During material processing, the beam profile of the laser in the working plane is crucial to the quality of the end results. By selectively changing the profile, improvements in the process can be made. The following options are available:

- Top Hat Shapers

- Stable Top Beam Shapers

- M-Shapers for Scanner Applications

- Homogenizers/Diffusers

- Elliptical Diffusers

- Vortex-Lenses

- Diffractive Axicon

- DOEs for Structured Light

- Elongated Focus Module (DeepCleave)

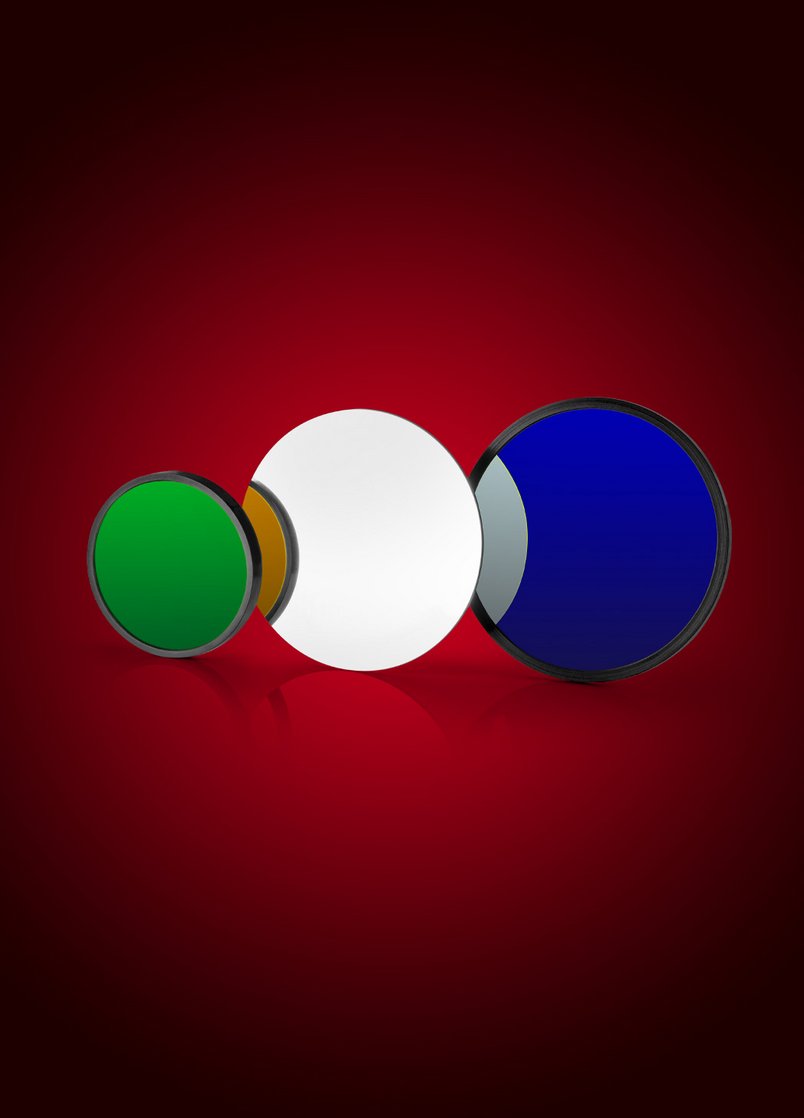

Top Hat Beam Shapers

A Top Hat DOE produces a so-called Top Hat beam profile in the working plane with a steep slope from a Gaussian-shaped beam. The beam profile can have almost any type of cross section, round or square are the most popular.

Stable Top Beam Shapers

The Stable Top element has the same function as a Top Hat element. However, the optimized design allows for larger tolerances of the incident beam (quality, size, and position). Small sidebands and narrow fluctuations in intensity can be observed in the center of the beam profile.

