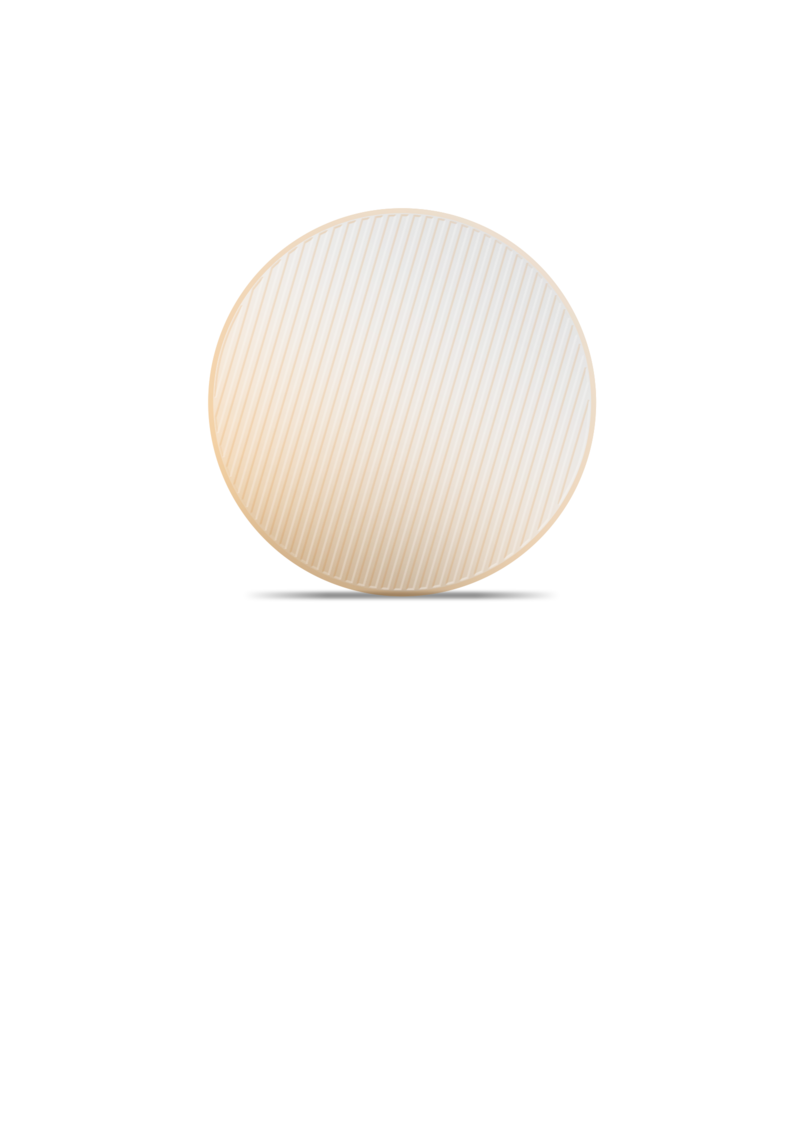

Diffractive Top-Hat Shaper

Principle of Operation

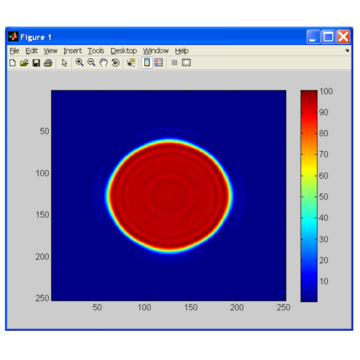

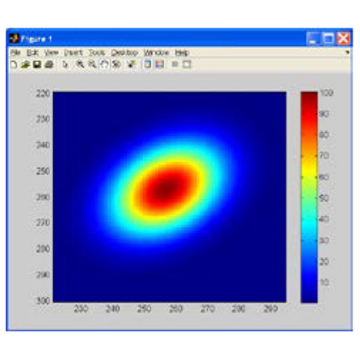

The most basic setup for a Top-Hat application consists of a laser, a diffractive Top-Hat element, and the surface to be treated (see Fig. 1). The diffractive Top-Hat shaper is a phase element that transforms the Gaussian input beam into a uniform spot with sharp edges at a specific working distance (WD).

