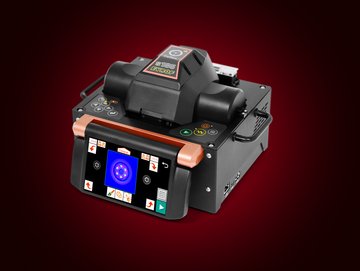

Fiber optic technology is evolving rapidly. Emerging applications and new fiber designs – such as multicore fibers, hollow-core fibers, and high-power fibers – are driving the need for innovative splicing solutions. Furukawa’s FITEL S185 fusion splicers demonstrate how decades of telecommunications expertise are being leveraged to meet the demands of modern industrial and specialty fiber applications.

LASER COMPONENTS recently published a white paper by manufacturer Furukawa Electric that provides an in-depth look at how the FITEL S185 fusion splicer family addresses current challenges through advanced splicing technology.

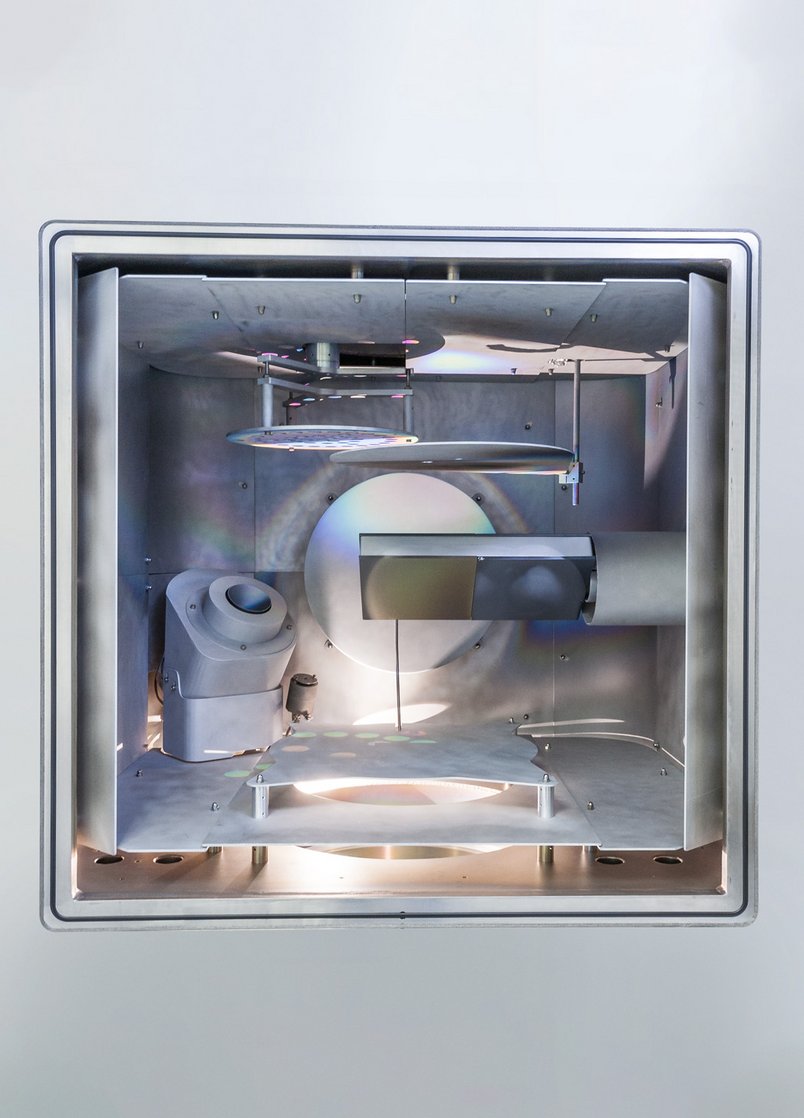

During the splicing process, fibers are aligned along six axes. In addition to the X, Y, and Z axes, the system compensates for rotational alignment (θ) as well as pitch and yaw. Even slight rotational deviations can cause significant attenuation losses in multicore fibers. In high-performance fiber applications, incorrect angular alignment can also lead to localized heating, which in extreme cases may damage the fiber.

Furukawa also optimized the fusion process itself by enhancing its Ring-of-Fire (ROF) technology with STA2D (Sequential Triangular Asymmetric Arc Discharging). Unlike conventional ROF, STA2D ignites the arc discharges between the three electrodes one after another rather than simultaniously. This controlled and directed heat distribution allows for targeted fiber shaping, which creates a highly precise fusion point with minimal attenuation and homogeneous glass transitions. The result is significantly improved signal quality. At the same time, these splices are exceptionally robust and resistant to mechanical stress, making them well suited for demanding applications.

»The FITEL S185 series fusion splicers represent the state of the art,« says Dr. Andreas Hornsteiner, Product Manager at LASER COMPONENTS. »Which of the numerous product variants is ultimately the best fit depends on the specific application and its requirements. Our product engineers work closely with customers to select the right fusion splicer for each project.«