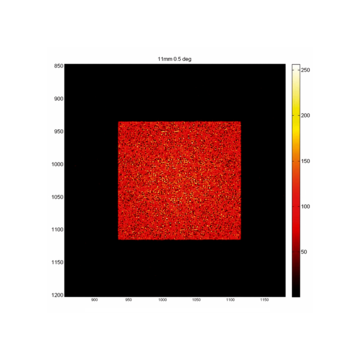

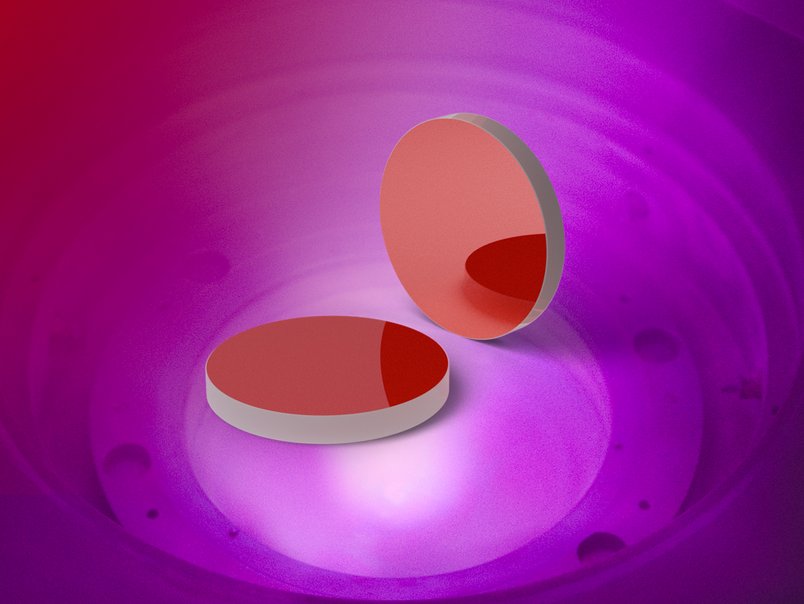

Homogenizers/Diffusers

Homogenizers – also known as diffusers – smoothen the cross section.

These elements are commonly used in medical applications such as hair or tattoo removal. In such applications, it is crucial to avoid hot spots to prevent the burning of skin.

Elliptical Diffusers

Elliptical diffusers function similar to homogenizers. The beam components perpendicularly stacked on top of one another have different fan angles. This results in a homogeneous elliptical beam cross section in the far field.

Vortex Lenses

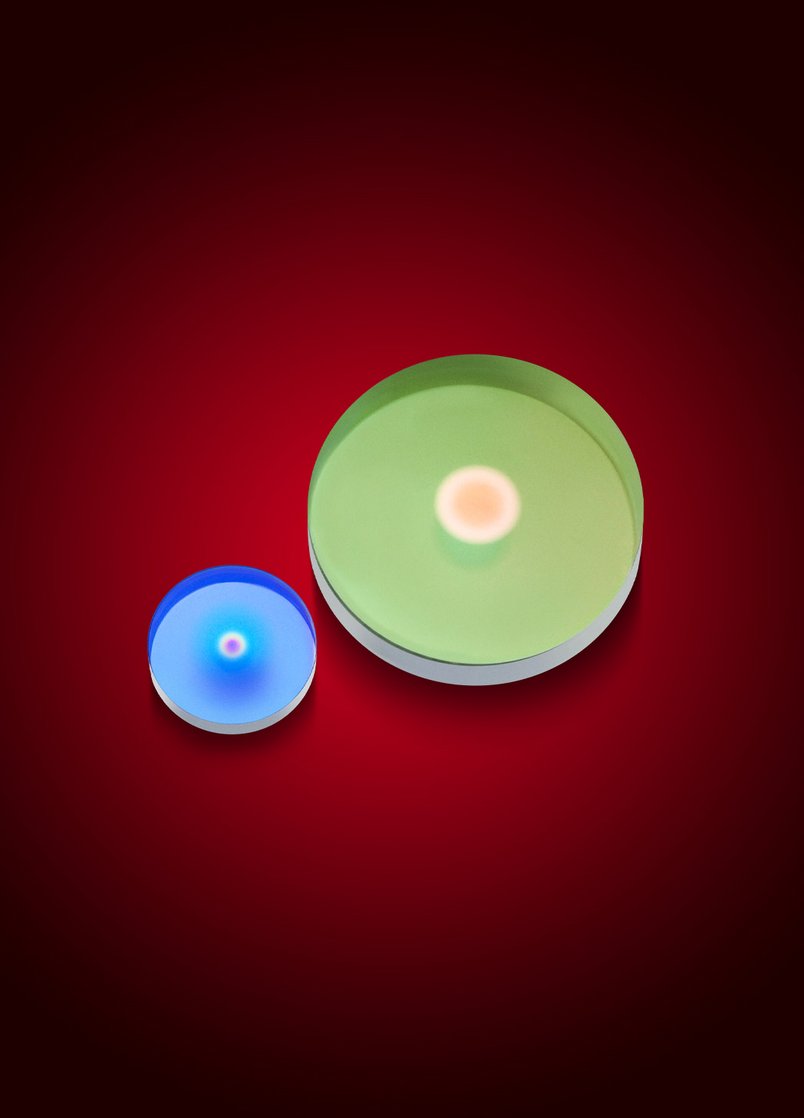

A vortex lens is used to convert a planar wavefront into a helicoid (spiral-shaped) wavefront. Through this rotation, the wavefronts cancel each other out at the center. This transformation occurs through a spiral-shaped structure on a planar substrate.

Diffractive Axicon Elements

These elements shape the laser beam into a ring profile, similar to the vortex element.

The independence from the input beam makes them more advantageous than vortex elements. Diffractive axicons can be used with lasers, the beam quality M² of which is between 1 and 20; M² only affects the ring width.

In addition to simple ring profiles, these DOEs can also be manufactured for use in shaping multiple rings.

It is possible to achieve very small fan angles with DOEs and to work with smaller beam diameters than with a non-diffractive axicon. Another option includes the manufacture of negative axicons.

DOEs for Structured Light

These beam splitting and shaping DOEs offer wide fan angles of up to 80° (at 850 nm). Their emitted light covers particularly large areas. This kind of optics is mainly used in LiDAR applications and machine vision. Depending on the substrate material, they can be used with low laser power in the milliwatt range, as well as with high-power lasers with several kilowatts.