Note: The Top-Hat spot does not occur at the beam waist (minimum spot size), but near it.

Each Top-Hat shaper is designed for use with a specific set of optical parameters:

- Wavelength

- Input beam size (Din)

- Working distance (WD)

- Output spot size (Dout)

Changing any one of these parameters will degrade the performance of the Top-Hat element and may even render it unusable. For example, a Top-Hat designed for a 50 mm working distance will not produce a high-quality spot at 100 mm; changing the working distance typically requires a different Top-Hat element to correct for the aberrations introduced by the new optical configuration.

Design Considerations

For optimal Top-Hat performance, the laser output should be single-mode (TEM₀₀) with an M² value below 1.3. Even if M² is higher, it may still be possible to reduce it by inserting a spatial filter between the laser and the DOE lens component.

The spatial filter consists of a focusing lens, a small aperture in the focal plane, and a collimating lens. Its aperture reduces parasitic modes, which increase M² and degrade Top-Hat performance. Care must be taken to use a small aperture, but no smaller than twice the beam size at the aperture plane. Too small an aperture can produce parasitic interference patterns or ripples in the Top-Hat output spot.

By adjusting the focal lengths of the two lenses, the spatial filter can also function as a beam expander (see Fig. 2).

Working with a larger input beam offers two advantages. First, it reduces the sensitivity of the Top-Hat output to minor deviations. Second, a larger input beam enables achieving a smaller output spot, which is desirable in many Top-Hat applications.

The two translation stages shown in Fig. 2 allow precise control of element positions to reduce tolerance effects. This is discussed further in the section on tolerances.

As mentioned regarding the spatial filter aperture, all apertures in the beam path should be at least twice as large as the beam size (1/e²) at the aperture plane (preferably over 2.5×). These typically include mirrors (for beam folding), beam expanders, beam splitters, and filters/diaphragms.

All optics in the beam path should be of high quality, with low surface figure irregularity, to avoid introducing wave-front errors that would degrade Top-Hat performance. Mirrors should have high flatness specifications; a larger incident beam size reduces sensitivity to aberrations.

The Top-Hat element requires a collimated input beam. For stability and performance, it is recommended to place the Top-Hat element near the laser waist. If the beam has a small divergence angle (<1°), this placement primarily affects the exact working distance rather than output quality.

If the DOE must be located away from the beam waist due to mechanical or other constraints, this distance, along with the beam divergence, must be considered in the DOE design. Otherwise, wave-front aberrations can produce interference or ripple patterns in the output beam, with intensity increasing as a function of the DOE’s distance from the waist and the beam divergence angle.

When designing the desired Top-Hat output size, it is important to understand the physical limits of the minimum spot size. The diffraction-limited spot size is given by:

Where:

- L: Working distance

- λ: Wavelength

- D: Input beam size

- M²: M² value of the input laser beam

As a rule of thumb, the minimum Top-Hat spot size will be 3–5 times the diffraction-limited spot size given by the above mentioned formula. The exact factor depends on whether the element is a conventional Top-Hat or a Stable Top-Hat.

Characteristics

- Uniform intensity profile: Typically ±5%.

- Steep transition region: Typically similar to a diffraction-limited spot with the same input diameter and working distance.

- High power threshold

- High efficiency: >95%

- Sensitivity to X–Y displacement: ≤5% of the input beam to maintain acceptable performance.

- Sensitivity to input beam diameter: ≤5% of the input beam to maintain acceptable performance.

- Rotation insensitive: For round shapes.

- Sensitivity to working distance: ≤50% of the spot size to maintain acceptable performance.

Sensitivity to Alignment and Beam Tolerances

Top-Hat elements are sensitive to various parameter tolerances (see the section Characteristics). When designing a setup that includes a DOE, it is important to ensure control and stability of these system parameters.

