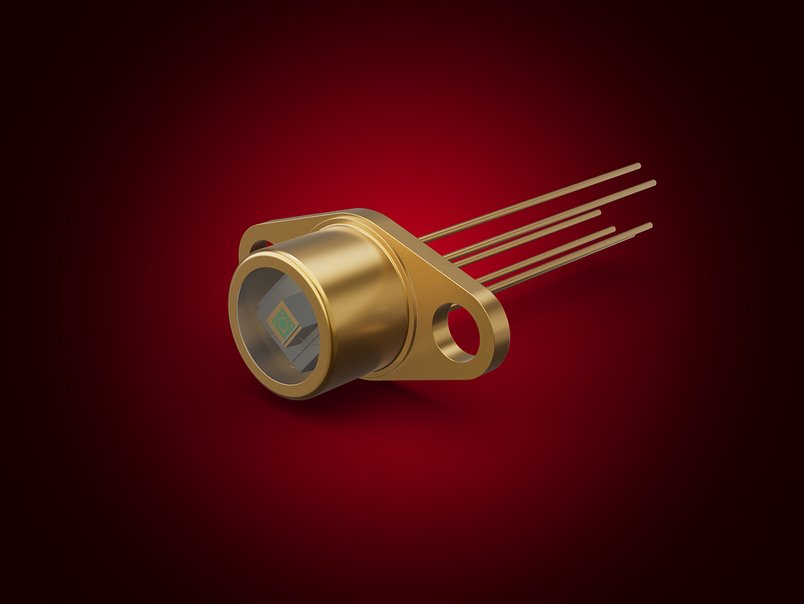

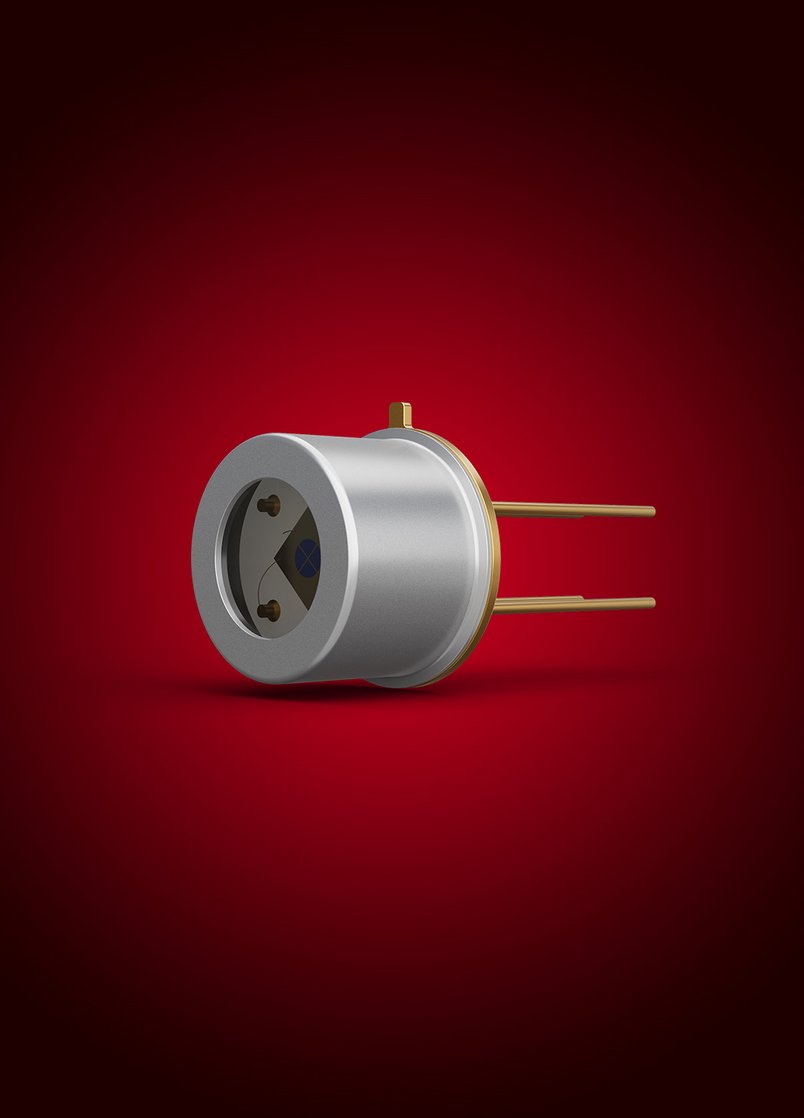

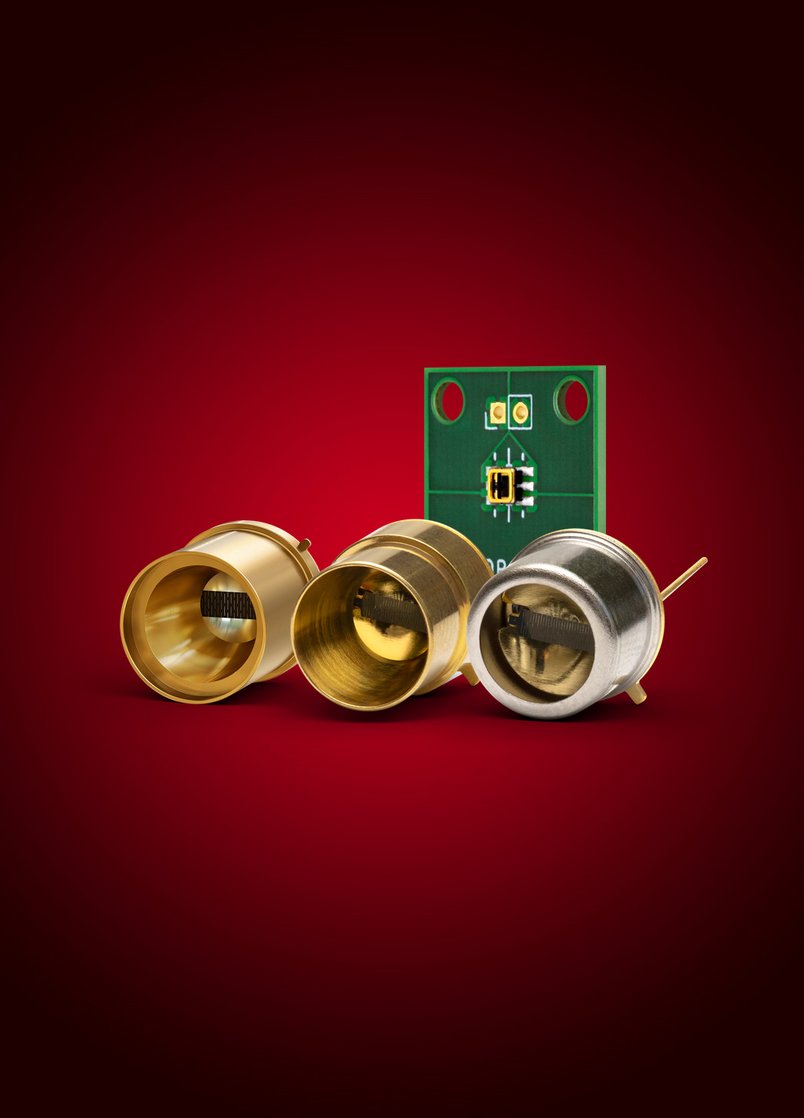

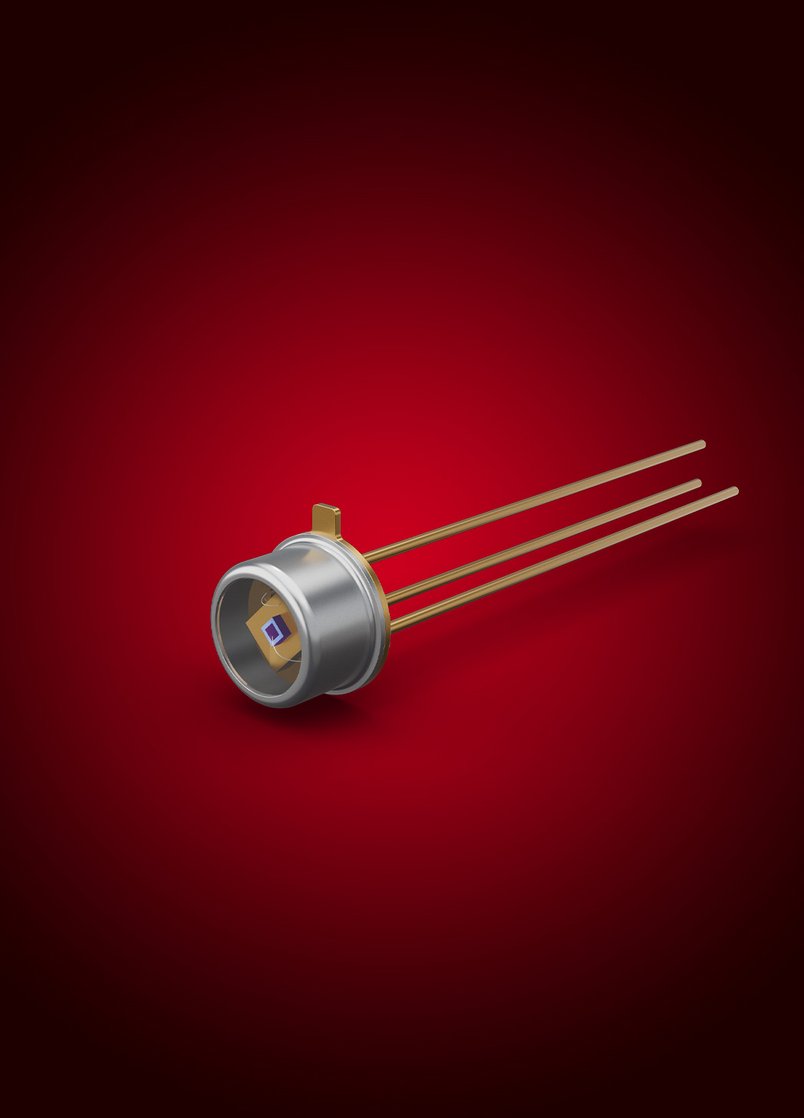

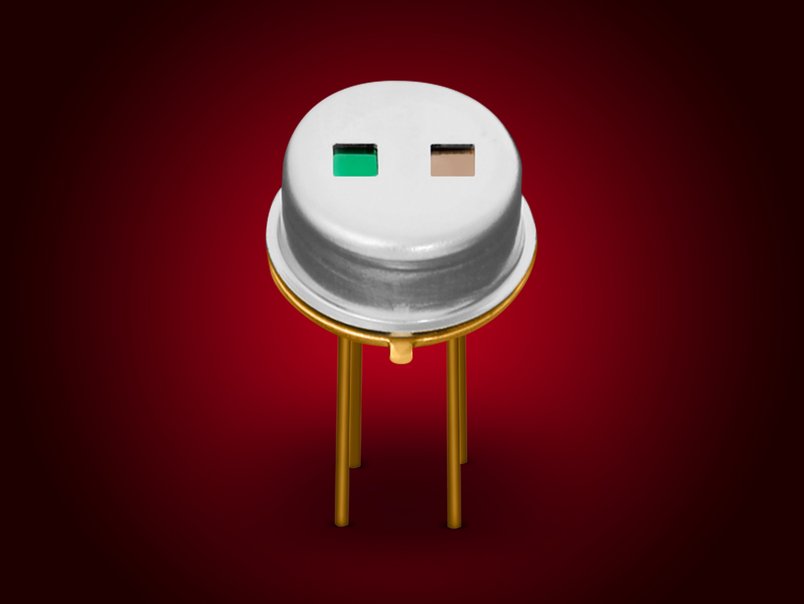

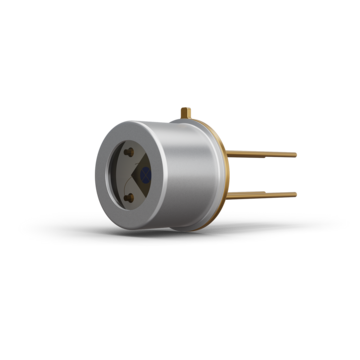

High-End Ultrathin LTO Detectors

The Advanced LTO Infrared Detectors combine the benefits of existing LTO and DLaTGS detectors. With this thin design, detector performance is improved due to a 4x better signal.

The Advanced LTO Infrared Detectors offer the freedom to choose the speed that suits each application. With transmission window options that allow for various configurations, such as a KBr window that transmits up to 30 μm and is also available with a parylene moisture-protective coating. High performance can be maintained up to 1 kHz, while the detector can be used out to approximately 10 kHz.

Additionally, the Advanced LTO Infrared Detectors are tested to operate at room temperature with no depoling concerns, as is typical for DLaTGS detectors. Under increasing IR flux, high linearity is observed, as well as a high Curie temperature of 610 °C.

The Advanced LTO Infrared Detectors are ideal for FTIR spectroscopy. They can also be appropriate for the measurement and monitoring of laser power at long wavelengths.

