APD Selection Guide - Si or InGaAs

Choosing the Right APD Material

for Laser Range Finding

In Laser Range Finder (LRF) design, the right combination of Pulsed Laser Diodes (PLDs) and Avalanche Photodiodes (APDs) can enhance range, accuracy, battery life and overall cost.

The detector material of the APD has great i nfluence on range measurement reliability. Depending on the demands for maximal range, resolution and eye-safety, designers have the choice between III-V compounds such as InGaAs- or Silicon-based APDs – both with their distinctive set of advantages and disadvantages. Of course, these must be coupled to the appropriate l asing wavelength of PLDs, typically 905 nm for Silicon and 1550 nm for InGaAs.

This issue of our LRF Guides will provide high-level guidance on how to choose the best standard APDs and when to consider a customized solution.

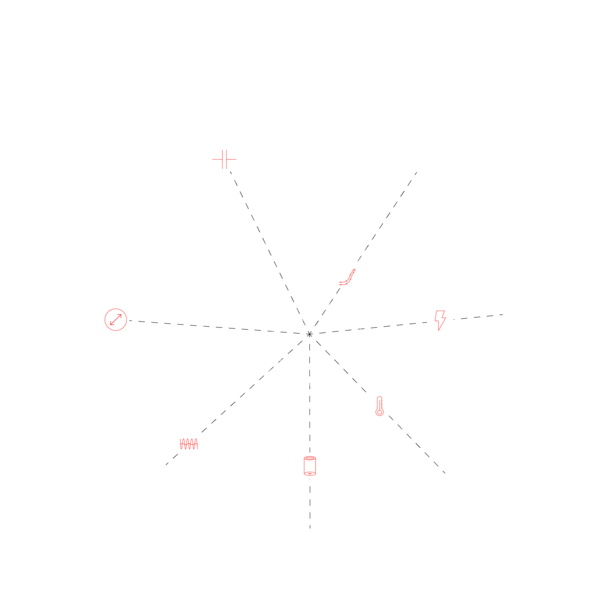

APD Interdependencies

Choosing the right APD for LRF is a complex issue. There are many parameters that have to be considered – such as wavelength, active area, capacitance, rise time, dark current, temperature and packaging.

The challenge is that you cannot change one without affecting the others. As you can see below, they all create a complex web of interdependencies.

Your goal must always be to find the right balance that will provide the best value for one desired key factor without having to accept significant losses elsewhere.

System Parameters and Design Considerations

Wavelength

Depending on system requirements and environmental conditions, laser range finding applications mostly use emitters at two wavelengths.

- 905 nm is widely used in industrial and consumer applications.

It offers good range accuracy and lower overall system costs by using Silicon APDs. - 1550 nm is the preferred wavelength for military, defense, and higher-end surveying equipment. It offers a longer operating range than 905 nm and eye safety at all power levels. In addition to this, 1550 nm systems typically also feature reduced sensitivity to solar background noise, and increased penetration through atmospheric conditions such as fog, rain and dust.

It is obvious that the APDs’ responsivity spectrum must match the wavelengths of the Pulsed Laser Diodes, PLD.

905 nm - Low Dark Current vs. High Sensitivity

Silicon APDs cover a broad spectral response range from UV to the near infrared and allow for great flexibility in system design (NIR). Thanks to their low dark current levels and potential to reach very high amplification gains they offer a high signal-to-noise ratio (SNR) which enhances sensitivity and accuracy in in low-light conditions, even single-photon counting.

On the other hand, they are sensitive to solar background illumination and while they can reach higher gains of operation than InGaAs APDs, they also will amplify said background signal. I ncreasing the launched power of the laser source would pose a risk of exceeding eye-safety limits. Consideration of InGaAs APDs therefore remains a valid option.

1550 nm - InGaAs For any kind of Weather

InGaAs APDs are specifically optimized for operation in the infrared region, typically between 900 nm and 1700 nm, while Si APDs do not respond to light beyond 1100 nm. Therefore, InGaAs is considered the obvious choice for 1550 nm systems – especially in scenarios that require detecting weak signals or long-range measurements. Their reduced sensitivity to visible solar background illumination leads to enhanced performance in outdoor environments with significant sunlight, while they also offer good penetration through fog, rain, and dust.

»905 nm AND 1550 nm are the most common wavelengths in laser range finding – each has its specific benefits.«

Arshey Patadia

Product Manager Si & InGaAs Avalanche Photodiodes

Further Considerations

Active Area

The Active Area of a photodiode impacts its ability to collect and process light. When choosing an APD for range finding, one always must consider its interdependence with the component’s capacitance and other characteristics, such as dark and noise current.

