But why Gaussian mirrors?

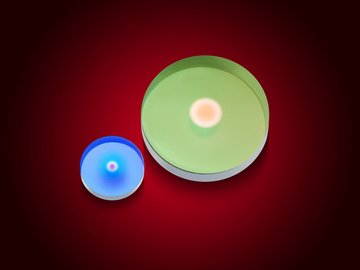

Gaussian mirrors, also known as Graded Reflectivity Mirrors (GRMs), play a crucial role in achieving high beam intensity with excellent beam quality. Their reflectivity decreases in a Gaussian manner from the center of the optic outwards. Instead of a convex coupler with uniform reflection, a GRM with a Gaussian reflection profile on the resonator side can be employed. This reflects primarily the central part of the beam, amplifying the central mode in the laser crystal. The result is a powerful laser beam with minimal divergence and exceptional far-field behavior.

This feature is particularly useful in applications involving frequency doubling to generate a desired wavelength. For instance, in laser material processing in the medical field or in LIDAR systems for atmospheric condition measurements, Gaussian mirrors serve as effective outcouplers.

In terms of applications, GRMs are always used in conjunction with monochromatic light. LASER COMPONENTS routinely manufactures Gaussian mirrors for a wavelength of 1064 nm and diameters ranging from 8 mm to 25.4 mm.

Ensuring a consistent reflection profile across various batches is the primary challenge in reproducible manufacturing. Rigorous quality control is crucial for these optics, surpassing conventional mirrors and lenses. In addition to standard quality checks, the unique reflective profile is thoroughly examined.

To meet this challenge, LASER COMPONENTS' development department has established an automated measurement station. Each Gaussian optic undergoes scrutiny, as a continuous wave laser scans the mirror along its diameter, documenting reflection values across the entire width. Only mirrors meeting all customer specifications in every criterion are dispatched.

Our customers can trust that each batch is consistent, and they have the means to verify this independently, because the real measurement curve accompanies every manufactured Gaussian optic, providing customers with tangible evidence of the mirror's performance.