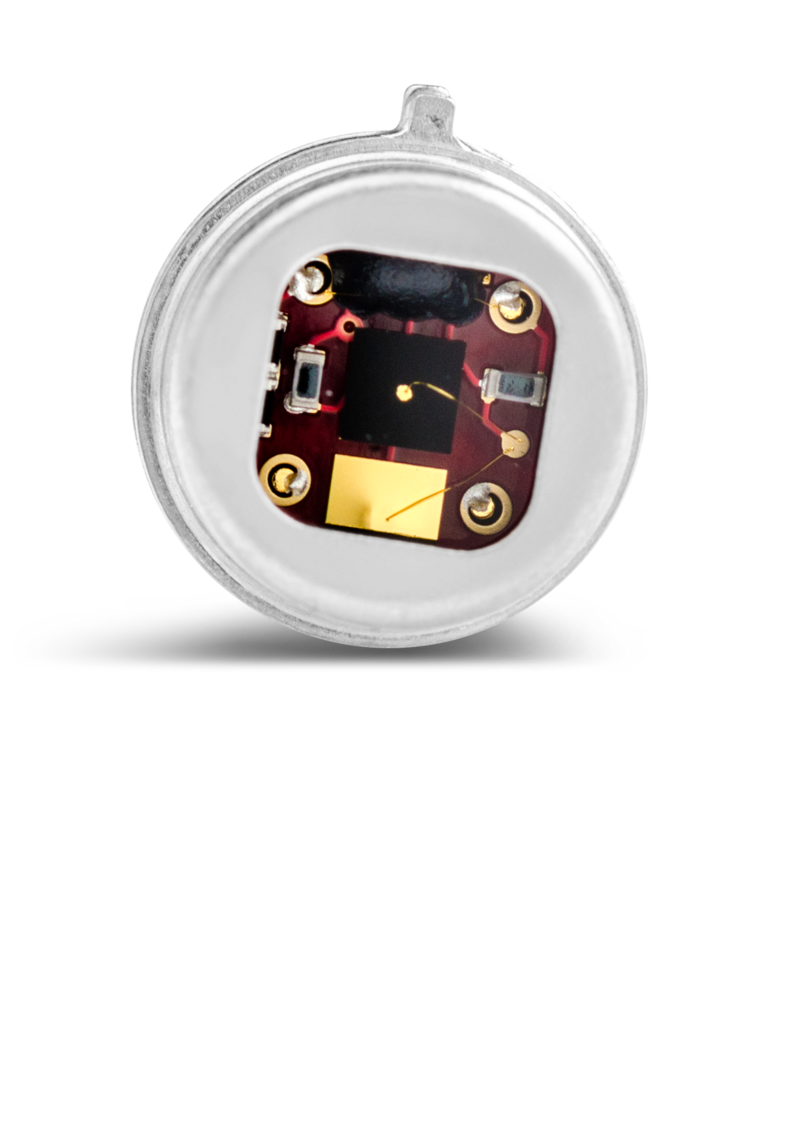

Bias Circuit

This is the suggested circuit for using these detectors.

The output signal is an analog voltage as shown in the bias circuit. The detector responds to changing incident IR flux and the response voltage rides on top of a DC offset voltage.

(Drawing version 01, created Jan 2024. Please download the FAQ file to find latest version).

Similar Products

Our IR Detectors

Panchromatic, photoconductive and thermal detectors

InGaAs PIN Photodiodes

Modern InGaAs PIN photodiodes are panchromatic and convert broadband light to photocurrents in the Vis-NIR range. Concretely speaking, this means a sensitivity range from 500 nm to 1700 nm for regular InGaAs and – in increments – up to 2600 nm for extended InGaAs. Variations for data transmission are not panchromatic.

PbS and PbSe Detectors

PbS is a standard SWIR semiconductor detector (1 - 3.3 µm) whereas PbSe is used in the MWIR range (1 - 4.7 µm when uncooled; up to 5.2 µm when cooled). Our lead salt detectors are photoconductive; the detector resistance is reduced during illumination. The crystal structure is polycrystalline and is produced via chemical deposition.

