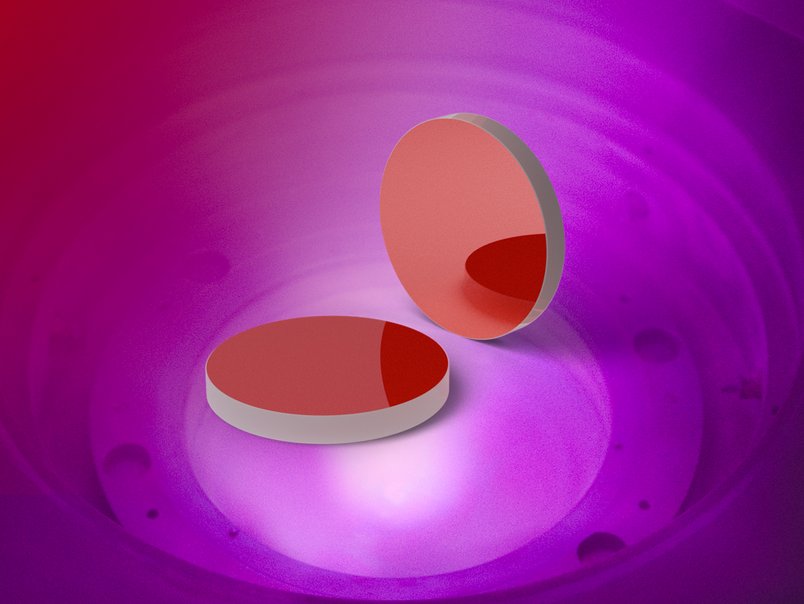

Minimize the reflection loss of p-polarized light.

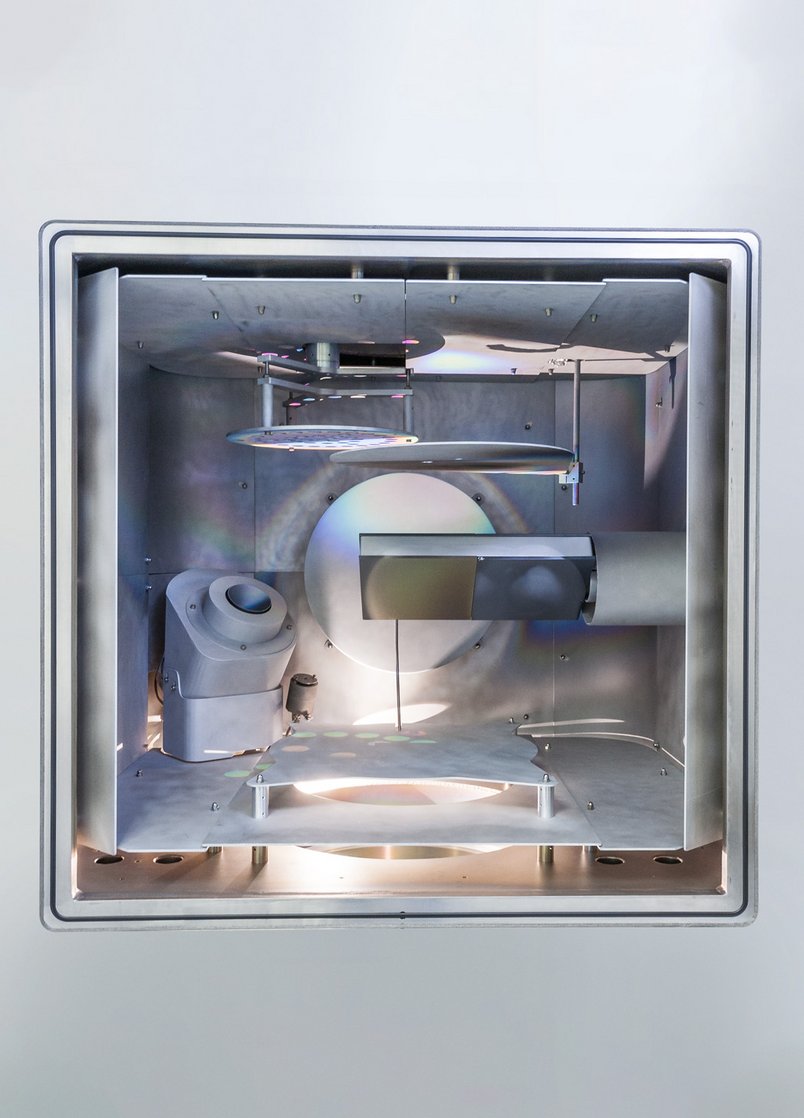

Brewster plates are used in optical devices in which minimal losses are important. The surfaces of the plates are arranged at Brewster’s angle (67.4° for ZnSe at 10.6 µm) to the optical axis, allowing the light polarized parallel to the plane of incidence (p-pol) to pass through completely. Perpendicularly polarized light (s-pol) is partially reflected (about 50%).

