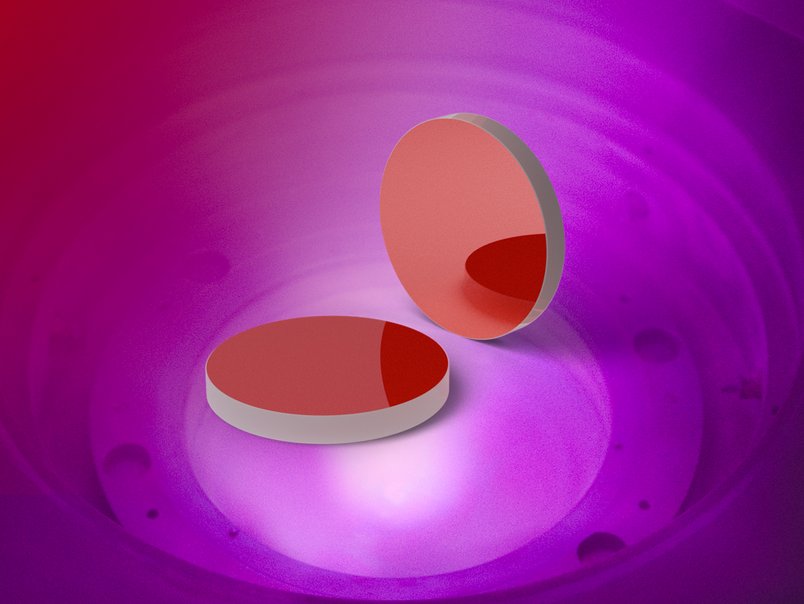

Waveplates – also known as "retardation plates" – are optical elements that create a phase shift in the transmitted light with the help of birefringency crystalline quartz.

A phase shift of 90° is referred to as a λ/4 plate, quarter wave plate, or a circular polarizer; whereas a phase difference of 180° is referred to as a λ/2 or half wave plate.

All waveplates are normally equipped with an AR coating that is optimized for one wavelength l. Uncoated plates are also available upon request.

There are three main types of waveplates: multiple order, low order, and zero order. The fundamental difference between these plates is the stability of the retardation tolerance across the wavelength range λ. This tolerance is a function of spectral range, product type, and design thickness.