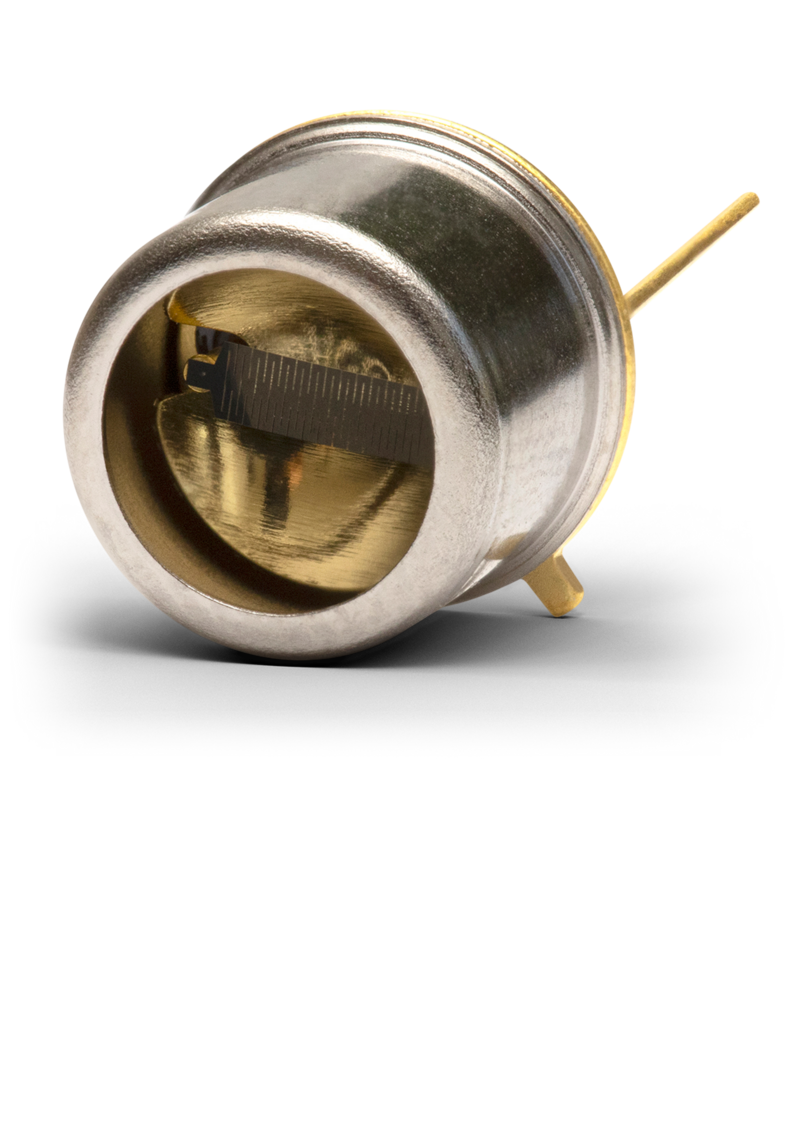

Pyroelectric IR Detectors

A pyroelectric IR detector is a thermal detector in that it responds to the change in heat (IR) absorbed on its surface. Thermal detectors are polychromatic with a very wide spectral bandwidth.

The nature of the pyroelectric effect is that in a highly-ordered crystal (or ceramic), a temperature change in the element causes its atoms to move slightly out of position. This rearranges its electrical charge, which is measured in the electrodes on its surface.

The pyroelectric effect is found in many materials. The most commonly-used materials are deuterated lanthanum α alanine-doped triglycine sulfate (DLaTGS) and lithium tantalate (LTO).

What is Your Challenge?

Beyond Borders

LASER COMPONENTS Germany GmbH

FAQs

WHAT YOU SHOULD KNOW ABOUT OUR Advanced LTO Detectors

What wavelength range can the detectors measure?

The ALT / ALUT detectors can be provided with a variety of infrared transmitting windows. Prominently used within the industry, the KBr window transmits out to 30 µm and is also available with a parylene moisture protective coating. BaF2, CaF2, CsI, CVD diamond, silicon, and ZnSe are some of the other IR windows available. For THz wavelengths the HDPE window transmits significantly past 60 µm. The complete list of IR windows available and their properties are described here

What is the output signal of the detector?

The output signal is an analog voltage as shown in the bias circuit. The detector responds to changing incident IR flux and the response voltage rides on top of a DC offset voltage.

What is the operating temperature and environment of these detectors?

The operating temperature is -20 to +55 °C. For applications where temperatures go beyond this range, LASER COMPONENTS can provide additional qualification testing to ensure reliable performance.

