Fiber Assemblies and Connectors

Information

about fiber assemblies

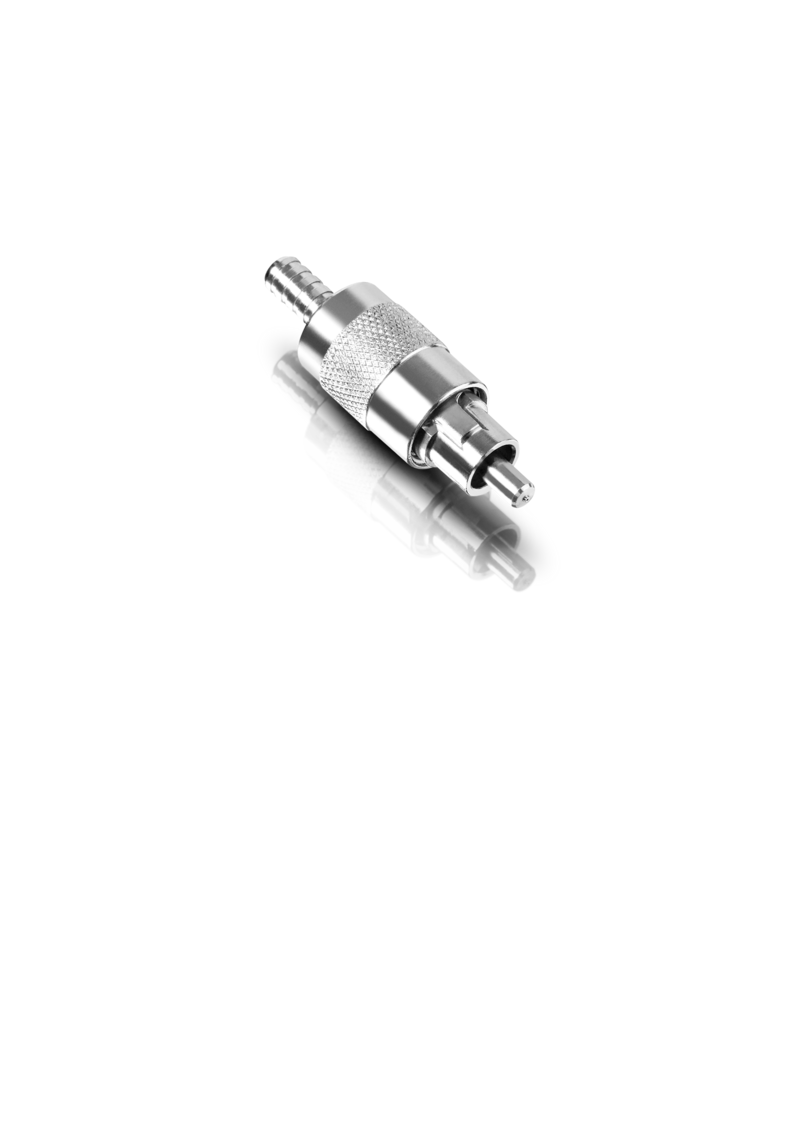

LASER COMPONENTS assembles the widest variety of optical fibers in-house – from bare fibers and industrial fibers to fibers with a protective jacket – all of which can be equipped with all standard connectors. It goes without saying that we also assemble custom connectors with the desired fiber.

