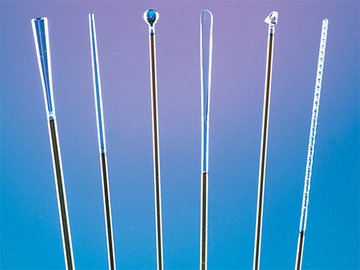

Optical Fibers with Shaped End Surfaces

In optical fiber technology, standard planar and round finishes are commonly used. In certain applications special high-quality finishes are required; thus, it is necessary to find innovative solutions to meet these requirements.

Method. POLYMICRO developed a method of producing individualized fiber end surfaces using a laser. These shaped end surfaces are so-called fiber tips. Laser processing features high reproducibility and does not require the use of an adhesive.

Advantages. When using fibers that have a silica core and doped silica cladding, the cladding remains intact in many designs; thus, the light continues to be reflected at the boundary surface between the core and the cladding.

The majority of fiber tip designs possess rotational symmetry around the fiber axis; however, this is not a necessary requirement. The fiber tips can be adjusted according to the optical properties required in order to meet different application needs.

Varieties. In addition to classical shapes, such as spherical lenses, simple lenses, and tapered-end fibers, diffusers and so-called side-fire fibers can also be produced. The latter two fibers in particular are very commonly used in medical technology.