In general, Silicon APDs can offer a much larger active area that enhances the overall sensitivity and allows for the detection of weaker return signals. This provides greater measurement accuracy, especially at a longer range, and wider field of view (FoV). However, the active area also increases capacitance, which in turn increases noise in the first-stage electrical amplification circuitry and slows down the response time of the APD. Larger surface areas also introduce larger leakage currents and therefore negatively affect SNR. In contrast, the typically smaller active areas InGaAs APDs result in lower capacitance, faster response times and higher bandwidth.

Therefore, these photodiodes are better suited for applications requiring rapid detection and measurement of laser pulses, but their much smaller size does add complexity to alignment of optics to focus the return signal correctly.

Dark and Noise Currents

Dark current in APDs refers to the flow of current in the absence of incident light. It contributes to the general background noise, reduces the SNR of the APD and has an impact on its sensitivity and performance in low-light conditions.

However, dark current levels can vary between different APD variants and manufacturing processes, and it is therefore essential to consider the specific dark current specifications of each APD model as well as the number of expected received photons for the application and its desired level of performance.

Beyond dark current, the internal avalanche phenomenon itself generates noise that is a function of the gain level and quality of the APD.

Typically, Silicon APDs offer a lower noise amplification and thus can reach higher usable gains, when compared to InGaAs APDs. Given the higher background solar illumination and its amplification by Silicon APDs, range-finding using InGaAs can often still reach longer ranges.

Capacitance

Capacitance refers to the ability of a device to store electrical charge. In APDs, capacitance arises from the structure and design of the device, including the thickness of the depletion region and the associated junction capacitance. The capacitance of an APD affects its ability to respond quickly to changes in incident light intensity, which is crucial for accurate laser range finding.

Silicon APDs, being an indirect material and thus requiring much thicker junctions, therefore typically exhibit lower junction capacitance compared to InGaAs APDs, which is a direct bandgap material and thus much thinner layers suffice to absorb light fully, which allows for faster response times and reduced signal distortion. Still, the interdependency between the active area and capacitance must be considered and both factors balanced.

Rise Time

An APD’s rise time refers to the time it takes for the output signal to respond to a change in the incident light intensity.

Rise time can be slowed down by high capacitance, lower bias voltage or longer wavelengths. It is therefore important to strike a balance between those factors. While low capacitance is preferred to achieve faster rise times, it is essential to ensure that the APD still maintains sufficient sensitivity and signal-to-noise ratio (SNR) for accurate distance measurements

