To get the most out of the laser module’s optical properties and eliminate the laser position’s thermal drift even with limited mounting space, see below:

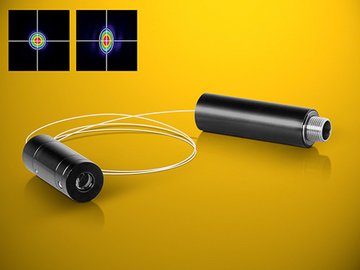

We detached the laser unit (including control electronics) from the beam-shaping optics in our new FLEXPOINT® MV fiber laser modules; both mechanical components are connected via a single-mode fiber.

The housings of the FLH optic head and FCL laser source are shorter than conventional laser modules. Because they can be installed separately, the laser head also fits into systems with limited mounting space.

This separation also has thermal advantages; the thermal drift of the laser beam is almost completely eliminated.

This also improves the optical properties: The use of a singlemode fiber leads to less scattered light in laser projection and also prevents side modes. A comparison of the beam profile with and without fibers is shown in the figure below.

The FP-FCL laser source and FP-FLH optic head can be ordered separately: this ensures maximum flexibility in selecting the right system. Both components are designed for use with FC/PC connectors.

For introduction onto the market, lasers will be offered at 450 nm and 660 nm with an optical power of up to 50 mW. Other wavelengths and optical output power levels are available upon request. The laser is driven by microprocessor-controlled electronics, the serial interface of which is used to program and readout the laser.

The FP-FLH optic head can be equipped with different beam profiles: this includes homogeneous lines, lines with a Gaussian distribution, dot projections, and more than 60 different DOE optics that produce parallel lines, dot matrices, circles, or the like.