As with all optical elements, it is important to keep the detector in non-condensing environments. Some of the IR transmitting windows such as KBr and CsI are hygroscopic and high humidity exposure should be avoided.

What is the detection speed of the advanced pyroelectric detector?

The ALT / ALUT detectors are factory calibrated at 1 kHz and can be used out to approximately 10 kHz. The detectors have demonstrated a fast response to IR flux change which is a requirement for IR detectors used in FTIRs.

What are the main use cases for the ALT / ALUT detectors?

Typical use cases are for spectroscopic applications in FTIR instruments, and for THz radiation detection. However, more exotic use cases can be observed, such as the measurement and monitoring of laser power at long wavelengths.

What are the advantages of ALT / ALUT detectors compared to other IR detectors?

There are several advantages. As mentioned above these detectors do not require temperature stabilization or cooling. Additionally, the LTO based pyroelectric element has a high Curie temperature of about 610 °C and does not de-pole under high IR flux. The detectors have demonstrated excellent linearity in qualification tests with high optical power FTIRs; the linearity of the detector response under changing IR illumination is a key requirement for accuracy of the Fourier Transform mathematical operation. The ALT / ALUT detectors have large active detection areas compared to some quantum detectors that use immersion lenses.

Do the detectors need to be cooled?

No. The ALT / ALUT detectors are fabricated using lithium tantalate (LTO) pyroelectric material. LTO based detectors do not require temperature stabilization and cooling does not improve their performance.

News & Events

from the infrared world