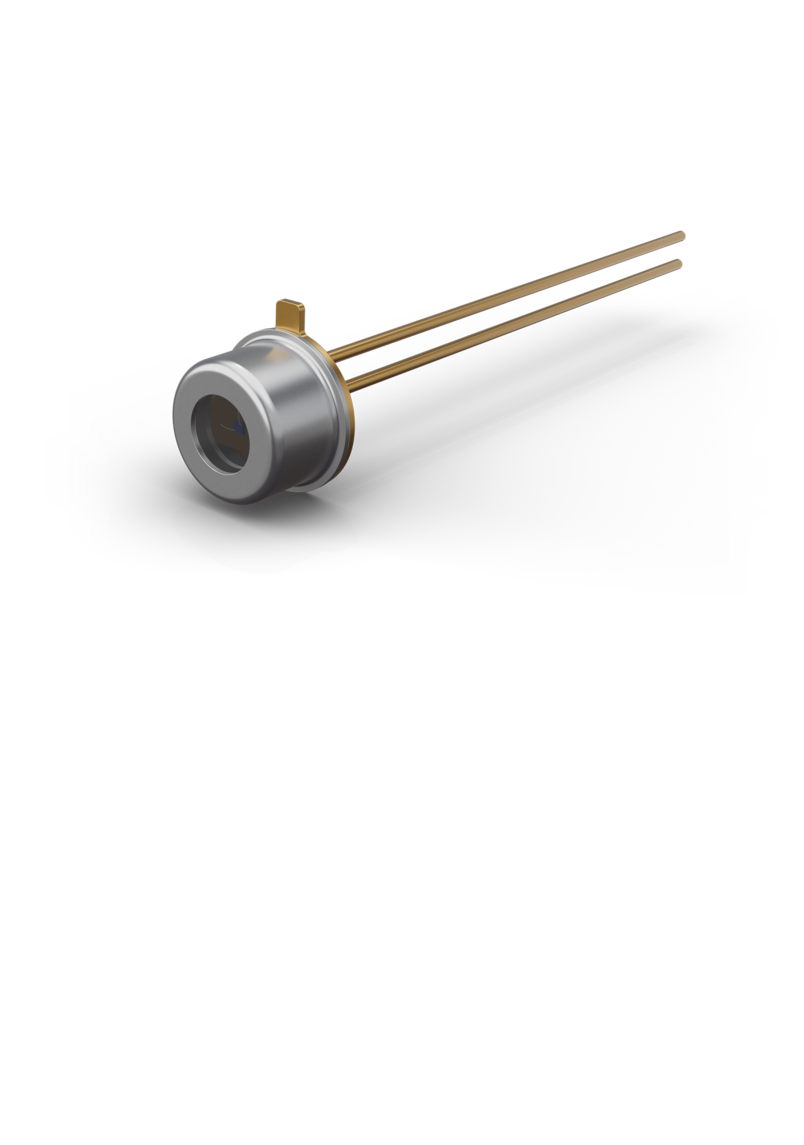

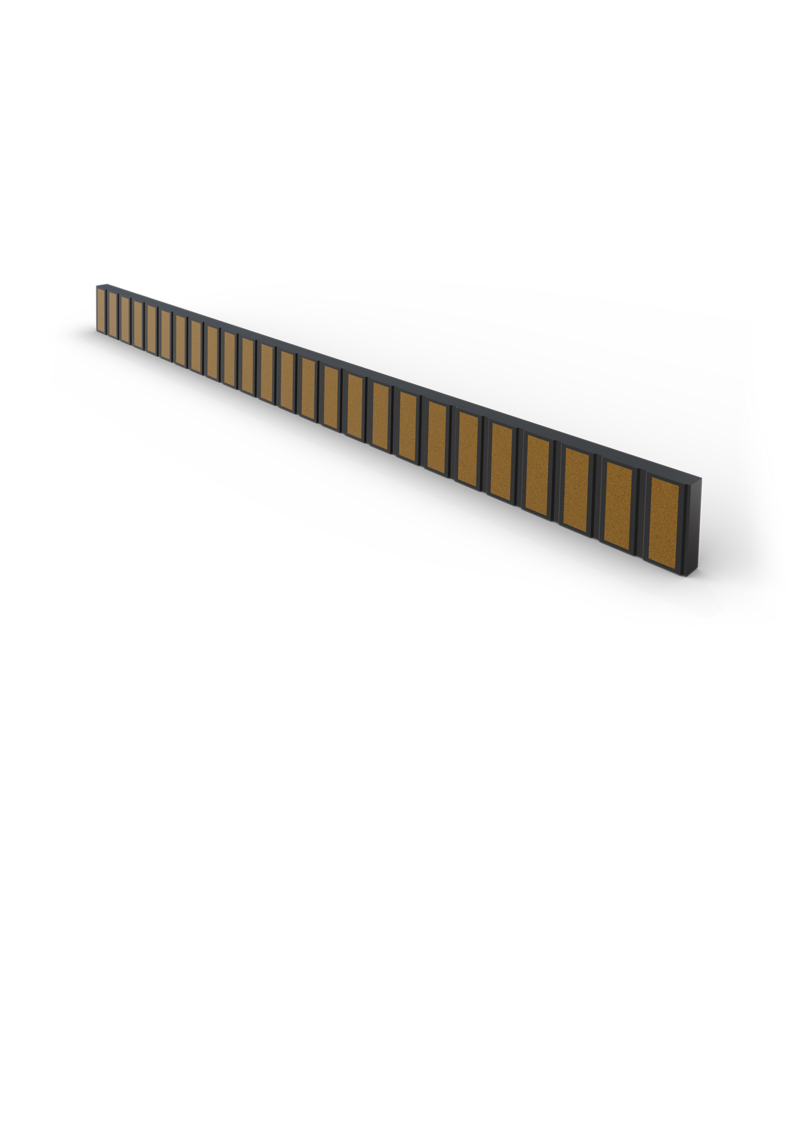

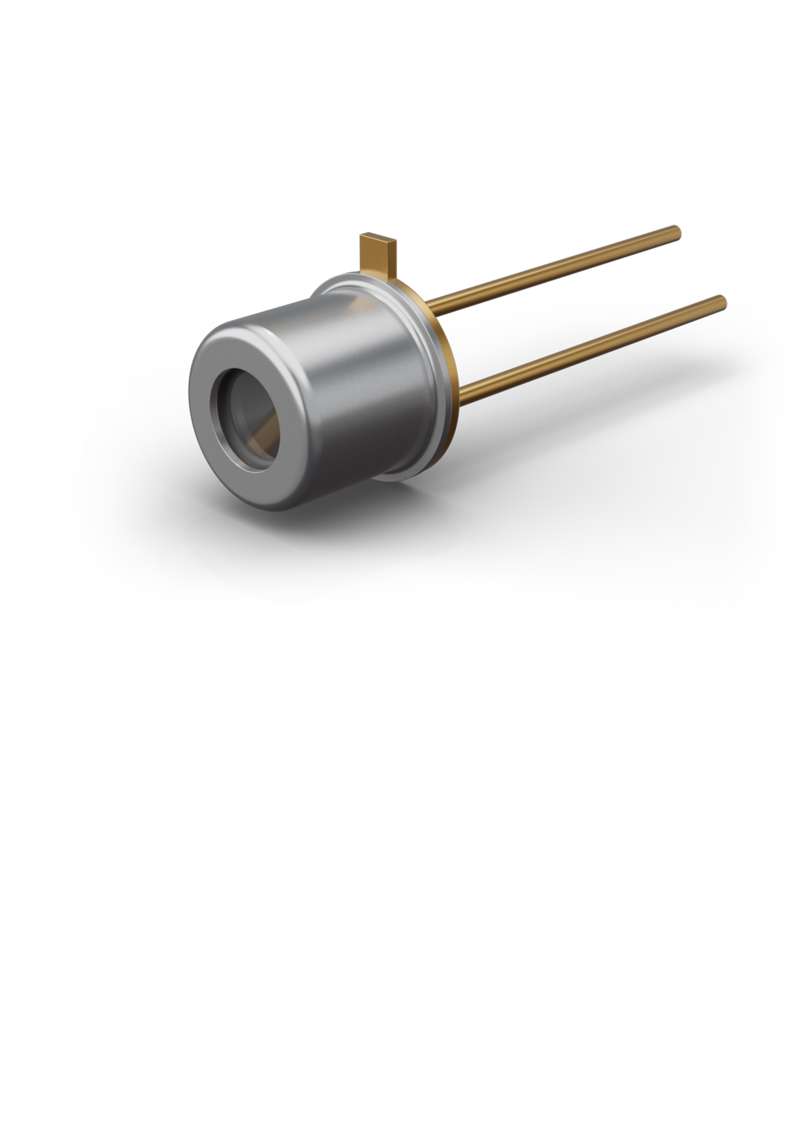

Packaging

Packaging designs for APDs differ widely and are mostly determined by the requirements of specific applications. Options range from the classical Transistor Outline-cans (TO) and Surface Mounted Devices (SMD) to fiber-pigtailed solutions, devices with lenses to increase the field of view, and integrated passband filters tuned to specific applications and light sources. It is therefore difficult to state any general differences between Silicon and InGaAs packaging technology.

Operating Temperature

Designers of Silicon and InGaAs APDs must consider the operating temperature conditions of their systems. First, the nominal operating voltage to reach a certain gain will vary as a function of temperature at different rates for different material thicknesses, typically larger shifts for Silicon than InGaAs as the active material is thicker.

Dark and noise currents also increase for higher temperatures, and inversely at colder temperatures typically by a factor of two for every 8-10 degrees Celsius. Consequently, in some applications, it is worthwhile to integrate a thermoelectric cooler (TEC) or a heater to stabilize the operating temperature and thus simplify the control loop needed to maintain a stable gain over the range of operating temperatures, even at a higher cost.

Furthermore, the quantum efficiency (Q.E.) and responsivity spectrum shifts towards shorter wavelengths at colder temperatures, which can render a Silicon APD almost non-responsive at cold temperatures around the Nd:YAG wavelength (1064 nm). Some trade-offs are possible to have a quasi-athermal response with