For Projects Beyond Borders - Together We Make it Whole

Together we make it whole

Beyond Borders

One innovation leads to another: MSG Maschinenbau GmbH relied on the expertise and creativity of LASER COMPONENTS in the development of its new pipe measuring system.

The development of a successful new product is always a joint effort. First comes the company that has an idea and needs components to carry it out. Then comes the product engineer who has an overview of the portfolio and can assess the technical feasibility. And finally come the tinkerers in the development and production departments who take care of the details and turn theoretical considerations into a functioning component. All three complement each other, and the end result is a product innovation like the FLEXPOINT® Radial.

Why Not Measure from the Inside?

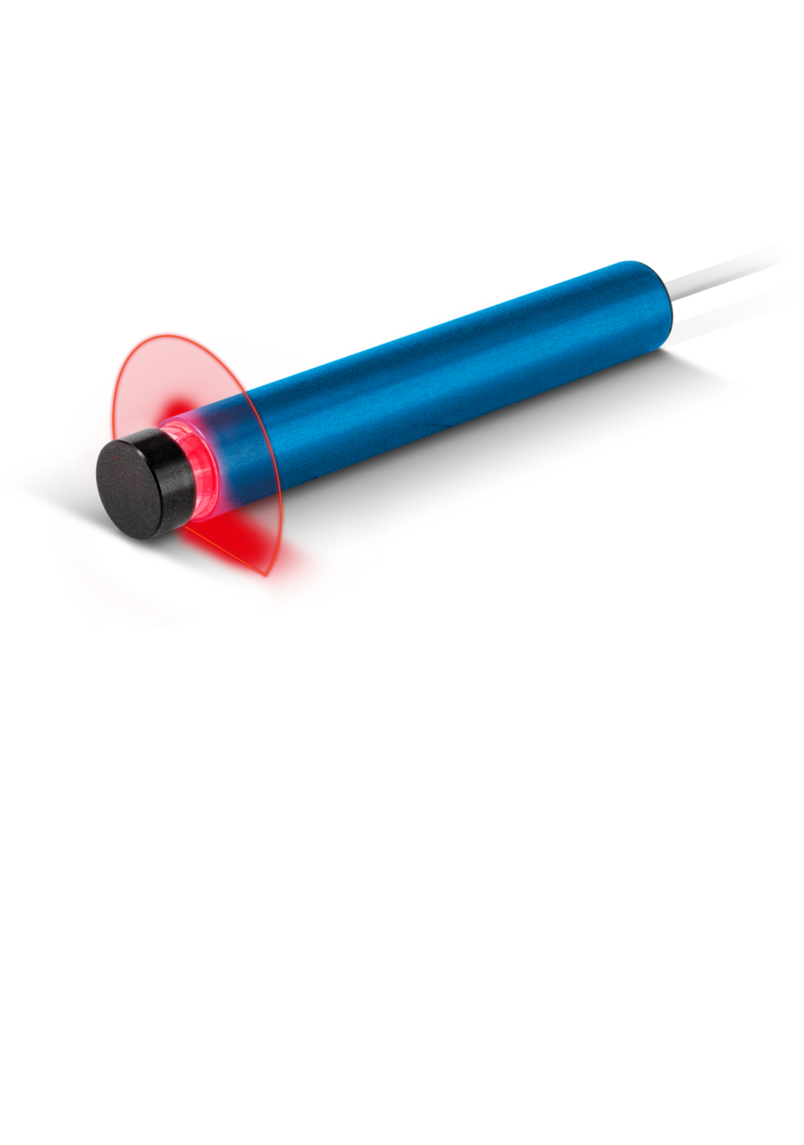

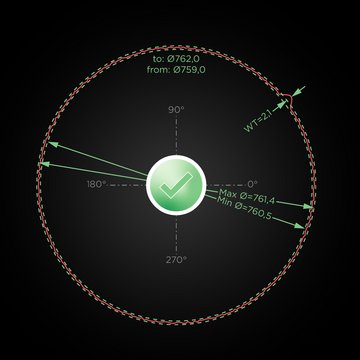

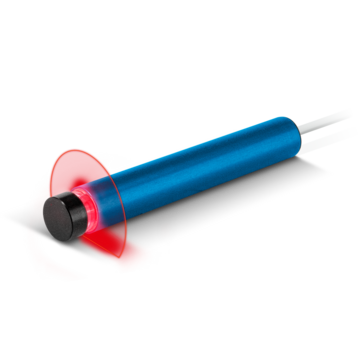

The inspection of pipes begins long before they are buried underground in cities as gas or water lines. Pipes must be as round as possible to later withstand the pressure of earth or water masses. But how can the manufacturer determine that the deviations are within the norm? And preferably in real time, so that they can be corrected during production. Matthias Kramer from MSG Maschinenbau GmbH had an idea: How about a self-calibrating optical measuring system that you can slide into the tube? To achieve this, he needed a laser that projects a homogeneous line across 360° onto the inner surface of a pipe – and preferably without moving parts, to keep the system robust and easy to use.