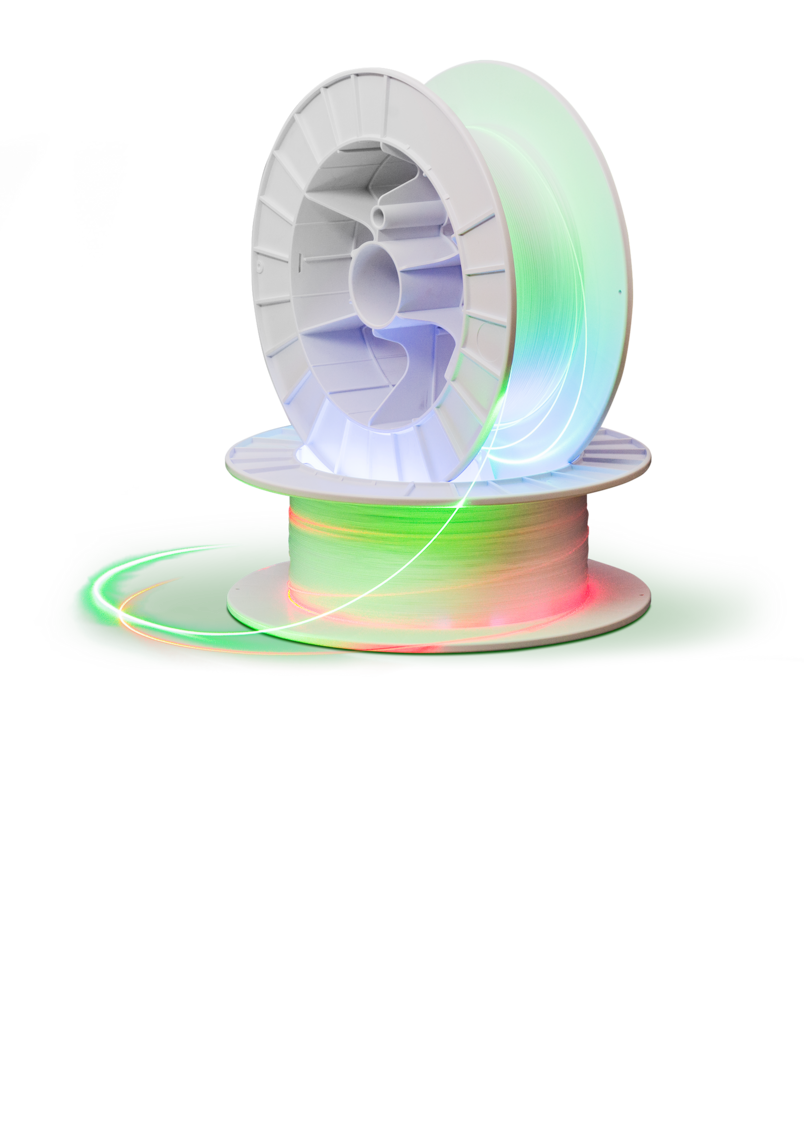

Standard and PM Cables

Custom fiber assemblies are available for conventional applications. Multi-mode, single-mode, and POF cables are available with all standard connectors. We also manufacture reference cables with precise reference connectors for measurement tasks. In addition to standard patchcords, we assemble polarization maintaining cables for telecom, sensor, and laser technology applications, as well as cables with hollow core fibers for the transmission of CO2 lasers.

Coated Fiber Endfaces

An anti reflection coating increases the efficiency of the coupled light beam considerably and reduces back reflection to a minimum. We offer AR coatings for different wavelength ranges. In-house production allows us high flexibility and short delivery times.

Fiber Bundles

Several optical fibers are combined in fiber bundles. You determine the number of fibers to be bundled and the geometric dimensions of the ferrules.

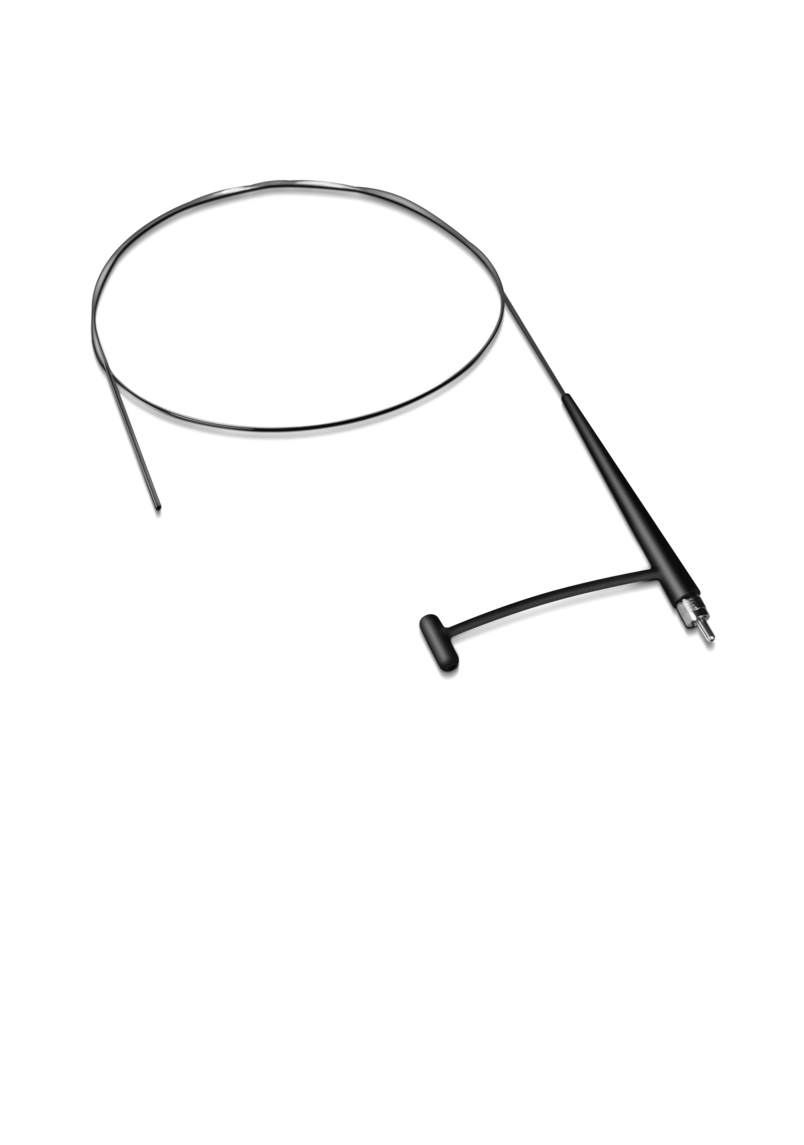

ModeStrip

Our High-Power ModeStrip connector was developed for fiber optic transmission of high optical powers: Cladding modes that are created by a sub optimal beam profile are removed while the generated heat is dissipated via a cooling element. Thus, the High-Power ModeStrip protects both the fiber and connector from thermal destruction.

