Optics for Lasers of the Future

High Power Requires State-of-the-Art Coating Methods

When the first lasers were developed almost 60 years ago, the power limits reached into the milliwatt range. Today, the optics industry uses continuous wave lasers that emit several kilowatts; in addition, research centers use enormous pulsed laser devices that emit several hundred terawatts. Contrary to the general trend toward miniaturization, laser optics are getting larger and larger at increasing output power levels. For optics manufacturers such as LASER COMPONENTS, there is great potential in precision optics with high damage thresholds.

State-of-the Art Coating MethodS

for low absorbtion

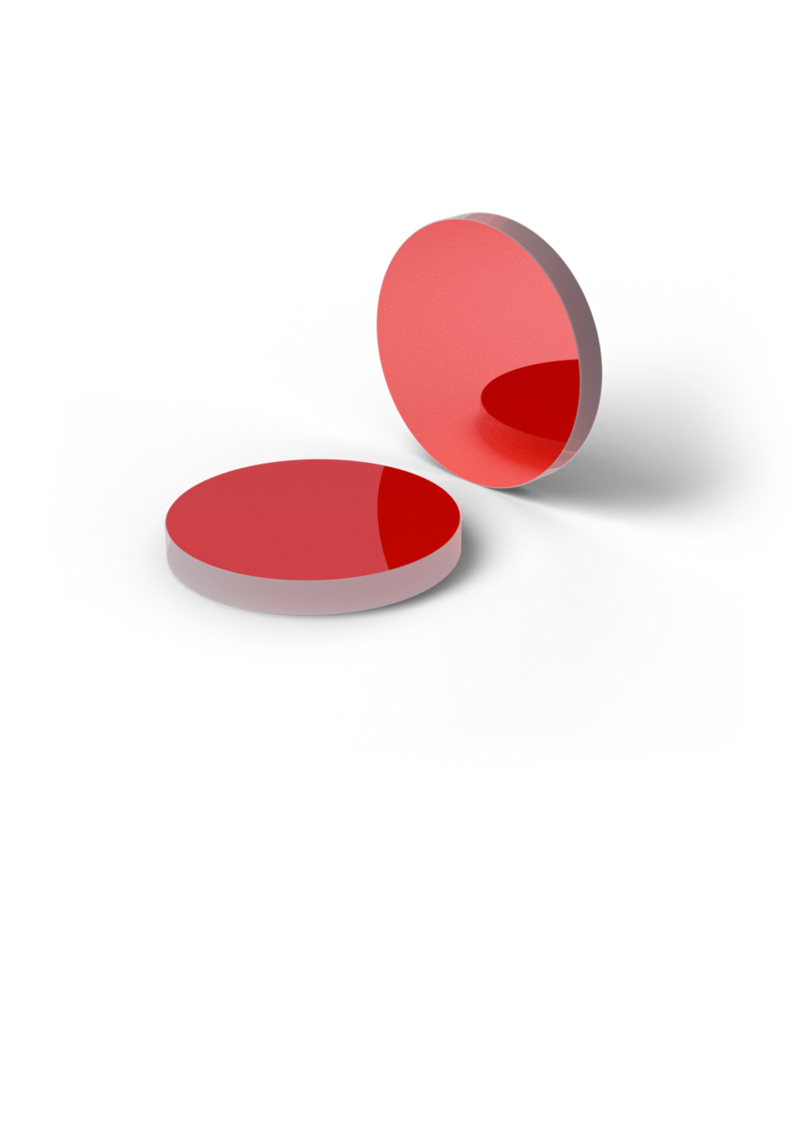

High laser output power requires low absorption of laser optics. The optics industry uses continuous wave (cw) lasers for welding and cutting. Producing the optics required for this purpose is a complex process because the high output power requires particularly robust components.

Compared to other areas of application, absorption in the ppm range has serious consequences in high-power lasers: The absorbed light produces heat in the substrate and coating. Damage can occur because optical components do not conduct heat well. Temperature fluctuations can lead to the focal point “wandering” and no longer remaining in the processing plane. This is referred to as a thermal lens.

How the absorption affects the laser beam can be determined via the calorimetric measurement of the surface temperature or via a reference beam.