Brewster plates are used to generate linearly polarized light (e.g., in a laser resonator). They can also be used individually or stacked as a polarizer. During the laser processing of highly reflective metals, Brewster plates prevent back-reflected radiation from re-entering the resonator.

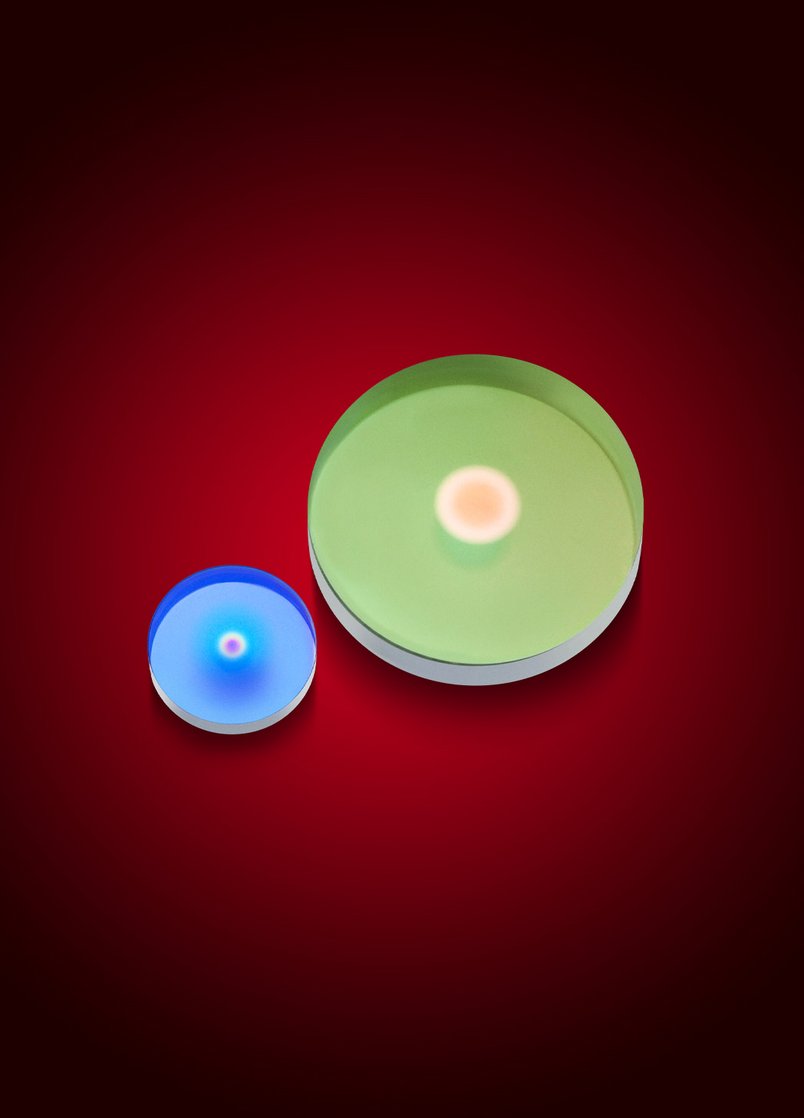

LASER COMPONENTS offers Brewster plates exclusively as rectangular components. Standard ZnSe Brewster plates are available at a length of 3 mm to 200 mm and a thickness of 1 mm to 10 mm. In order to achieve an appropriate beam quality, a few rules must be observed when using Brewster plates.

Rules for the use of Brewster plates

- They should be about 2.5 times as long as they are wide in order to give the incident beam a square profile.

- The ratio of length to thickness should be less than 30:1 because greater thickness ensures a better surface image.

- Brewster plates are normally used in pairs.

- A special coating on the front side can increase the reflection for s-pol to over 98% (enhanced Brewster plate; EWBZ).

For the optimum performance of a laser optic, the coating and substrate must be matched to the application. We will be happy to advise you and produce your customized design upon request.

Click here

News & Events

Laser Optics