As depicted in the typical setup in Fig. 2, accurate translation stages, high-quality laser beams, spatial filters, and beam expanders all contribute to the stability of the optical system.

Many Top-Hat output specifications depend on the relative displacement or mismatch of the input beam diameter. The system can be made less sensitive by expanding the input beam prior to the DOE. For example, for a 10 mm input beam, a 5% mismatch corresponds to 0.5 mm tolerance, whereas for a 2 mm beam, the same 5% tolerance corresponds to only 0.1 mm.

Tolerances on the Top-Hat Profile

Simulated Effects

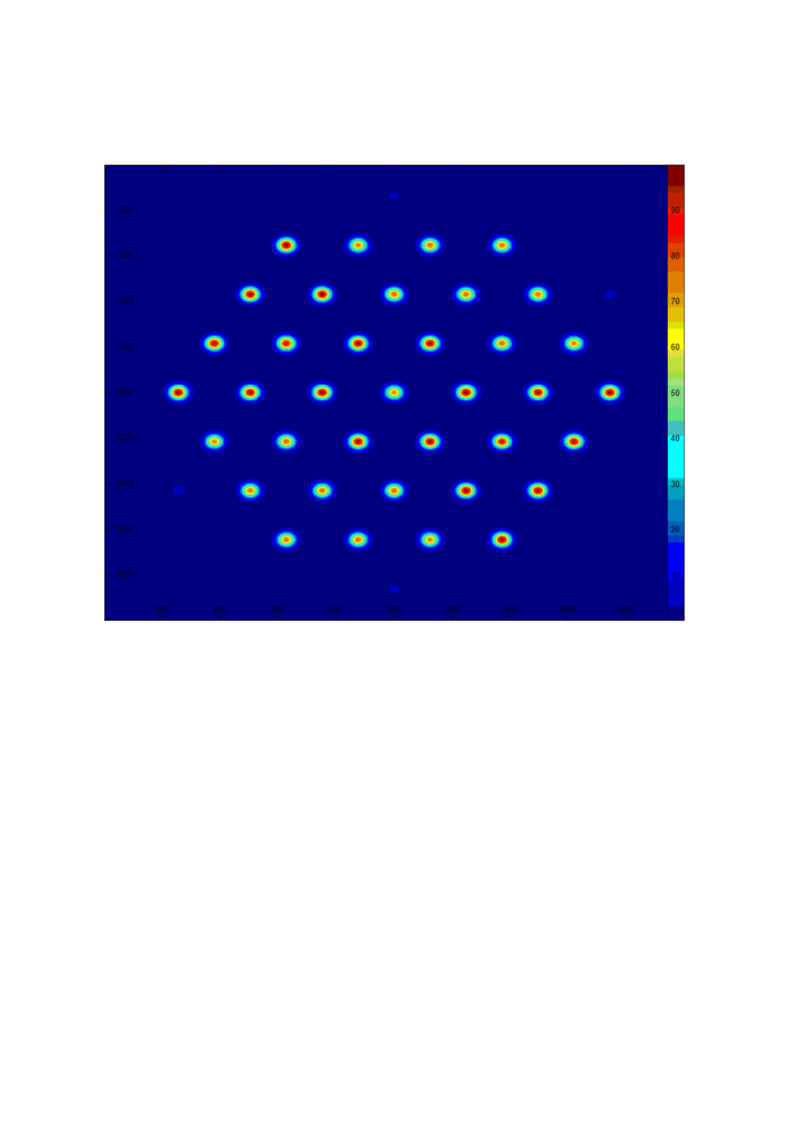

The best performance is achieved when the Top-Hat element is precisely positioned and perfectly aligned in the plane of the nominal working distance. To illustrate the sensitivity of Top-Hat performance to different tolerance parameters, several graphs are included for a standard Top-Hat element (Working Distance: 120 mm, Wavelength: 532 nm, Input Beam Diameter: 10 mm).