The Devil Is in the Details

Kramer turned to Stephan Krauß from LASER COMPONENTS. »A ring-shaped laser beam is, of course, a very special product for which there is only a small market,« says the product engineer. »But that is exactly what is so appealing about these types of projects. After all, anyone can do ‘normal laser modules.« The basic principle is simple: a laser beam is directed onto a cone-shaped mirror inside the module so that its light is reflected evenly at an angle of 360°. »As always, the devil is in the details: the laser beam must also be perfectly round and precisely aligned with the cone,« Krauß knows. »Our partners at Blau Optoelektronik have the experience and intuition needed for optimal alignment.«

Picture: Measurement data can be used to create a detailed digital 3D model of the inside of the pipe.

»USING OUR INNOVATIVE ALGORITHMS, WE CAN CREATE HIGHLY ACCURATE SCANS OF THE PIPE’S INTERIOR.«

MATTHIAS KRAMER

Managing partner of MSG Maschinenbau GmbH

Digital Twin

The result of this process is the FLEXPOINT® Radial ring laser module, which enables measurements at an accuracy of 50 µm and yet is flexible enough to adapt power and focus to different materials and tube diameters, for example. Based on the measurement data, a »digital twin« of each tube is created. These virtual models will later facilitate maintenance planning in the digital city of the future, for example.

Picture: 80% homogeneity: »Our measurement system thrives on the line quality of the laser module.«

Click here

Take a deep breath

Beyond Borders

Round-the-clock particle measurements ensure that all road users can stop safely in a tunnel at all times.

To facilitate measurements, PbSe detectors are used to determine the concentration of toxic gases such as carbon monoxide and nitrogen oxides. With a typical wavelength range of 1 µm to 4.7 µm, this detector technology continues to offer the best price-to-performance ratio. In addition, it responds very quickly to even small changes in the level of infrared light and produces a strong signal. Together with our detector plant in Chandler, Arizona, our sales engineers are developing customized solutions to further increase this performance (e.g., by enhancing the sensitivity of the detector up to 5.2 µm through cooling, installing infrared filters for specific wavelengths, and searching for new materials with better thermal conductivity). In addition, LASER COMPONENTS supports the RoHS exemption for PbX detectors to ensure that this technology will remain available in the long term.

Picture: Particle measurement using PbSe detectors in tunnels

Ring from UV

Beyond Borders

The Florida-based company, Freedom Air Technologies, is making sure germs do not spread via air conditioners in the hot, humid Gulf Coast climate.

The up-and-coming startup has developed ring-shaped LED modules that can be easily integrated into the pipes of the units. Thanks to the reflective metal surface in the tubes, it is possible to neutralize more than 99.9% of all pathogens with just a few radiation sources.

»The modular concept was inspired by know-how from LASER COMPONENTS,« says Matt Robinson, General Manager. »We know how to achieve uniform dosage and which wavelength mix is best. This input was invaluable to the overall design process and enabled a solution that scales easily from single devices to comprehensive, complete systems.«

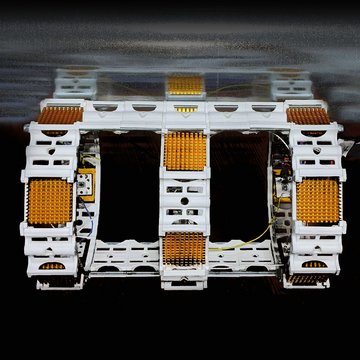

Picture: Ring-shaped LED modules for air conditioners

No chance for fire

Beyond Borders

FFE’s flame detectors detect sparks before fire or smoke even starts.

As a manufacturer, FFE relies on proven PbS technology, which offers both the spectral sensitivity and fast response time needed for this task. The detectors cover the long wavelengths that can be used to detect even the smallest sparks, regardless of the burning material.

At the same time, they also detect the short wavelengths to detect flames even through windowpanes. »Unlike many other manufacturers, we offer our customers additional steps such as a burn-in test so that the detectors can be calibrated and deployed more quickly,« says Tim Huylebrouck, product engineer at LASER COMPONENTS Germany.

Pictrue: Flame detectors detect sparks before fire or smoke even starts.

Nothing runs hot

Beyond Borders

Every second counts when it comes to measuring the temperature of a train’s wheels.

So-called »hot axle box detectors« determine on a moving train whether the wheels, wheel bearings, or brakes have heated up and pose a danger to passengers. The trains are often traveling at speeds of 300 km/h and more. The detectors have to distinguish cold from hot parts in just 72 µs. Only PbX technology can perform these types of measurements in such a short amount of time with the necessary sensitivity.

Picture: Hot axle box detectors in the German railway system

Products

Beyond Borders

Further product information:

Downloads

Beyond Borders