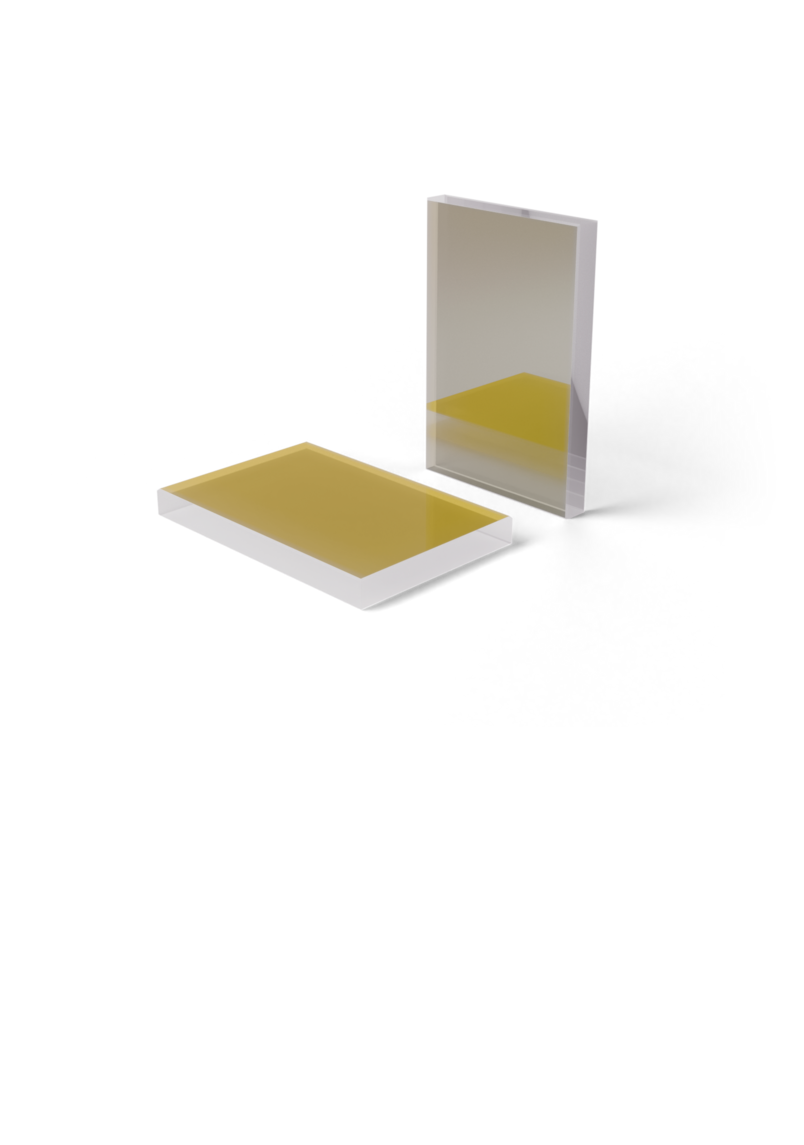

What can you do to solve the problem of absorption? With substrates that are low in OH and an optimal coating selection, optics with very low absorption rates can be produced. The use of so-called TLC optics™ is relatively new. A method that has been used successfully for decades in infrared optics is here transferred to laser light.

Optics for the Largest Lasers in the World

Best LiDT

Lasers in research

Nuclear fusion and cancer research require high-energy lasers in the megawatt and petawatt range that support science in making breakthroughs. There are a handful of gigantic facilities in use. The most well-known facility in Europe is most likely the Laser Mégajoule near Bordeaux. In 2014, the first of 22 beamlines went into operation. Another one will be added each year until 2025. The lasers used in these facilities break all records in terms of dimension with which we are familiar in the optics industry. This becomes apparent from the size of the building alone. Each of the four laser halls is 100 m long and 30 m wide. The number of components used is also immense: for complex beam guidance, for example, 10,000 optics are required in various sizes [1].