Fiber Tips

Upon request, we provide the fiber ends with end caps or ball lenses. These so-called FiberTips change the beam characteristics. Cylindrical end caps reduce the power density of the beam, while the light is focused or collimated with spherical lenses.

Customization

Beyond Borders

Your wish is our command: optical fibers according to your requirements will be manufactured at LASER COMPONENTS.

As soon as you determine the properties, we begin production. Length, type of connector, material, and field of application: These are the features that are available for selection in conventional assemblies.

Whether the components are later produced in small or large numbers, we work together with our customers to develop top products.

Product Range

LASER COMPONENTS assembles the widest variety of optical fibers in-house – from bare fibers and industrial fibers to fibers with a protective jacket – all of which can be equipped with all standard connectors. It goes without saying that we also assemble custom connectors with the desired fiber.

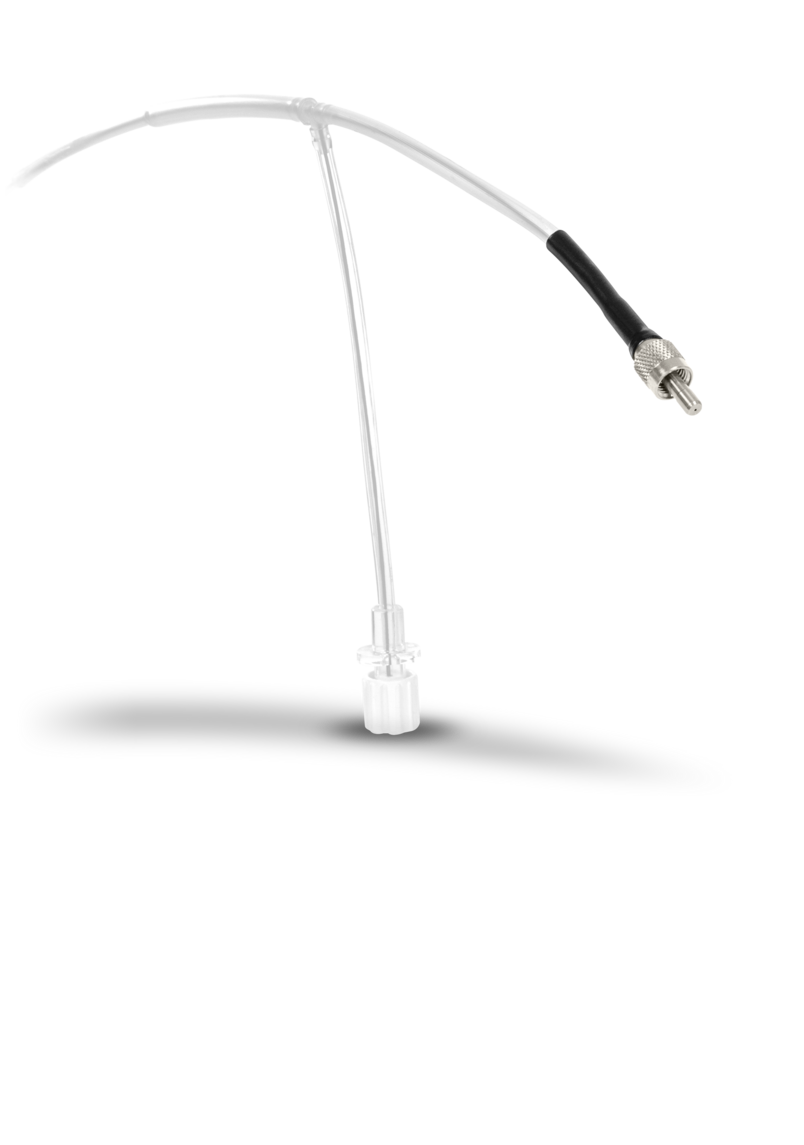

Medical Applications

Moreover, we develop and manufacture fiber-optic components for medical applications; we are certified to do so according to EN ISO 13485. As required, we use biocompatible materials and deliver sterile products upon request. They are manufactured under class 7 cleanroom conditions.

Machinery and Quality Control

We modernize our facilities regularly. Computer-operated cutting and pol-ishing machines work precisely and reproducibly. This is how we achieve high-quality fiber assemblies.

To keep our customers satisfied with our products, we introduced an advanced outgoing goods inspection. With the help of a digital measurement micro-scope, we are able to perform 3D measurements, centricity measurements, and surface analyses for laser and medical fibers.

We have interferometers for fiber-optical connectors available for PC and APC polishing, as well as measurement equipment for insertion loss and return loss testing. We like to ensure that you receive a fiber that has been perfectly assembled and achieves the best results in centricity and laser polishing.

Let us know your needs!

LASER COMPONENTS Germany GmbH

news & Events

Beyond Borders