a lower operating gain over a certain temperature range, which can further reduce the complexity of the electronics. There is also a potential risk of having no remaining dynamic range if the breakdown voltage reaches the reach-through voltage at cold temperatures. It is, therefore, crucial to choose the proper options, packaging, and design suitable control electronics to meet the requirements of your application in the expected environmental operating conditions.

Costs

Cost is a major driver towards Silicon APDs. They can be processed on larger wafers, using well-established lithography, metallization, and diffusion processes. Being a well-established technology, they offer lower per APD cost and better economies of scale. InGaAs APDs on the other hand require more complex epitaxial-growth techniques on smaller wafers, further adding to their unit cost.

REquest your personal offer now.

LASER COMPONENTS Germany GmbH

Free Download

You just read the chapter "Si or InGaAs? - Choosing the Right APD Material for Laser Range Finding". Click on the button below to download the text as PDF (English version only).

Product Selection

for laser range finding

Click here

LASER COMPONENTS Germany - Your competent partner for optical and optoelectronic components in Germany.

Welcome to LASER COMPONENTS Germany GmbH, your expert for photonics components. Each product in our wide range of detectors, laser diodes, laser modules, optics, fiber optics, and more is worth every Euro (€/EUR). Our customized solutions cover all conceivable areas of application: from sensor technology to medical technology. You can reach us here:

Werner-von-Siemens-Str. 15

82140 Olching

Deutschland

Phone: +49 8142 2864-0

Email: info(at)