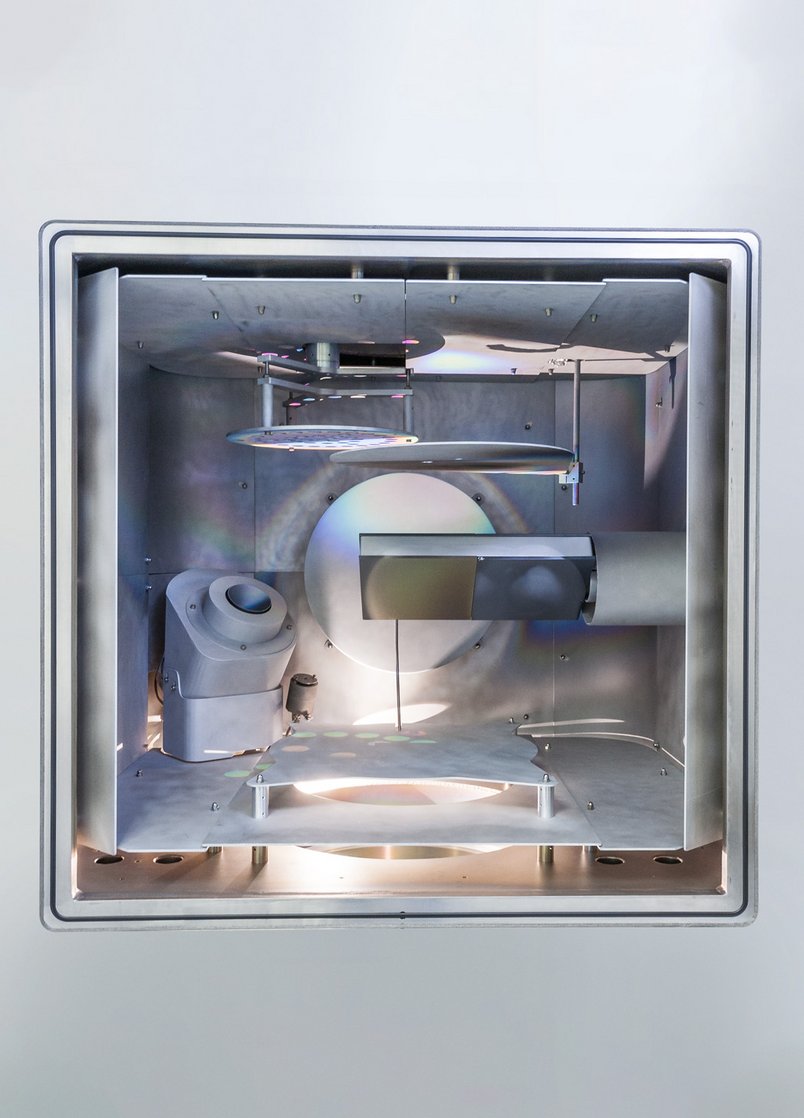

Elongated Focus Module (DeepCleave)

Holo/OR’s DeepCleave module is a complete optical solution for cutting applications in transparent materials, such as flat panels for mobile phones. It focuses an incident single mode laser into a spot with a waist size of approximately 1.8 µm along the entire Depth of Focus range (1-2 mm typical).

Without any additional objectives or other high cost optics, the focused spot reaches the equivalent to 0.35 objective NA. In contrast to Holo/Or's standard elongated focus elements, DeepCleave features a constant intensity distribution along the focus region. It requires low M² and accurate input beam size.

Custom-Made Optics

Using a plane diffractive element, symmetrical and asymmetrical beam profiles can be created.

Micro Lens Arrays

Microlens arrays (MLA) are mostly used to homogenize and shape laser beams - for example, when it comes to coupling the light into a fiber. They consist of numerous micro lenses arranged in a rectangular or hexagonal shape. The MLAs distributed by LASER COMPONENTS are provided with an anti-reflective coating to withstand high laser powers of medical or industrial lasers.

Contact

Downloads

- TopHat - StableTop Beamshaper

- High Power Homogenizer

- Vortex Lens

- Elongated Focus with DOE

- M-Shaper for Scanning DOE

- Utilizing Diffractive Optics - General Overview

- Collimated Beam Shaper

- LeanLineTM Line Generator for Narrow Line Beam Shaping

- Collimated Homogenizer Round Output Shape

- Collimated Homogenizer Square Output Shape

- Broadband Diffuser

- DeepCleave Module

- Micro Lens Array

Click here

News & Events

Laser Optics

LASER COMPONENTS Germany - Your competent partner for optical and optoelectronic components in Germany.

Welcome to LASER COMPONENTS Germany GmbH, your expert for photonics components. Each product in our wide range of detectors, laser diodes, laser modules, optics, fiber optics, and more is worth every Euro (€/EUR). Our customized solutions cover all conceivable areas of application: from sensor technology to medical technology. You can reach us here:

Werner-von-Siemens-Str. 15

82140 Olching

Deutschland

Phone: +49 8142 2864-0

Email: info(at)