Investments to meet customer needs

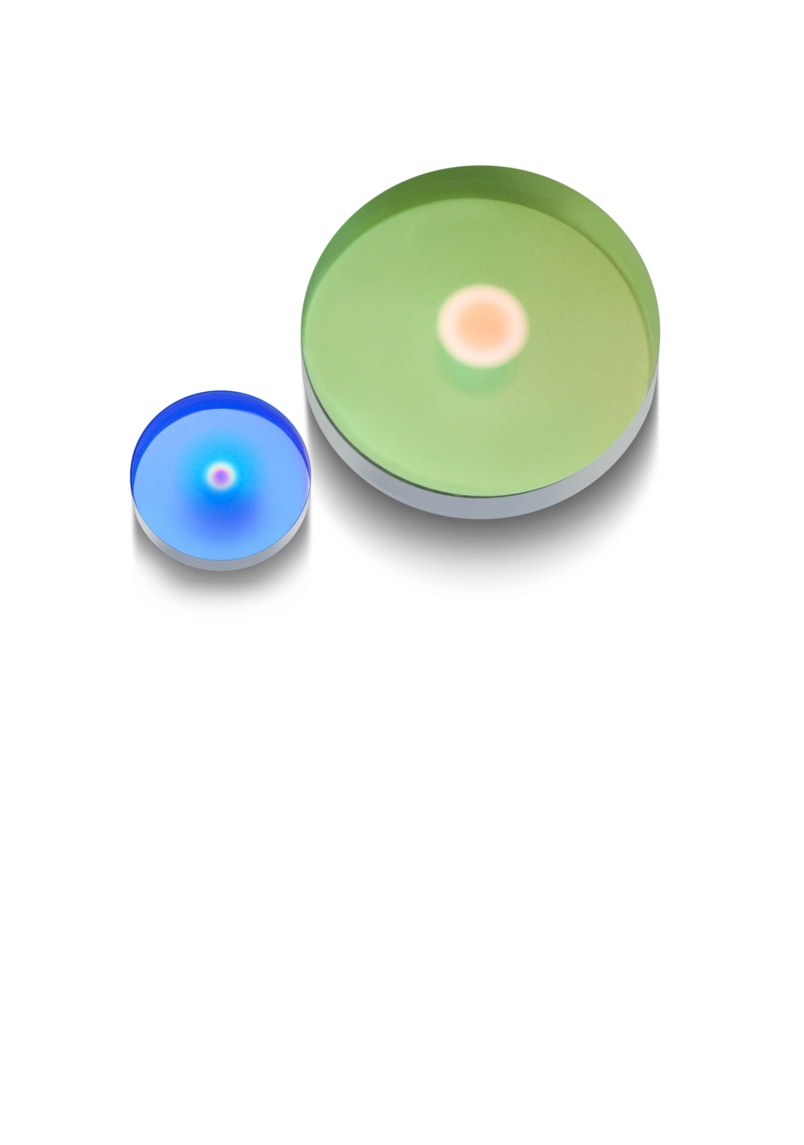

LASER COMPONENTS manufactures optics with diameters of up to 390 mm for these scientific institutions. To carry this out successfully, it is first necessary to select the right substrate and coating material. Not all substrates are low in absorption, suited for the desired sizes, and at the same time smooth enough. The surface roughness may only be a few Ångström at the most, and the surface figure must range in the area of l/10. Furthermore, a coater is required that can handle large substrates and ensure highly homogeneous coatings even on large diameters. We check this regularly by taking distribution measurements.

High Quality

Laser Optics

In good shape, even under pressure

In plasma-assisted processes, the packing density of the vapor-deposited coatings is particularly high. Depending on the diameter-to-thickness ratio of the substrates, this can lead to slight deformations in the substrates. It is possible to correct this effect by taking the proper measures: Either it is necessary to use an appropriately pre-bent substrate or to apply another coating to the backside of the substrate that reverses this effect. It is crucial to have a production team that is experienced in practical applications and knows how to get the desired results.

Experience and scientific curiosity

With our high-quality laser optics, we deliver practice-based solutions for the challenges of the present; however, LASER COMPONENTS also always has the future in mind: Together with industrial partners and renowned research institutes, we collaborate nationwide on developing the technologies and processes of tomorrow.

This combination of development, production, experience, and research curiosity is the secret of our success at LASER COMPONENTS. It allows us to meet even the most complex technical requirements. It also provides us the security of tackling each new challenge: Our sales engineers and developers work closely with our customers on innovative solutions for applications of the future.

Product Selection

call our experts to select the right product for your application

Click here

Downloads

Beyond Borders