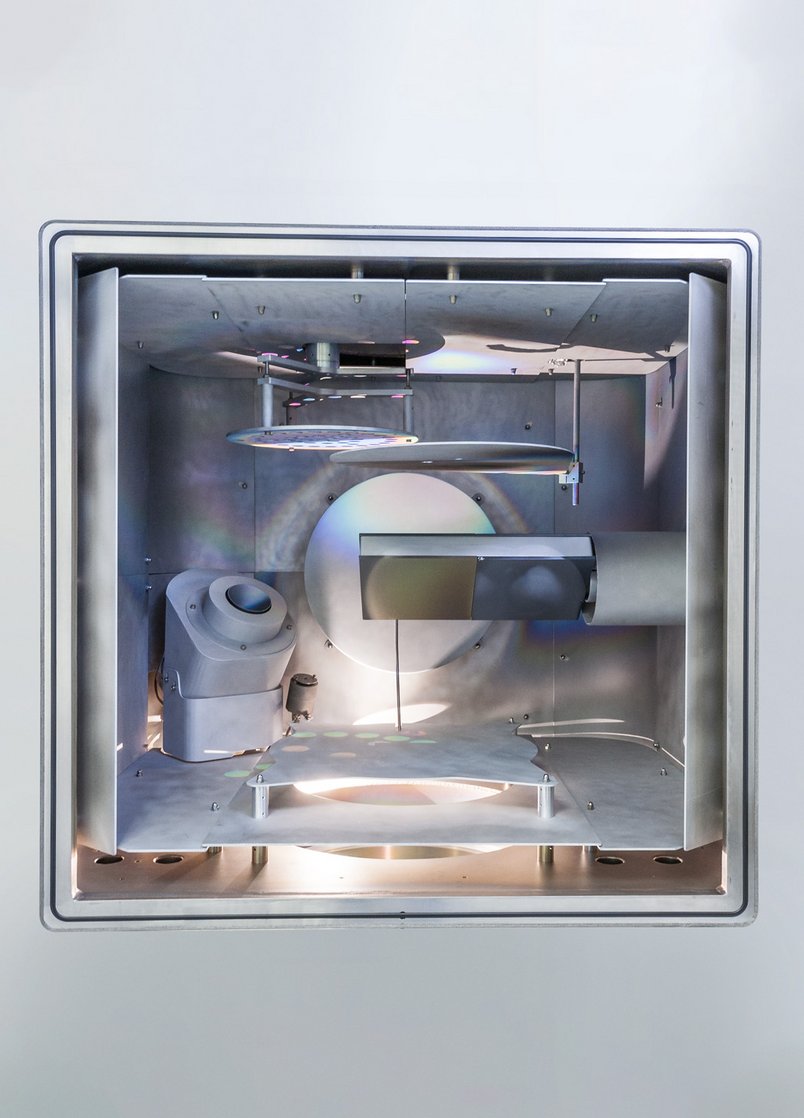

The thickness of the plates depends on the wavelength and the specified retardation. Typical thicknesses of retardation plates offered by LASER COMPONENTS include:

- Multiple order: 0.4 mm - 0.6 mm

- Low order: 0.1 mm - 0.25 mm

- Zero order (optically contacted): 0.8 mm - 1.2 mm

You will find details on this in the datasheets.

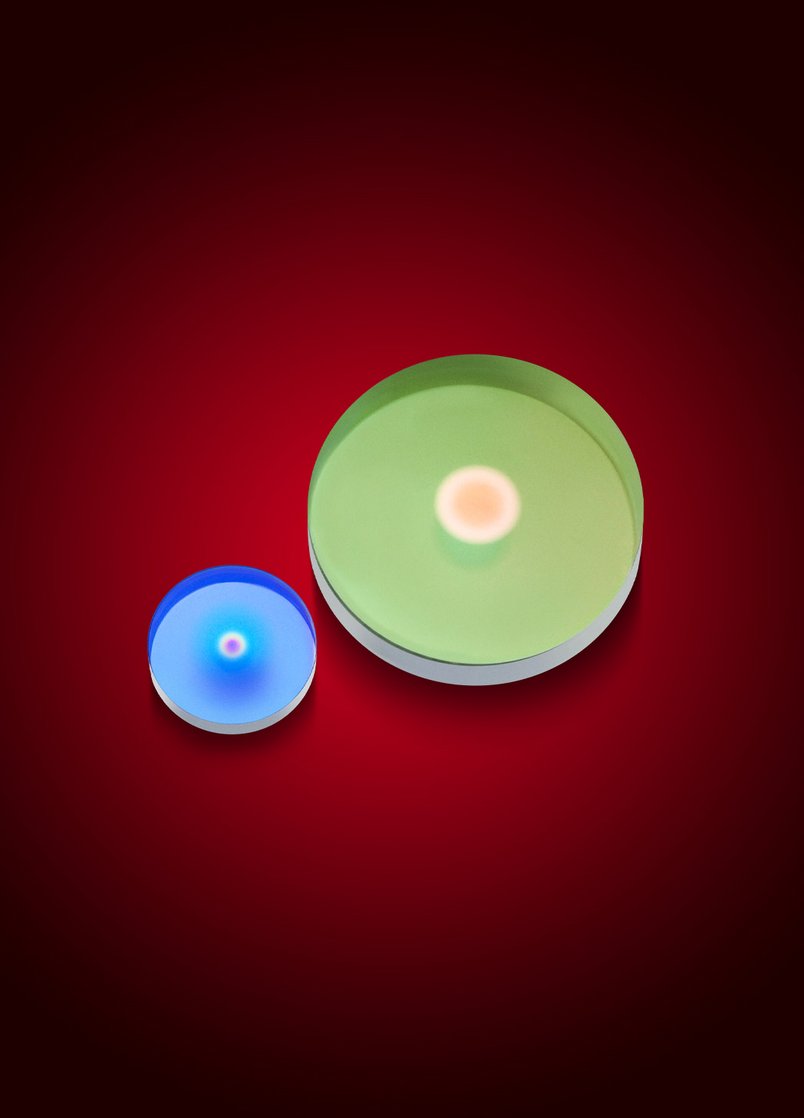

Dual/Harmonic Waveplates

Dual/harmonic waveplates are designed so that a defined phase shift can be reached for two wavelengths. The retardation can be selected differently for each single wavelength. In this way, the wavelength λ = 1064 nm, for example, can go through a phase shift of λ while the second wavelength, λ = 532 nm, experiences a phase shift of λ/2. The retardation plates otherwise correspond to multiple order plates.

Click here

News & Events

Laser Optics