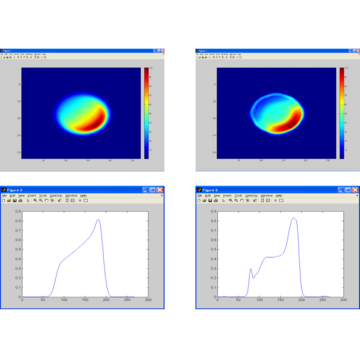

Noteworthy in Fig. 3 is the “tilted” Top-Hat profile caused by beam decentering; that is, the intensity exhibits a slope from one side of the spot to the other.

Note the different behavior of the Top-Hat profile when the element is positioned too close (red curve) versus too far (green curve). In both cases, uniformity decreases, while excessive working distance produces narrow peaks at the spot periphery (often referred to as “dog ears”).

Figure 5 shows a behavior very similar to that observed in Fig. 4. There is a clear parallel between using an input beam that is larger than the design specification and operating with excessive working distance. In both situations, the Top-Hat profile exhibits reduced uniformity and pronounced peripheral peaks (“dog ears”).

Stable Top Hat Designs

As shown above, traditional Top-Hat elements transform a well-defined Gaussian beam into a uniform spot at a specific work plane, but their performance is often sensitive to the input beam’s position, orientation, and quality. The Stable-Top design family addresses these limitations by providing similar uniform-intensity performance while being significantly less sensitive to variations in the input beam. The following points highlight key differences between Stable-Top and standard Top-Hat designs.

Characteristics

Compared to the traditional Top-Hat approach, the Stable-Top offers the following advantages:

- Less sensitive to X–Y misalignment

- Less sensitive to ellipticity of the input beam

- Less sensitive to the beam quality (M²) of the input beam

- Less sensitive to the input beam orientation

- Sharper edge definition

However, the following drawbacks may be observed:

- Stronger side lobes

- Larger ripple in the center of the spot

Comparison of Simulation (Nominal)

