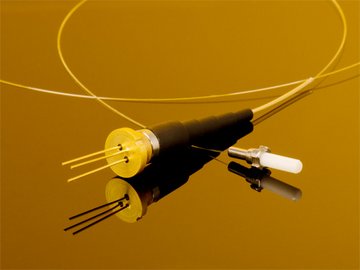

LASER COMPONENTS Canada, Inc. assembles micro-optics, fast axis collimation (FAC) lenses, directly in front of the pulsed laser diode chip. Housed in a TO-46 housing, the beam performance of the laser diode is significantly increased. Based on this technology, pulsed laser diodes with fiber pigtails are manufactured.

With a semi-automatic mounting setup, fibers can be precisely assembled to within just a few µm. This allows coupling efficiencies of > 85% to be achieved. Depending on the laser diode chip and fiber core diameter, peak power levels of > 100 W out of the fiber can be reached.

The reasons for fiber coupling are manifold. In medical or illumination technology, power is required directly at the desired position without any loss caused by additional optics. In laser scanners or in measurement technology, better beam performance is achieved by mixing modes in the fiber. In industry, however, fiber optic technology is used to transmit data across very long distances.

Due to their very robust design these diodes can be used in military applications at temperatures between -40°C and +85°C.

Products. The new pigtailed pulsed laser diodes are available on a standard basis at wavelengths of 905 nm and 1550 nm. The following versions are available:

905 nm pulsed laser diodes

- 13 W from a 105 µm fiber

- 100 W from a 400 µm fiber

1550 nm pulsed laser diodes

- 7 W from a 105/125 µm fiber (NA 0.16)

We not only offer standard versions, but customer-specific versions as well. In fact, our ability to develop inexpensive customer-specific solutions is one of our strengths. Contact us today!