Standard and Customized Dichroic mirrors

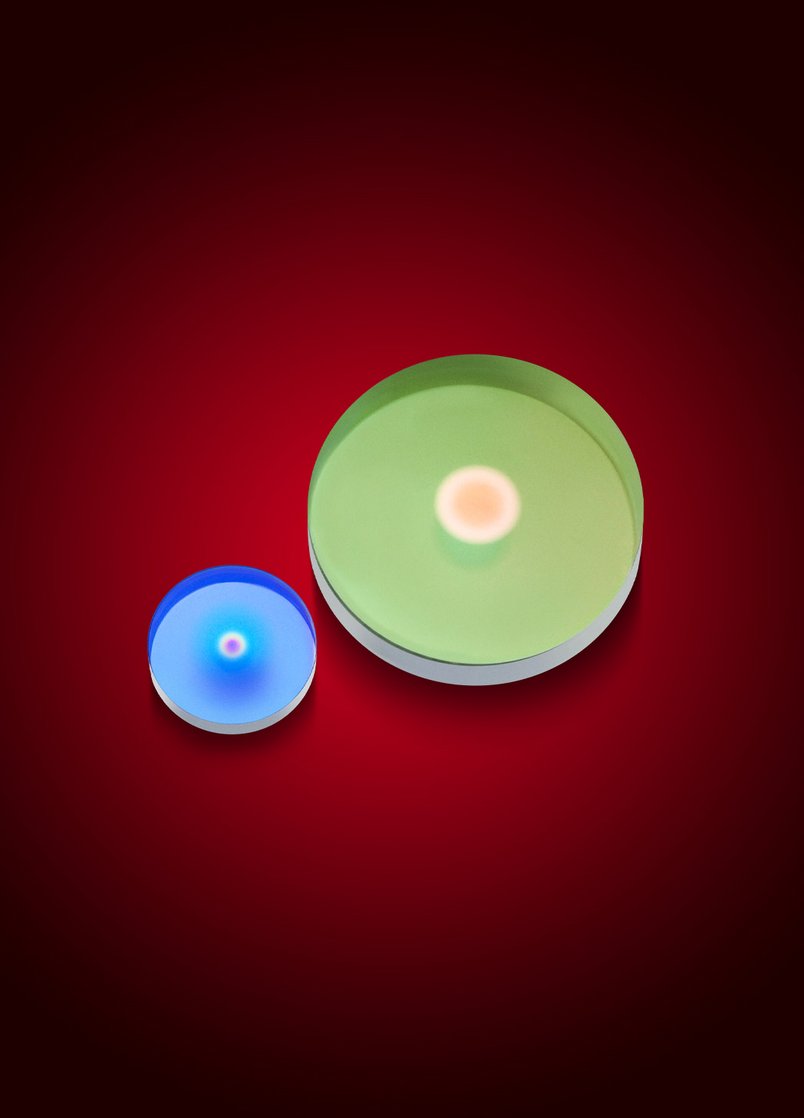

Dichroic mirrors are used to combine beams or to split two beams that have different wavelengths.

With a long-pass mirror, the long wavelengths are transmitted while the short ones are reflected. Short-pass mirrors allow the short wavelengths to pass and reflect the long ones.

On request, we also develop complex coating designs with multiple transmission and reflection ranges. Such optics are used e.g. in modern laser material processing, where the working plane is observed in different spectral ranges.

Follow these “golden rules” to find the best mirror design for your application:

- Bandwidth:

The bandwidth for the reflected part of the beam is limited. For the best possible beam separation or combination, it is important to allow a wavelength range to be transmitted and individual wavelengths to be reflected.

Examples: HR1064HT400-700;HR355HT532+1064

- Polarization:

The absolute degree of reflection is higher for s-polarized light than it is for p-polarized light. The opposite relation applies for transmissions. Therefore, keep the polarizations in mind when planning your assembly.

- Reflection better than transmission:

The efficiency is higher for the reflected beam. If your application requires high efficiency at a certain wavelength, you should take this into account when selecting the mirror.

- Beam combination of SHG, THG, ...:

Reflection peaks occur at λ/2, λ/3, etc. of the reflected wavelength. In this case, you should prefer a long-pass coating - i.e. an HR355HT532+1064 coating rather than an HR1064+532HT355 coating.

Contact

Benefits

- Conçu sur mesure pour votre application

- Simplifie votre conception visuelle

Features

- Wavelength range 248nm - 3000nm

- Different specifications upon request

Datasheets

More Information

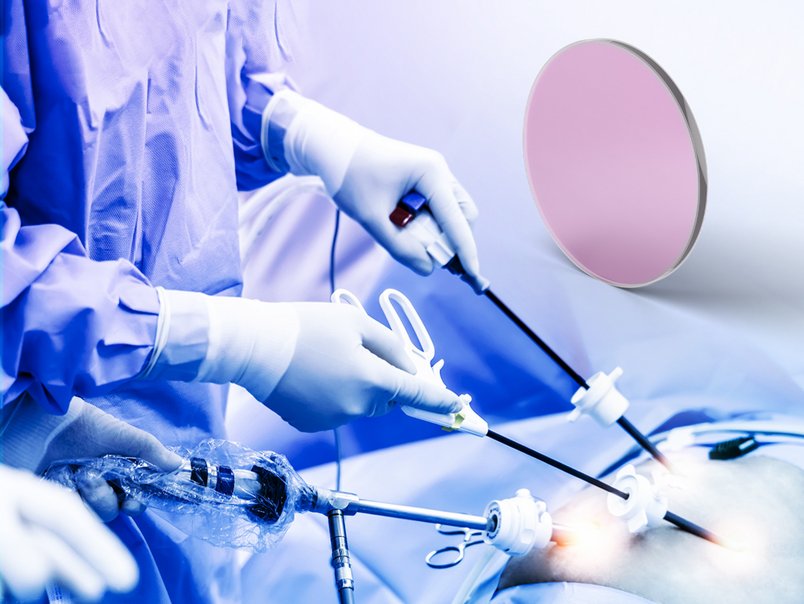

Customized Dichroic Mirrors

For PRocesS Control

We also provide customized dichroic mirrors that are suitable for you individual application.

Especially for monitoring applications there is a variety of functions in a dichroic mirror.

Example

In a typcial monitoring application dichroic mirrors are needed for bending of the laser wihich is used for the material processing. At the same time a part of the pilot laser for positioning needs to be reflected for positioning of the workpiece in the working area.

Additionally for process control purposes the optics has to tansmit the visible range and light in the NIR above the laser wavelength.

As an additional feature also special measuring systems like OCT (optical coherence tomography) for depth measurement at a wavelength close to the high-power laser wavelength will be transmitted.

Click here

Accessories

Beyond Borders

Our conversion screens make your laser visible in the range from 250-600 nm, 700-1700 nm, and 1.5 20 µm.

News & Events

Laser Optics