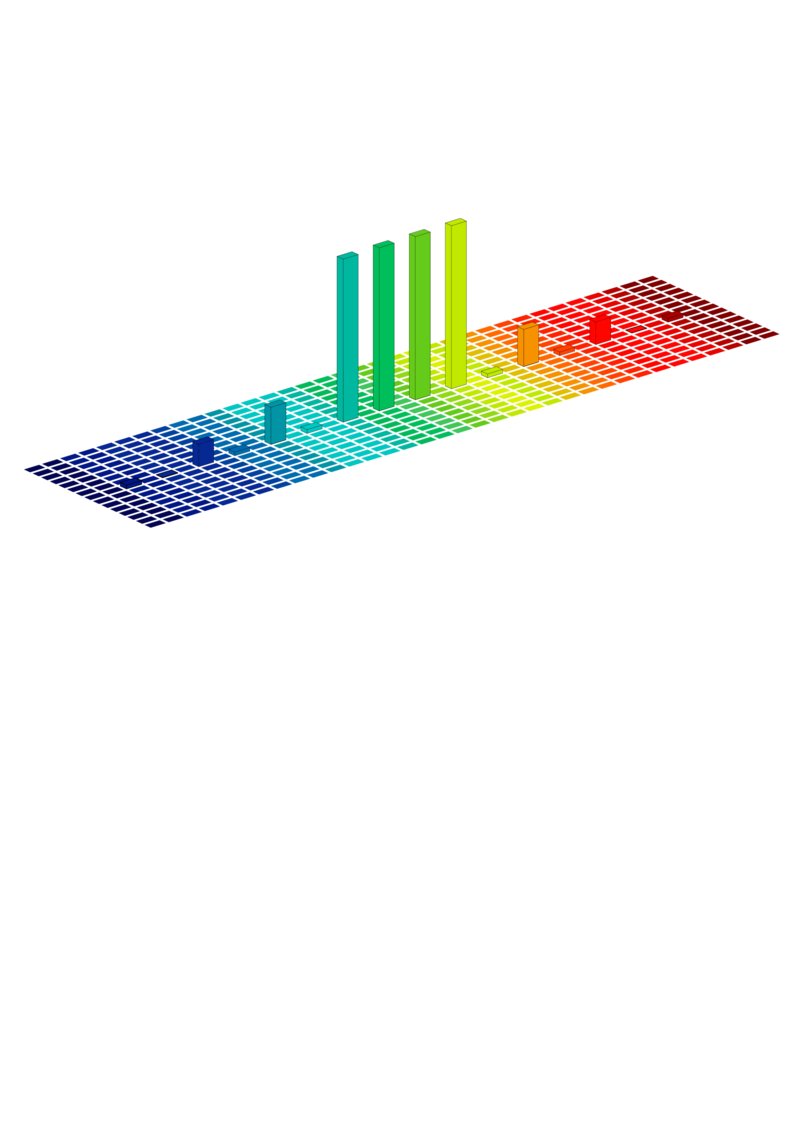

For a specific design, we found the transition region to be approximately two times smaller for the Stable-Top design (defined as the region in which the spot intensity rises from 14% to 90% of the maximum). Although this value may vary between designs, it is expected to be representative of this design family.

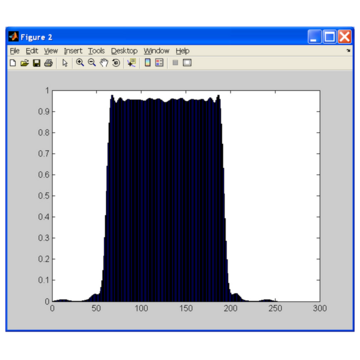

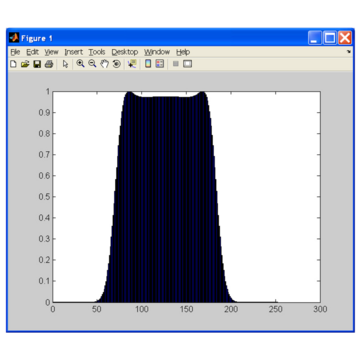

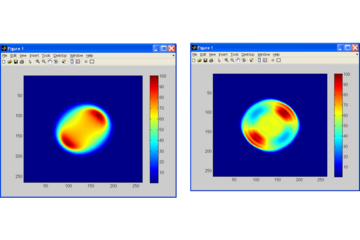

Unlike the traditional Top-Hat, which in theory can achieve a virtual ripple-free intensity profile, the Stable-Top will always exhibit a small theoretical ripple in its uniformity, as shown in Fig. 5.

A cross-section of the intensity profile (Fig. 6) shows that the ripple for this design is very small (approximately 2% in our case), and its shape is relatively irregular. This characteristic shape helps compensate for various types of misalignment.

Comparing the profile with that of the traditional Top-Hat (Fig. 7), we see that the overall uniformity is about the same. However, the traditional design exhibits virtually no side lobes but has a larger transition region.

Fig. 8. Simulated sensitivity to misalignment for the Traditional Top-Hat and Stable-Top designs. The example shows the effect of a 0.5 mm displacement of the beam in both the X and Y directions, relative to a 6 mm beam diameter.

Figure 9 demonstrates that the new Stable-Top design maintains a profile close to the intended circular shape, even when the input beam is elliptical and rotated by 45° relative to the optical axis.

Comparison of the Traditional Top-Hat and Stable-Top designs showing their sensitivity to non-circular input beams

Contact Our Experts

For further advice

Product Selection

LASER COMPONENTS UK - Your competent partner for optical and optoelectronic components in the United Kingdom.

Welcome to LASER COMPONENTS UK Ltd., your expert for photonics components. Each product in our wide range of detectors, laser diodes, laser modules, optics, fiber optics, and more is worth every Pound (£/GBP). Our customized solutions cover all conceivable areas of application: from sensor technology to medical technology. You can reach us here:

4 William House, Old St Michaels Drive

Braintree CM7 2AA

United Kingdom

Phone: +44 1245 491 499

Email: info(at)